3-15

HRN216 MAINTENANCE

18. VALVE CLEARANCE

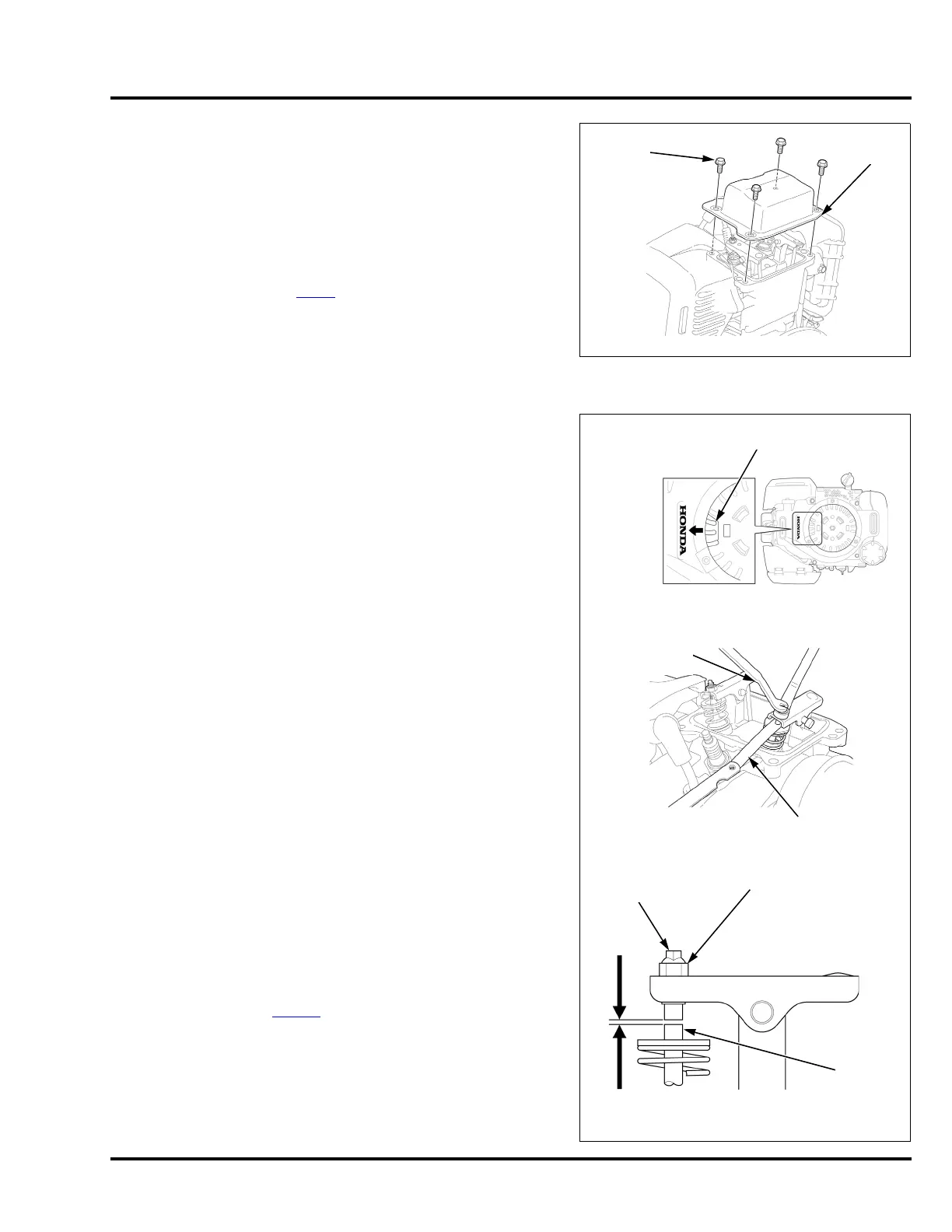

Valve clearance inspection and adjustment must be performed

with the engine cold.

CHECK

1. Disconnect the spark plug cap.

2. Remove the fan cover (P. 7 -3

).

3. Remove the head cover bolts, and the head cover.

The cylinder head cover is made of very thin metal and

becomes bent or damaged during removal. If the head cover is removed, replace it with a new one to prevent oil

leaks.

4. Set the engine to top dead center (TDC) of the compression

stroke (both valves fully closed). Rotate the flywheel clockwise

until the magnet inside the flywheel faces the direction of the

cylinder head. This will position the engine at TDC of either the

compression or exhaust stroke. Rotate 360 degrees if

necessary. If it is hard to rotate the flywheel, remove the spark

plug.

5. Insert a feeler gauge between the valve adjusting screw and

valve stem to measure the valve clearance.

If adjustment is necessary, proceed as follows.

ADJUSTMENT

1. Hold the valve adjusting screw using the special tool and loosen

the valve adjusting screw lock nut.

2. Turn the adjusting screw to obtain the specified clearance.

3. Hold the valve adjusting screw and retighten the valve adjusting

lock nut to the specified torque.

4. Recheck the valve clearance, and if necessary, readjust the

clearance.

5. Apply Hondabond HT (or equivalent) to the cylinder head cover

installation surface (P. 1 0- 6

).

Installation is in the reverse order of removal.

VALVE CLEARANCE:

IN: 0.10 ± 0.02 mm

EX: 0.10 ± 0.02 mm

TOOL:

Valve adjusting wrench, 3 mm 07908-KE90200

TORQUE:

Valve adjusting lock nut: 8 N•m (5.9 ft-lb)

TORQUE:

Cylinder head cover bolt: 12 N•m (9 ft-lb)

HEAD

COVER

BOLT (4)

HEAD

COVER

FLYWHEEL

To increase valve clearance, screw out.

To decrease valve clearance, screw in.

FEELER

GAUGE

VALVE

ADJUSTING

SCREW

VALVE

STEM

VALVE

STEM

LOCK NUT

VALVE

ADJUSTING

WRENCH