MICROPROCESSOR-BASED/DDC FUNDAMENTALS

143

ENGINEERING MANUAL OF AUTOMATIC CONTROL

PROGRAMMING CATEGORIES

Programming of microcomputer-based controllers can be

subdivided into four discrete categories:

1. Configuration programming.

2. System initialization programming.

3. Data file programming.

4. Custom control programming.

Some controllers require all four levels of program entry while

other controllers, used for standardized applications, require

fewer levels.

CONFIGURATION PROGRAMMING

Configuration programming consists of selecting which

preprogrammed control sequence to use. It requires the

selection of hardware and/or software packages to match the

application requirements. Configuration programming can be

as simple as selecting a specific controller model that matches

the specific application requirements, or it can require keyboard

selection of the proper software options in a more complex

controller. Universal type controllers, typically applied as zone-

level controllers for VAV or other terminal units, are usually

preprogrammed with several control sequences resident in

memory. In these cases, configuration programming requires

selecting the proper control sequence to match the application

through device strapping or keyboard code entry.

SYSTEM INITIALIZATION PROGRAMMING

System initialization programming consists of entering

appropriate startup values using a keypad or a keyboard. Startup

data parameters include setpoint, throttling range, gain, reset

time, time of day, occupancy time, and night setback

temperature. These data are equivalent to the settings on a

mechanical control system, but there are usually more items

because of the added functionality of the digital control system.

DATA FILE PROGRAMMING

Data file programming may or may not be required

depending on whether the controller is a fixed-function or

variable-function device. Zone-level controllers are typically

fixed function since the applications and control sequences

are generally standardized. In these controllers, the input

terminals are dedicated to a specific sensor type and range,

and the output terminals are dedicated to a control relay or

specific type of actuator. The need for data files is minimized.

The processor always knows what to look for as it scans those

points, and it knows how to process the data.

System-level controllers are variable-function and are more

universal in application. These controllers must be able to

perform a wide variety of control sequences with a broad range

of sensor input types and control output signals. System-level

controllers require more extensive data file programming. For

the controller to properly process input data, for example, it

must know if the point type is analog or digital. If the point is

analog, the controller must know the sensor type, the range,

whether or not the input value is linear, whether or not alarm

limits are assigned, what the high and low alarm limit values

are if limits are assigned, and if there is a lockout point. See

Table 2. If the point is digital, the controller must know its

normal state (open or closed), whether the given state is an

alarm state or merely a status condition, and whether or not

the condition triggers an event-initiated program.

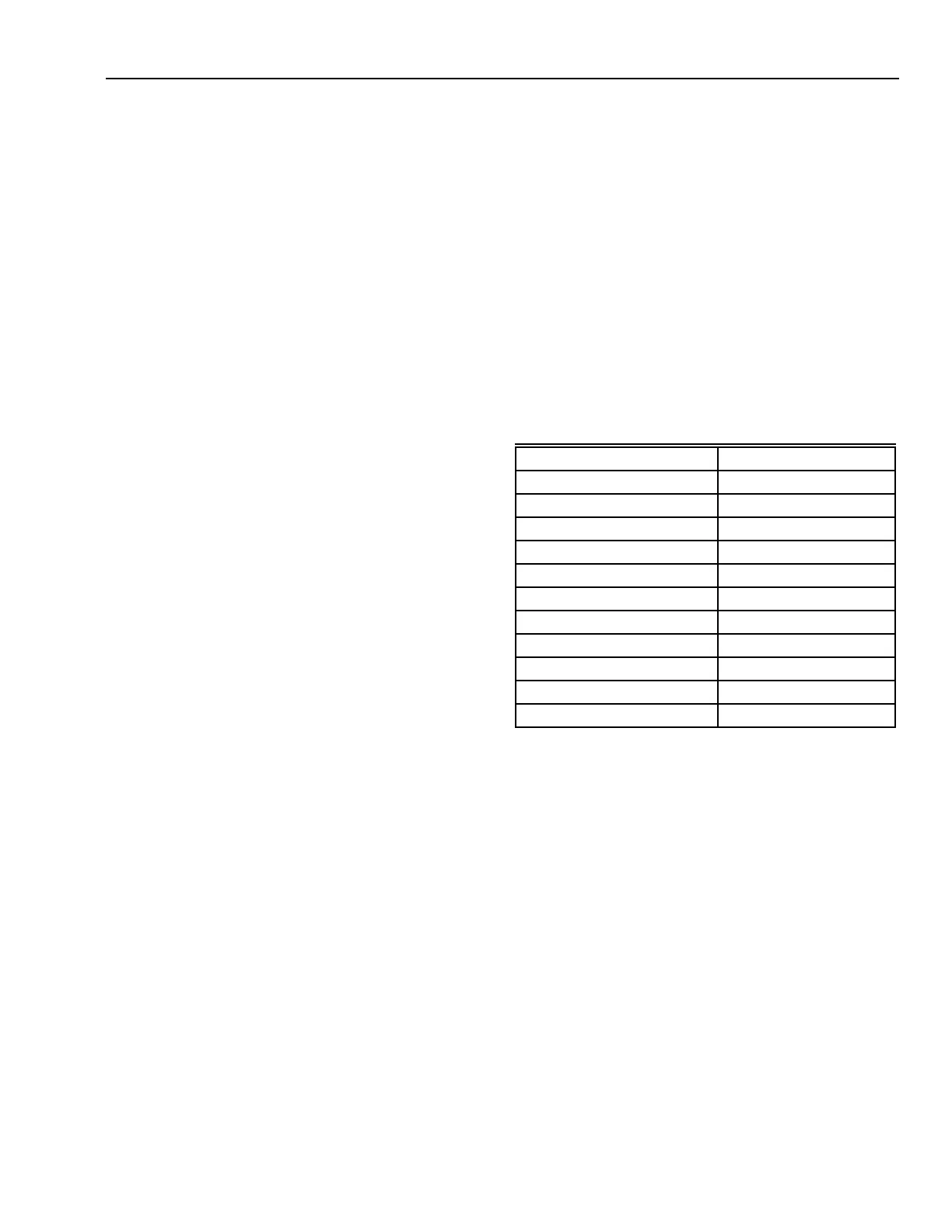

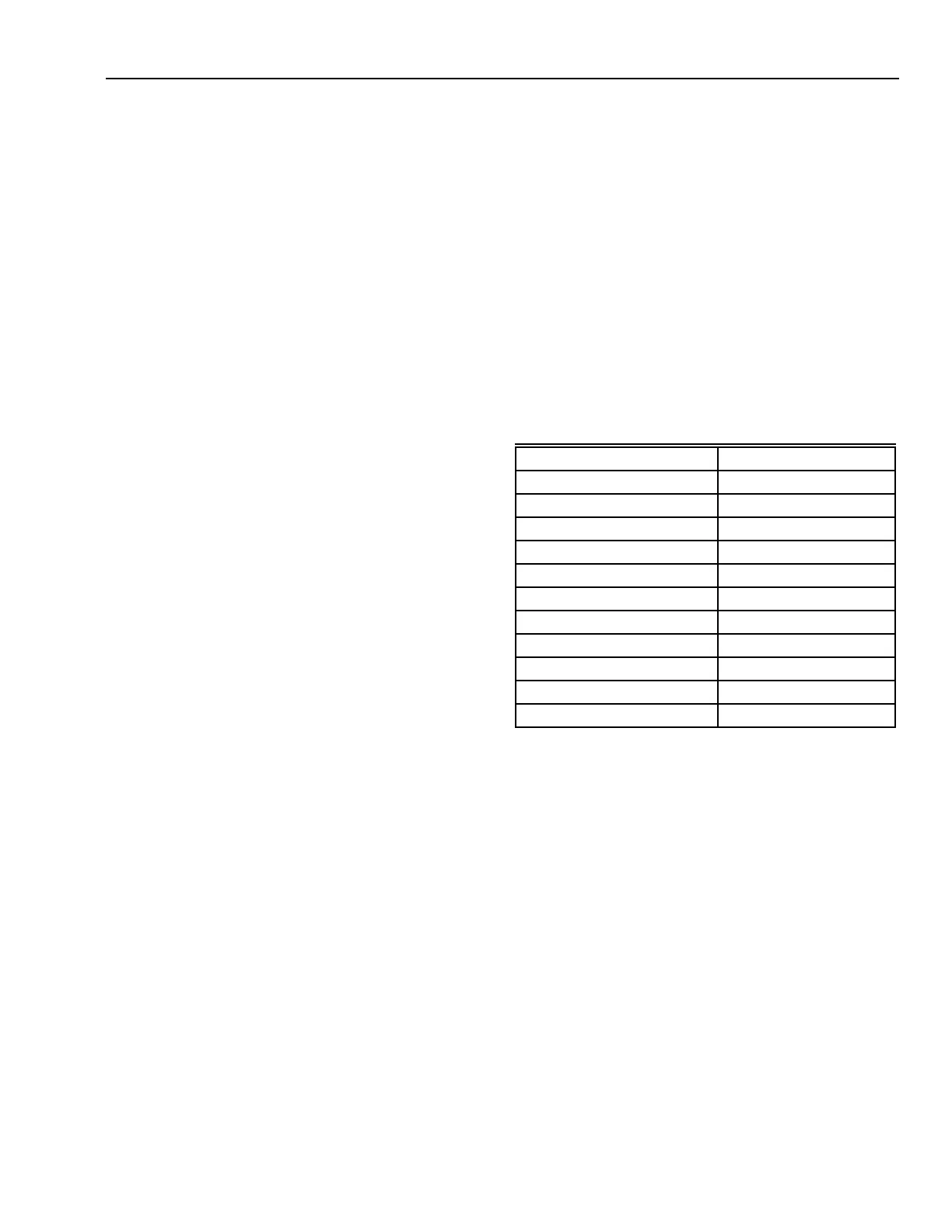

Table 2. Typical Data File for Analog Input.

Point Address User Address

Point type Regular or calculation

Sensor Platinum (0 to 100F)

Physical terminal assigned 16

Use code Cold deck dry bulb

Engineering unit F

Decimal places for display XXX.X

High limit 70.0

Low limit 40.0

Alarm lockout point Point address

Point descriptor Cold deck temperature

Alarm priority Critical

CUSTOM CONTROL PROGRAMMING

Custom control programming is the most involved

programming category. Custom control programming requires

a step-by-step procedure that closely resembles standard

computer programming. A macro view of the basic tasks is

shown in Figure 13.

Loading...

Loading...