ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

374

CONTROL PRINCIPLES FOR STEAM

HEATING DEVICES

GENERAL

To control a steam supplied device, the system design should

include valves and other equipment required to produce the

amount of heat needed at design conditions. In addition, the

system should be capable of controlling a steady flow of heat

directly related to the demands of the thermostat or other

controller at load conditions from 0 to 100 percent.

To design a steam system that is capable of controlling the

various radiators and coils in a building, the pressure relationships

between the various elements of a steam heating system must be

analyzed under various load and system conditions.

MODULATING STEAM COIL PERFORMANCE

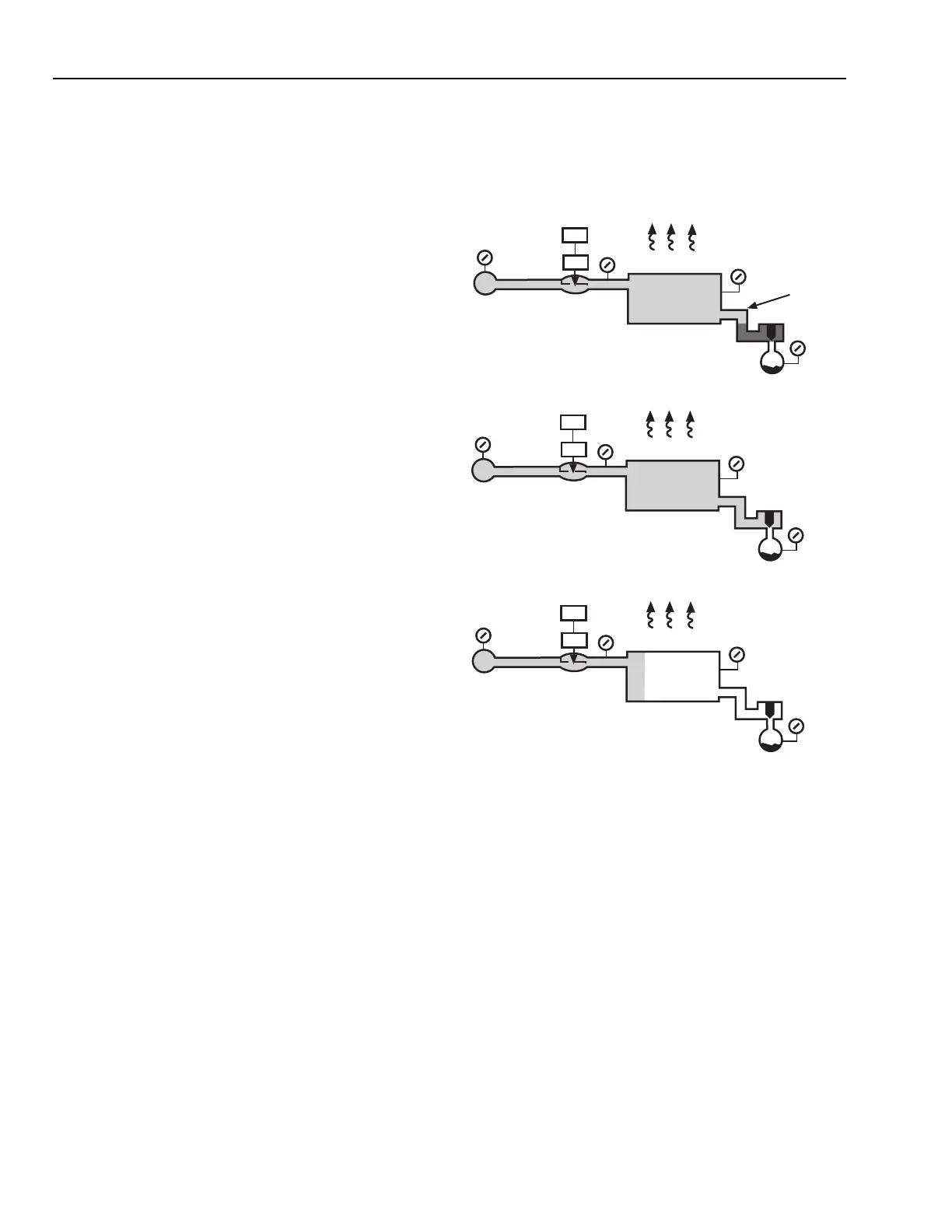

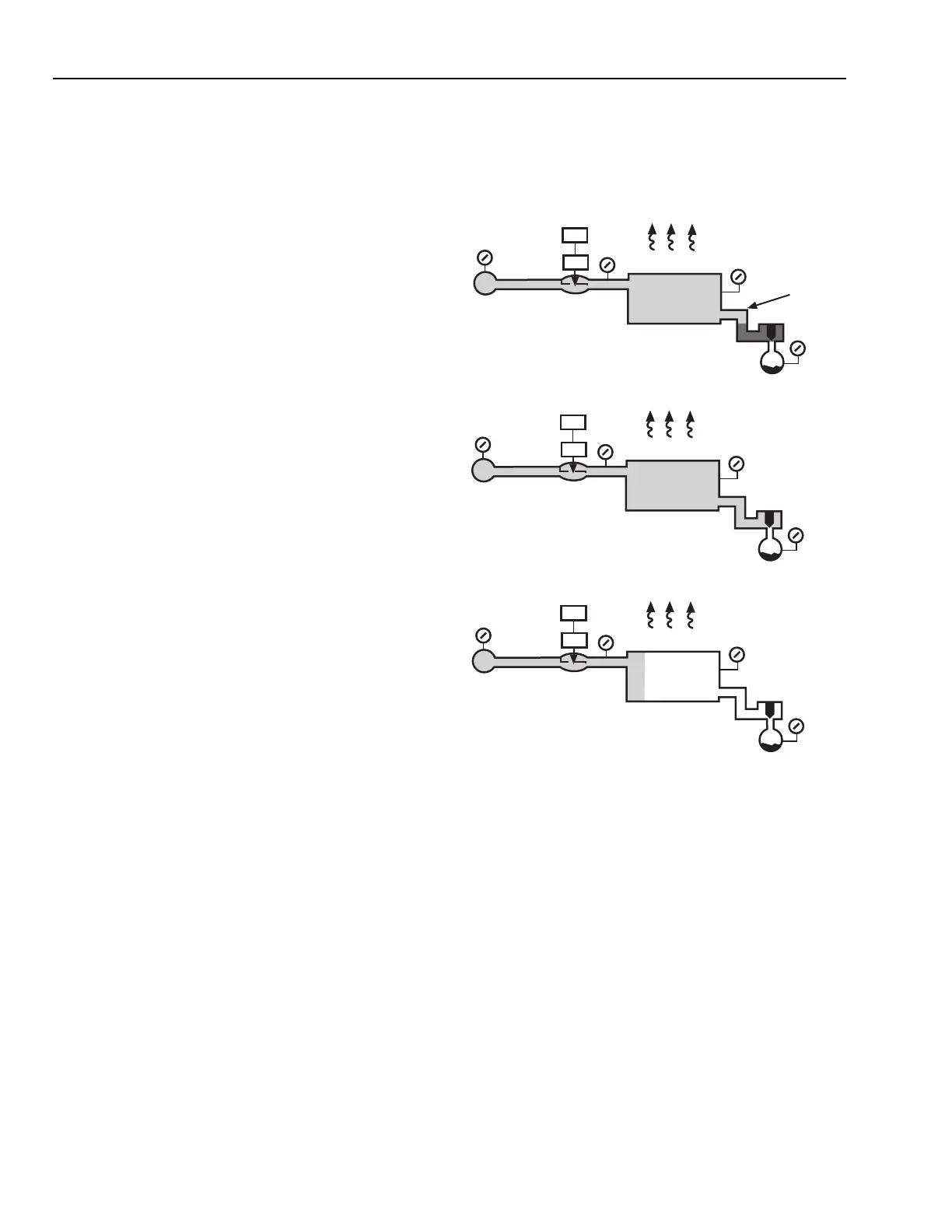

Figures 114 and 115 show a steam coil supplied from a 5

psig steam main, controlled by an oversized modulating valve

(Fig. 114) or a correctly sized modulating valve (Fig. 115), and

discharging condensate to the return through a trap. The figures

demonstrate the importance of proper sizing of the modulating

valve and the ability of the valve to control the output of the

coil. Refer to the Valve Selection and Sizing section for valve

sizing procedures.

Oversized Valve

In Figure 114A a large valve is used to ensure 4 psi in the

coil. When the valve is full open, the coil is full of steam and

the output is 100,000 Btuh. The return header and trap are also

full of steam keeping the trap closed much of the time. The

trap opens slightly when water accumulates around the

thermostatic element allowing the condensate into the return

mains. The pressure drop through the valve and coil is small,

but large across the trap.

Figure 114B shows the pressure relationship and heat output

as the modulating valve closes to the half-open position. The

smaller opening in the valve requires 4 psi to get the steam

through the valve, called a 4 psi drop across the valve. This

leaves 1 psi in the steam coil header. Although the thermostat

has signaled to the valve to cut heat output in half, the coil is

still full of steam and the heat output is only reduced by 5

percent. The reduction is because of the difference in

temperature of 4 psi steam compared to 1 psi steam, assuming

50F air temperature entering the coil. The trap drop is 0.9 psi.

Most of the pressure drop between the supply and the return

mains is now across the steam valve. The portion of the

modulating valve stroke between half open and full open

reduces the heat output only 5 percent.

Figure 114C shows the quarter-open valve position. Half of

the coil surface is starved of steam, the heat output is reduced

to about half of the original value and the trap is full open. All

of the steam has been condensed in the coil before reaching the

trap. Virtually all of the drop between the supply and return

mains is dissipated through the control valve.

Fig. 114. Control Results with Oversized Valve.

The conclusions reached from Figure 114 are:

1. The sum of the individual pressure drops across the valve,

coil, and trap equals the pressure difference between the

supply and return mains.

2. Heat output changes little due to pressure change within

the coil, as long as the coil is full of steam.

3. Heat output changes little until the valve assumes most

of the pressure drop between supply and return mains.

4. Heat output from the coil is reduced by starving a part

of the coil surface of steam and allowing the surface to

cool off.

NOTE: Steam distributing coils allow reduced output without

the return end becoming cold.

THERMOSTAT

VALVE

STEAM

MAIN

RISER

MODULATING

VALVE

FULL OPEN

RETURN MAIN

AT ATMOSPHERIC

PRESSURE

RETURN

HEADER

3.9 PSI

4.0 PSI

COIL 0.1 PSI DROP

TRAP

3.9 PSI

0 PSI

5 PSI

HEAT OUTPUT

100,000 BTU/HR

DROP

THERMOSTAT

VALVE

STEAM

MAIN

RISER

MODULATING

VALVE

1/2 OPEN

RETURN MAIN

AT ATMOSPHERIC

PRESSURE

0.9 PSI

1.0 PSI

COIL 0.1 PSI DROP

TRAP

0.9 PSI

0 PSI

5 PSI

HEAT OUTPUT

95,000 BTU/HR

DROP

THERMOSTAT

VALVE

STEAM

MAIN

RISER

MODULATING

VALVE

1/4 OPEN

RETURN MAIN

AT ATMOSPHERIC

PRESSURE

0.02 PSI

0.02 PSI

COIL NO DROP

TRAP

0.02 PSI

0 PSI

5 PSI

HEAT OUTPUT

52,000 BTU/HR

DROP

A. FULL-OPEN VALVE.

B. HALF-OPEN VALVE.

C. QUARTER-OPEN VALVE.

4.98 PSI

DROP

4 PSI

DROP

1.0 PSI

DROP

M15077

Loading...

Loading...