ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

347

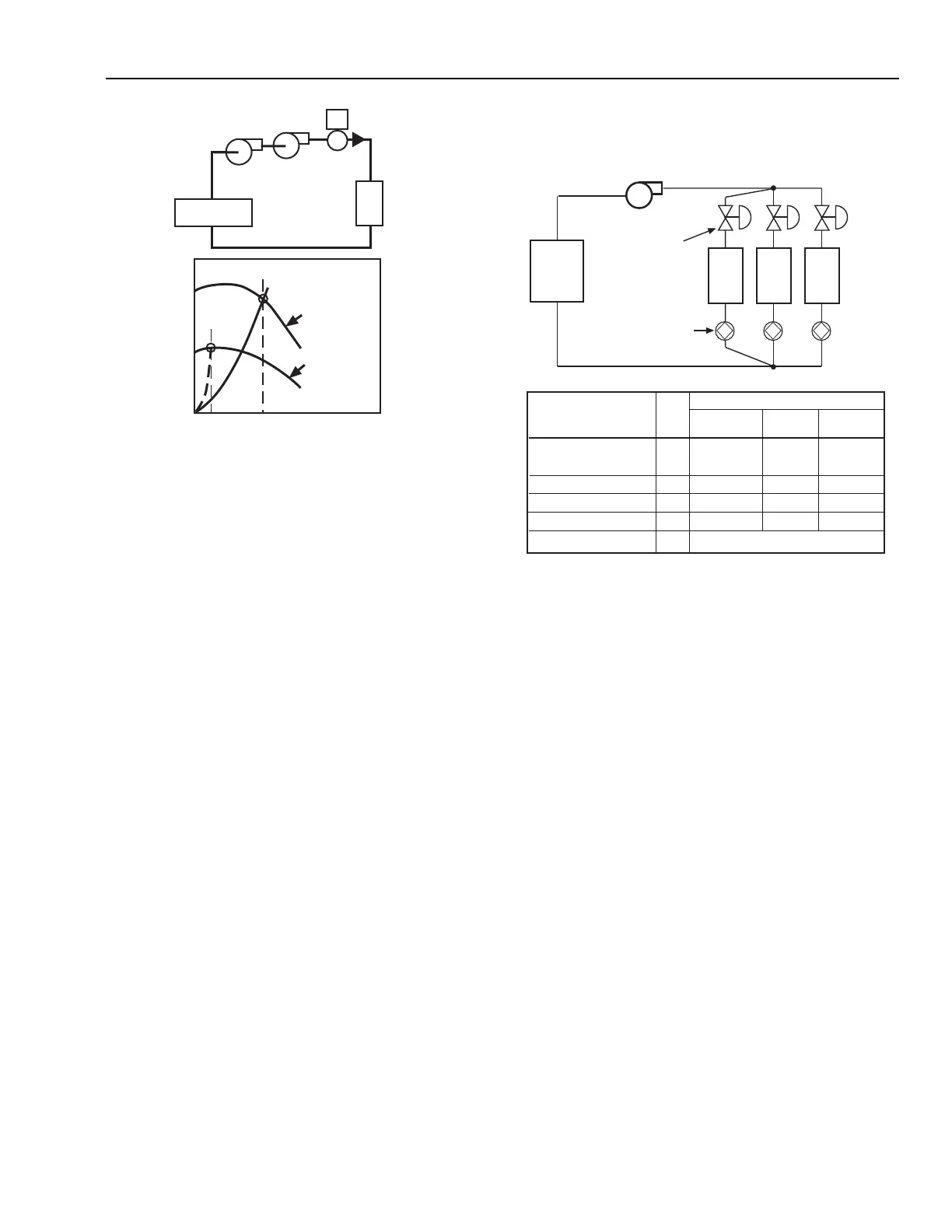

Fig. 67. System Operation for Series Pumps.

Dual Pump Curves

For pumps in parallel (Fig. 66), assuming two identical

pumps, the curve is developed using the following formula:

gpm

3

=(gpm

1

) x 2 for any h

1

Where:

gpm

3

=Total flow for both pumps

gpm

1

= gpm of one pump

h

1

= Head in ft for Pump 1 at gpm

1

for any point

on pump curve

For pumps in series (Fig. 67), assuming two identical pumps,

the curve is developed using the following formula:

h

3

=(h

1

) x 2 for any gpm

1

Where:

h

3

=Total head in ft for both pumps

h

1

= Head in ft for one pump at gpm

1

(for any

point on Pump 1 curve)

DISTRIBUTION SYSTEM FUNDAMENTALS

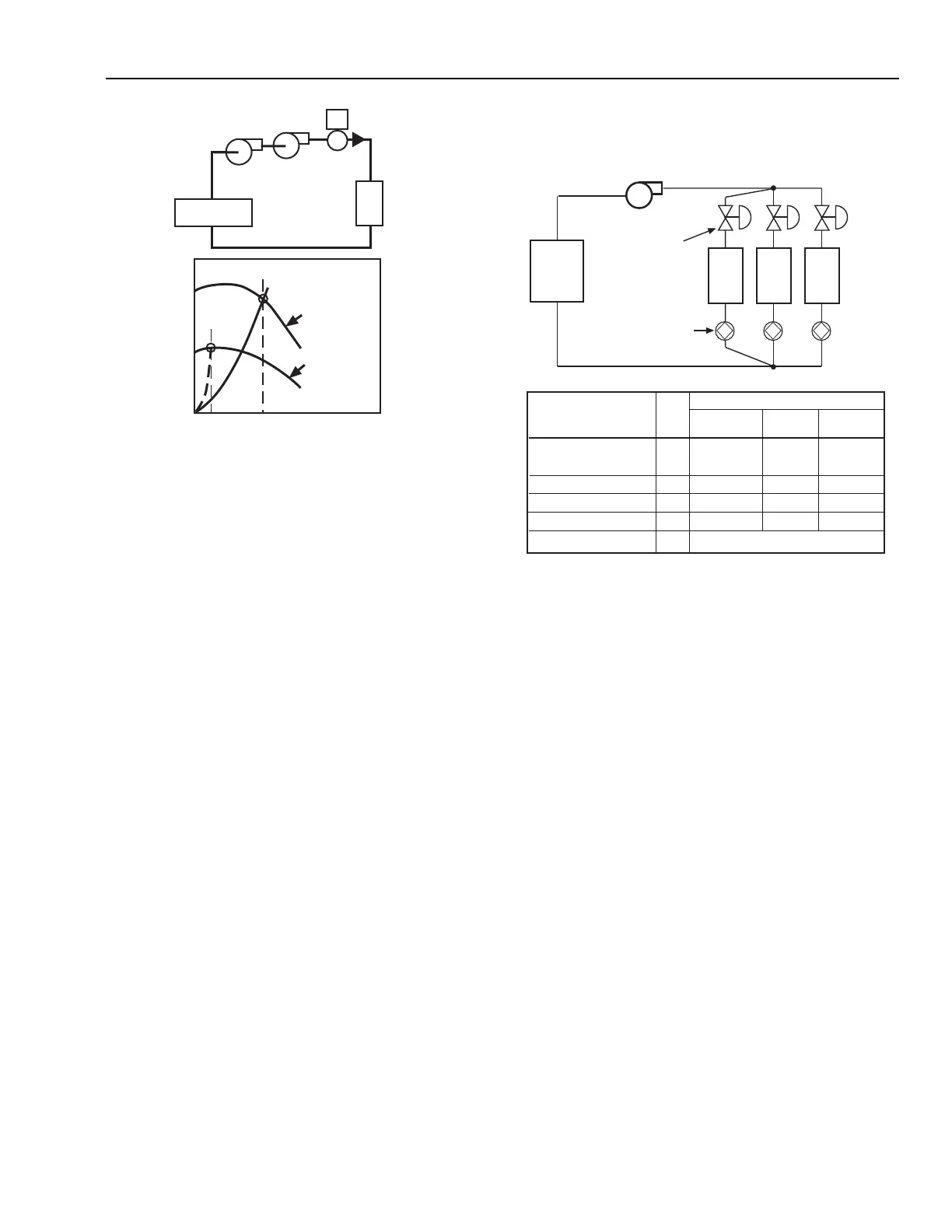

Figure 68 illustrates a closed system where static head

(pressure within the system with pump off) does not need to be

considered as long as all components are rated for the static

head encountered. The pump provides force to overcome the

pressure drop through the system and valves control the flow

and pressure through the system. Figure 69 shows a graph of

the system and pump curves for design load and reduced load

conditions. The system curve indicates the pressure drop

through the system (with the control valves full open) at various

flow rates. The pump curve shows the pump output pressure at

various flow rates. Flow always follows the pump curve.

SERIES

PUMPS

CONTROL

VALVE(S)

LOAD

2 PUMPS

1 PUMP

24%

LOAD

FULL

LOAD

FLOW

HEAT

EXCHANGER

HEAD

C2410

Fig. 68. Simplified Water Distribution System.

In Figure 68 the flow and pressure considerations are:

1. The flow through the heating or cooling source, the supply

piping, and the return piping (40 gpm) is the same as the

sum of the flows through the three coil circuits:

10 + 12 + 18 = 40 gpm.

2. Design pressure drop (head loss) includes the drop

through the heating or cooling source, supply piping,

return piping, and the highest of the three coil circuits:

23 + (10 + 11) = 44 ft.

NOTE: In this example, Coil 1 and 3 balancing valves

balance each load loop at the 21 ft design for

Loop 2. If the actual coil and control valve

drops were less than the design maximum

values, the actual balancing valve effects

would be greater.

In this example the pump must handle 40 gpm against a total

head of 44 ft (19 psi) as shown in Figure 69. (This curve is

taken from actual pump tests). The design drop across the valve

is 11 ft (4.5 psi) with the valve fully open.

If Figure 68 is a heating system, as the loads reduce valves

V1, V2, and V3 start to close. Hot water flow must be reduced

to about 15 percent of full flow (6 gpm) to reduce heat output

to 50 percent. As flow through the coil is reduced the water

takes longer to pass through the coil and, therefore, gives up

more heat to the air.

HEATING/

COOLING

SOURCE

1

V1

2

V2

3

V3

HEATING

OR

COOLING

COILS

PUMP

SUPPLY PIPING

RETURN PIPING

CONTROL

VALVES

BALANCING

VALVES

M15054

* SUM OF SOURCE AND PIPING (23 FT) AND LOOP 2 (21 FT) = 44

DESIGN PRESSURE DROP IN FEET

FLOW

GPM

COIL & PIPING

CONTROL

VALVE

BALANCING

VALVE

ITEM

40

23* _ _

HEATING OR COOLING

SOURCE AND

DISTRIBUTION PIPING

COIL 1 LOOP

COIL 2 LOOP

COIL 3 LOOP

TOTAL FLOW AND DROP

10 8 11 2

12 10* 11* 0

18 7 11 3

40 44*

Loading...

Loading...