16

www.honeywell.com

The LCD should display a pressure reading of close to ‘0.00. The recorder is now ready for

functional checks.

*Note: All of the function checks assume that the instrument has been configured with a

default setup.

Use the MI Logo (push button) or an optionally installed push button to scroll through the display

list(s) and stop at the live pressure reading. Without having made a pressure connec

tion, the LCD

will display a value very close to zero, typically, within +/- 0.4% of full scale.

Connect a pressure source to the external ¼” NPT pressure connector, apply a varying pressure

(less than full scale) and observe an increase or decease in the LCD’s reading as the pressure

varies. An automatic ten-minute time-out ensures that if a recorder left in a live reading, the

recorder will r

eturn to the sample measurement mode to conserve battery power. Continue to

scroll through the remaining display list items until the recorder has returned to the sample

measurement mode.

Instrument Setup

The following items are critical in the recorder’s operation and proper configuration.

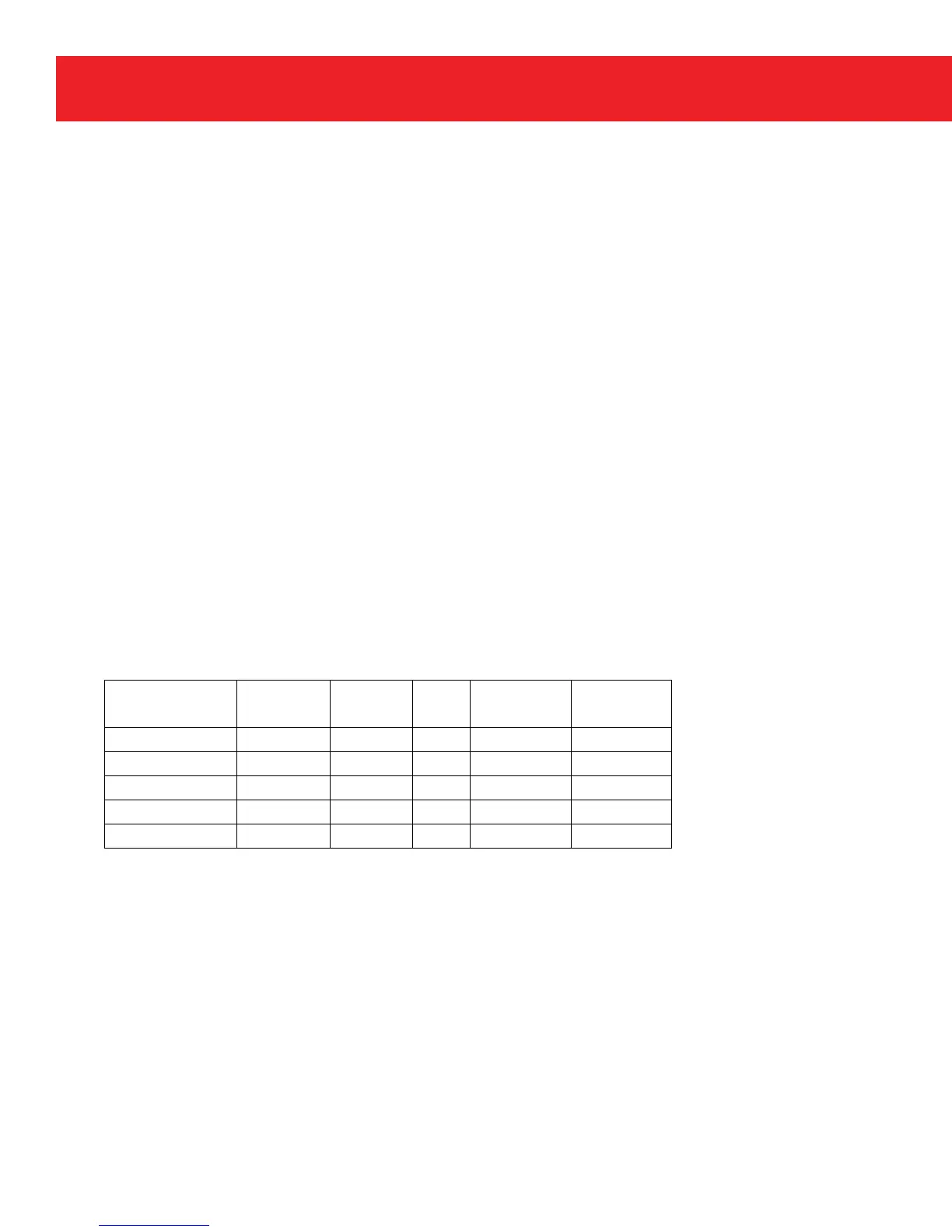

Instrument Configuration

Item 576 configures what the recorder will record, that is, pressure(s) and te

mperature data, if

equipped, e.g. P, PP, PPP, PT, or PPPT.

Pressure

Site IDs

Site identification items 580 and 581, used to identify the recorder to the associated software.

Items 580 and 581 Site IDs are preprogrammed using the recorder’s serial number, set by the

factory prior to shipping, but may be changed to meet company’s requirement. Site IDs must

remain unique, that is, no tw

o recorders should have the same Site ID numbers.

Transducer

Range

Xducer

Range Unit Coefficients

Board

Coefficients

Pressure (P1) 570

572

549

301~332 178~181

Pressure (P2) 571

573

550

341~372 441~444

Pressure (P3) 412

419

408

150~155 445~448

605~630

Temperature 551

Loading...

Loading...