MAINTENANCE

HPR130 Manual Gas Instruction Manual 5-17

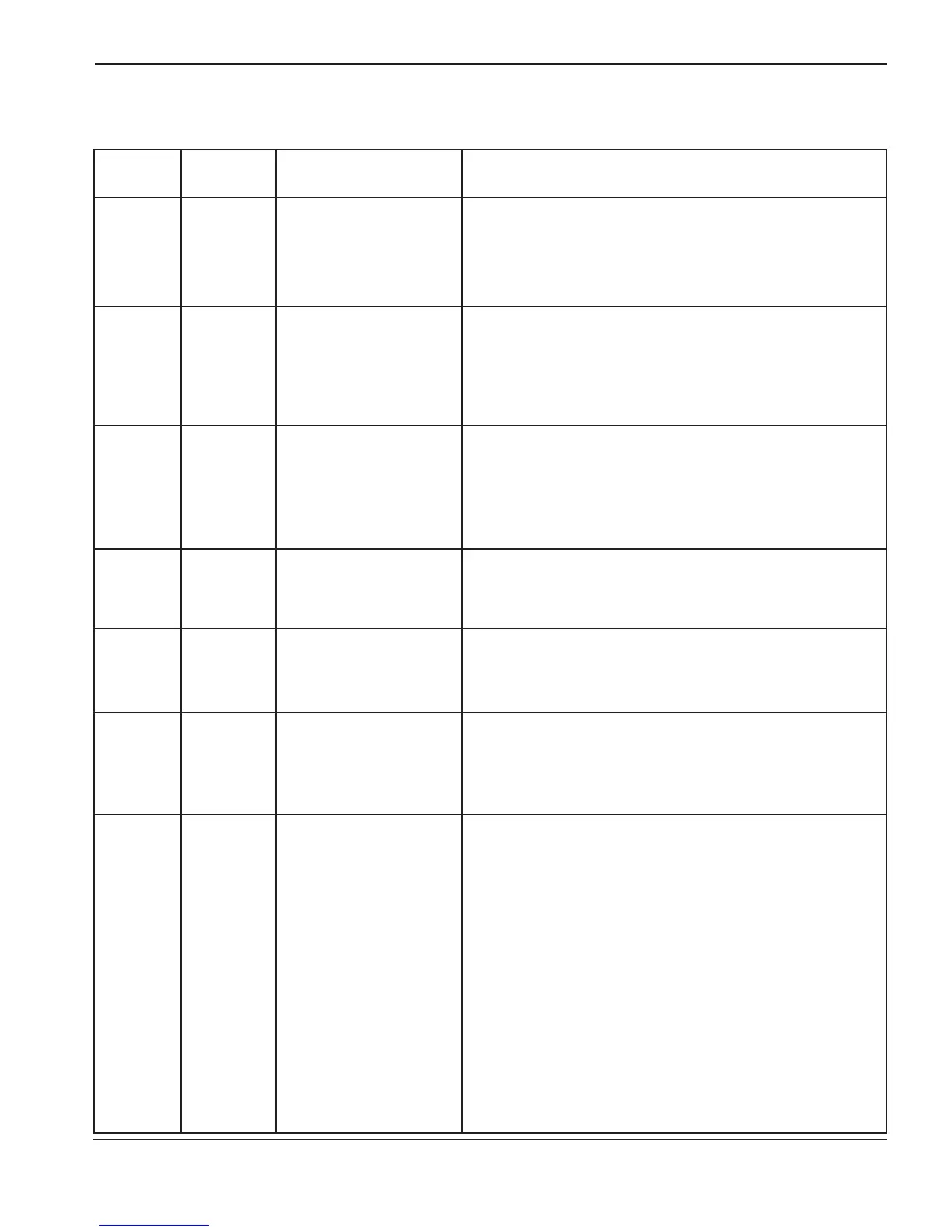

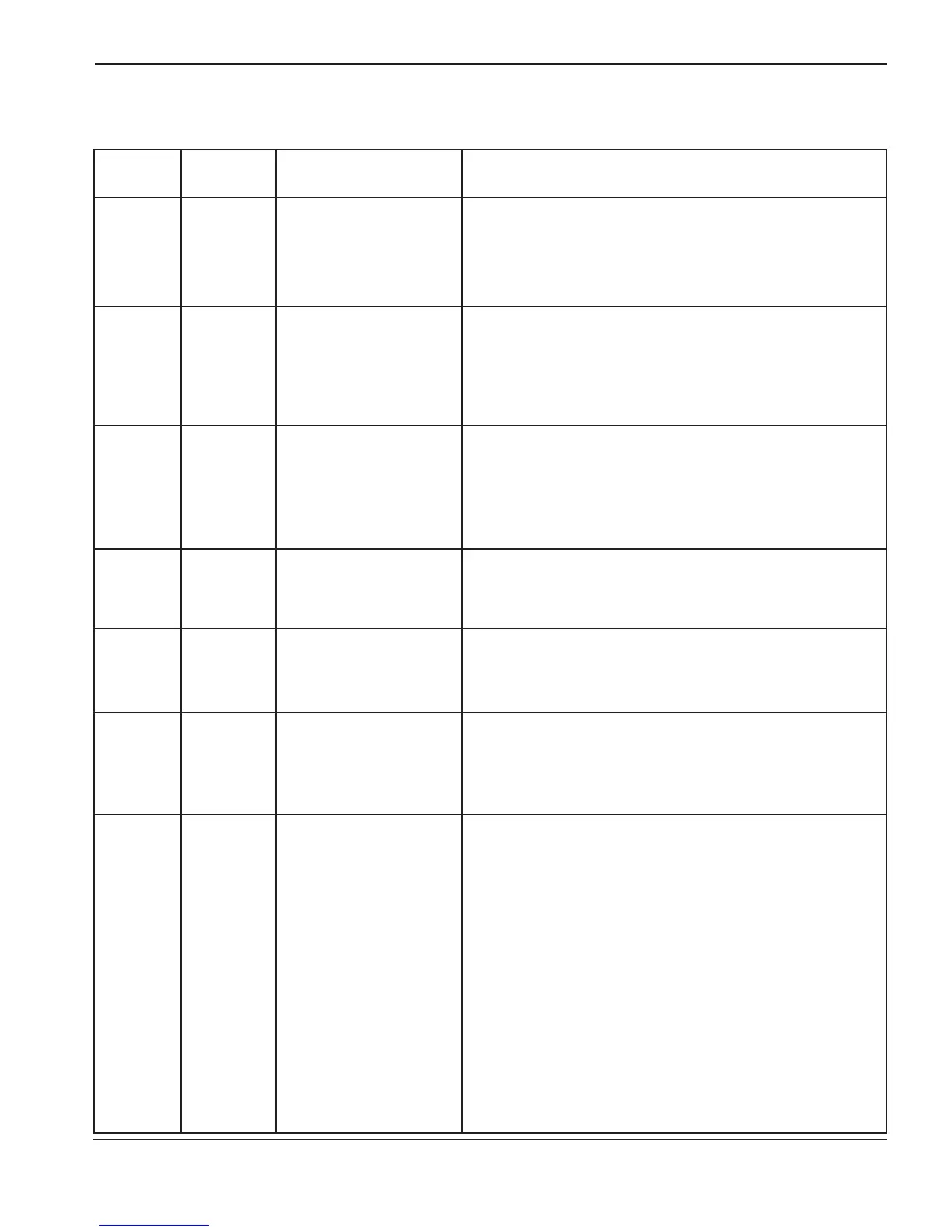

Error code troubleshooting – 7 of 10

Error code

number

Name Description Corrective action

104

High current

on CS2

A current greater than

35 amps has been

detected by

current sensor 2.

1. Verify that there is not a short on the I/O PCB, between the

work lead and the negative lead.

2. Remove fuse F4 and check for a short on Chopper B from

wire 38 to wire 39.

3. Verify fuse (F4).

105

Low current

on CS1

A current less than

10 amps has been

detected by

current sensor 1.

1. Verify the connections on CS1.

2. Verify that +/- 15 VDC is present at the CS1 connector.

3. Verify fuse (F3).

4. Verify that contactor CON1 is closing.

5. Remove fuse F3 and check the open circuit voltage (OCV)

on wire 38 and wire 39 at chopper A when CON1 closes.

106

Low current

on CS2

A current less than

10 amps has been

detected by

current sensor 2.

1. Verify the connections on CS2.

2. Verify that +/- 15 VDC is present at the CS2 connector.

3. Verify fuse (F4).

4. Verify that contactor CON1 is closing.

5. Remove fuse F4 and check the open circuit voltage (OCV)

on wire 38 and wire 39 at chopper B when CON1 closes.

108

Transfer at

power-up

The system has detected

current on the work lead

during power-up.

1. Verify that the electrical connections to current sensors CS1

And CS3 are correct and not damaged.

2. Replace PCB 3 if connections are correct and not

damaged.

109

Coolant flow

at power-up

“Coolant flow OK” signal

is active during power-up

and before pump motor

is activated.

1. Either coolant flow sensor was bypassed or the flow switch

is faulty.

111

Coolant

overtemp at

power-up

Coolant is indicating an

overtemp at power-up.

1. Verify that the coolant temperature sensor has not been

jumped out or the wires to the sensor are not shorted out in

the harness.

2. If not, the coolant temperature is over the set point and

needs time to cool to 70° C (158° F).

116

Watchdog

interlock

An error occurred with the

CAN communication

system.

1. Verify that cable number 5 (power supply-to-gas console

control cable) is not damaged and is properly connected to

PCB3 and the rear of the gas console.

2. Verify that cable number 6 (power supply-to-gas console

power cable) is not damaged and is properly connected

inside the power supply and to the rear of the gas console.

3a. (Manual gas console) Verify that D1 (+5 VDC) and D2

(+3.3 VDC) are illuminated on PCB2 inside the gas

console. These LEDs indicate power to PCB2.

3b. (Auto gas console) Verify that D17 (+5 VDC) and D18

(+3.3 VDC) are illuminated on PCB2 inside the gas

console. These LEDs indicate power to PCB2.

4. If power is present at PCB2 and PCB3 and both gas

console cables are good, then PCB2 or PCB3 has failed.

Use the CAN tester to verify which board needs to be

replaced.

6

Loading...

Loading...