INSTALLATION

3-24 HPR130 Manual Gas Instruction Manual

6

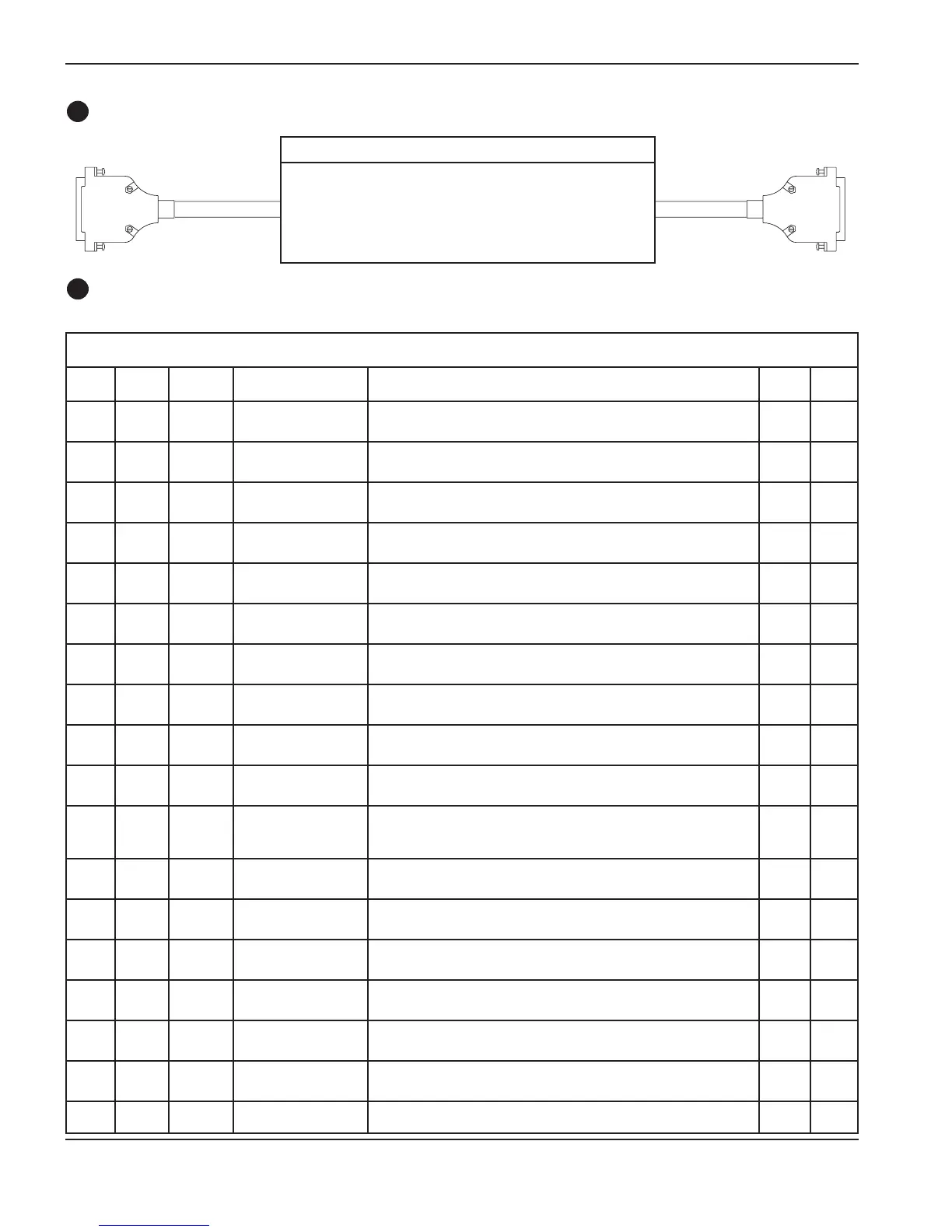

Wire Input/ Input/

color Pin # Output Signal name Function Output Notes

Black 1 Input Rx - RS-422 serial receiver Output

Red 20 Input Rx + RS-422 serial receiver Output

Black 2 Output Tx - RS-422 serial transmitter Input

Green 21 Output Tx + RS-422 serial transmitter Input

Black 3 RS-422 ground RS-422 serial ground

Blue 22 None Not used

Black 4 Output Motion 1 E (-) Notifies the CNC that an arc transfer has occurred and to begin Input 2 & 3

Yellow 23 Output Motion 1 C (+) machine motion once the CNC’s pierce delay has timed out. Input

Black 5 Output Error E (-) Notifies the CNC that an error has occurred. Input 2

Brown 24 Output Error C (+) Input

Black 6 Output Rampdown error E (-) Notifies the CNC that a rampdown error has occurred Input 2

Orange 25 Output Rampdown error C(+)

Red 7 Output Not ready E (-) Notifies the CNC that the plasma system is not ready to fire an arc Input 2

White 26 Output Not ready C (+)

Red 8 Output Motion 2 E (-) Notifies the CNC that an arc transfer has occurred and to begin Input 2 & 3

Green 27 Output Motion 2 C (+) machine motion once the CNC’s pierce delay has timed out. Input

Red 9 Output Motion 3 E (-) Notifies the CNC that an arc transfer has occurred and to begin Input 2 & 3

Blue 28 Output Motion 3 C (+) machine motion once the CNC’s pierce delay has timed out. Input

Red 10 Output Motion 4 E (-) Notifies the CNC that an arc transfer has occurred and to begin Input 2 & 3

Yellow 29 Output Motion 4 C (+) machine motion once the CNC’s pierce delay has timed out. Input

Red 11 None Not used

Brown 30 None Not used

Red 12 Input Corner - CNC Notifies the plasma system that a corner is approaching and to Output 1

Orange 31 Input Corner + reduce cut current (Cut current is CNC selectable or defaults to 50%. Output

of cut current)

Green 13 Input Pierce - CNC Notifies the plasma system to maintain the shield preflow until Output 1

White 32 Input Pierce + the CNC releases the signal.

Green 14 Input Hold - Not required without CommandTHC. CommandTHC requires signal Output 1

Blue 33 Input Hold + to preflow gases during IHS.

Green 15 Input Start - CNC initiates the plasma arc. Output 1

Yellow 34 Input Start + Output

Green 16 None Not used

Brown 35 None Not used

Green 17 None Not used

Orange 36 Power ground Ground

White 18 Power ground Ground

Black 37 CNC +24 VDC Available 24 VDC (200 milliamps maximum) See notes 4

19 CNC + 24 VDC Not connected

Power supply to CNC interface cable

Part no. Length Part no. Length

123210 3 m (10 ft) 123741 25 m (82 ft)

123211 4.5 m (15 ft) 123742 35 m (115 ft)

123022 7.5 m (25 ft) 123220 45 m (150 ft)

123214 10 m (35 ft) 123852 60 m (200 ft)

123023 15 m (50 ft) 123853 75 m (250 ft)

123851 20 m (65 ft)

Loading...

Loading...