INSTALLATION

3-42 HPR130 Manual Gas Instruction Manual

6

Gas requirements

The customer must furnish all gases and gas-supply regulators for the system. Use a high-quality, 2-stage pressure

regulator located within 3 m (10 ft) of the gas console. See gas regulators in this section for recommendations. See

Section 2 for gas and flow specifications.

Note: Oxygen, air and nitrogen are required for all systems. Nitrogen is used as a purge gas.

Caution: Gas supply pressures not within the specifications in Section 2 can cause

poor cut quality, poor consumable life and operational problems.

If the purity level of the gas is too low (or too high in the case of methane) or if

there are leaks in the supply hoses or connections,

• Cut speeds can decrease

• Cut quality can deteriorate

• Cutting thickness capability can decrease

• Parts life can shorten

Setting the supply regulators

1. Turn OFF the power to the system. Set all gas regulator pressures to 8.3 bar (120 psi).

2. Turn ON the power to the system.

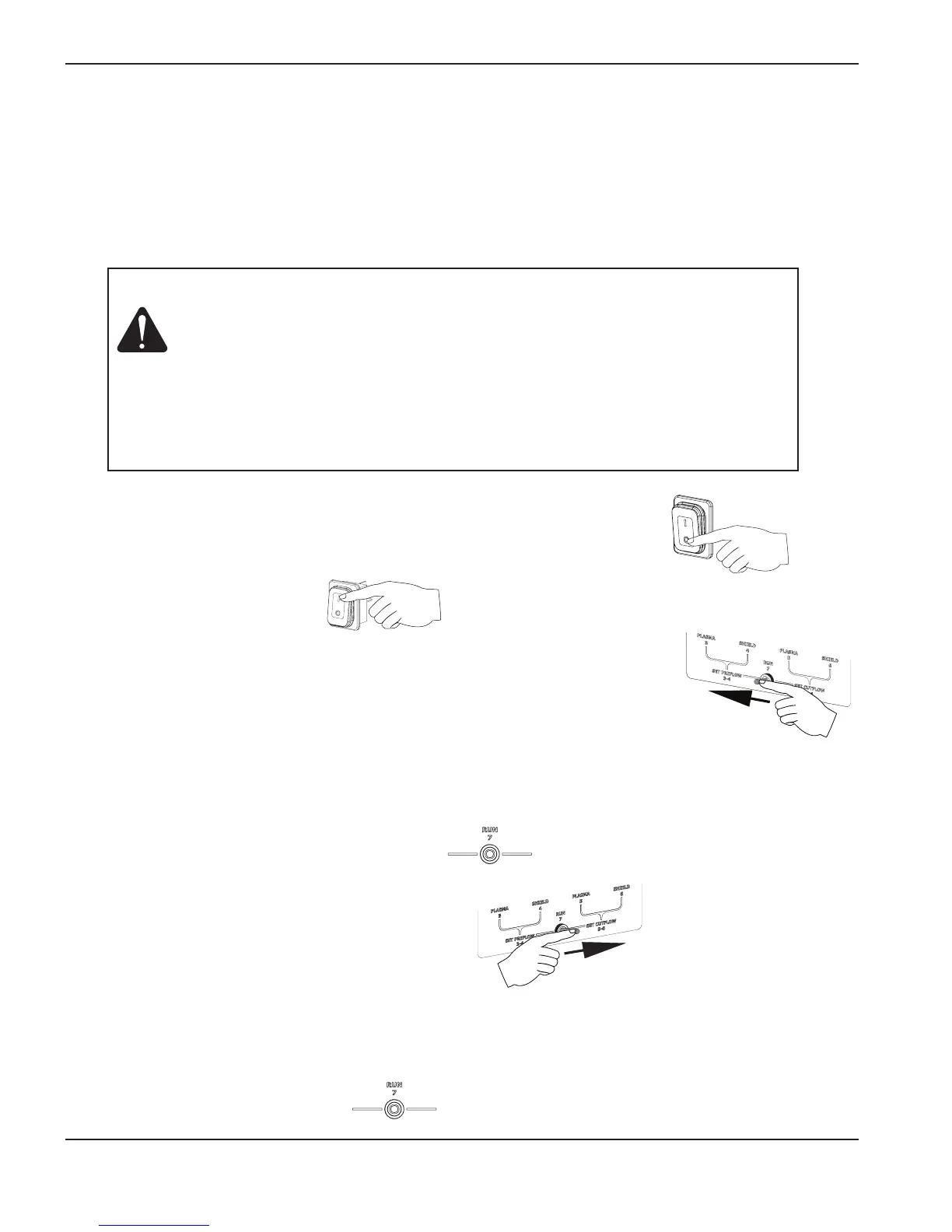

3. After the purge cycle stops, move switch (7) on the gas console to SET PREFLOW.

4. While gas is flowing adjust the supply regulator for the shield gas pressure to 8.3 bar

(120 psi).

5. Move switch (7) back to the RUN position (center).

6. Move switch (7) to the CUTFLOW position (right position).

7. While gas is flowing adjust the supply regulator for the plasma gas to 8.3 bar (120 psi).

8. Move switch (7) to the RUN position.

Loading...

Loading...