160 HyPrecision Predictive waterjet pump Operator Manual 810120

7 – Troubleshooting

Troubleshooting

Change the overstroke %

Overstroke % is the increased stroke rate that is permitted before an overstroke fault condition occurs.

Contact a Hypertherm Technical Service Associate for information and support.

Other stroking problems

The intensifier is not enabled.

Make sure that the intensifier is enabled. Refer to Intensifier Control on page 223.

The cutting head is turned off.

Turn ON the cutting head.

A proximity switch has failed.

An indicator spring is broken or damaged.

An indicator pin is stuck.

If the amber lights are on at the same time, a proximity switch might have failed, an indicator spring might be

broken, or an indicator pin might be stuck. Examine all parts to find the cause of the fault.

A proximity switch cord has failed.

Examine the cords on the proximity switches for damage.

A proximity switch has failed.

Interchange the proximity switches (but not the wires). If the intensifier stalls on the opposite end, replace

the proximity switches.

Examine the indicator pin for burrs. The pins should move easily to the bottom of the bore.

Make sure that the indicator pin springs are not broken and that they are the same length.

A shift pin is damaged.

While the pump is in cooling mode, push on the shift pin on the stalled side. The shift pin is found at the ends

of the coil on the pilot valve.

If the intensifier strokes to other side, the problem is electrical.

If the intensifier does not move, the problem is mechanical.

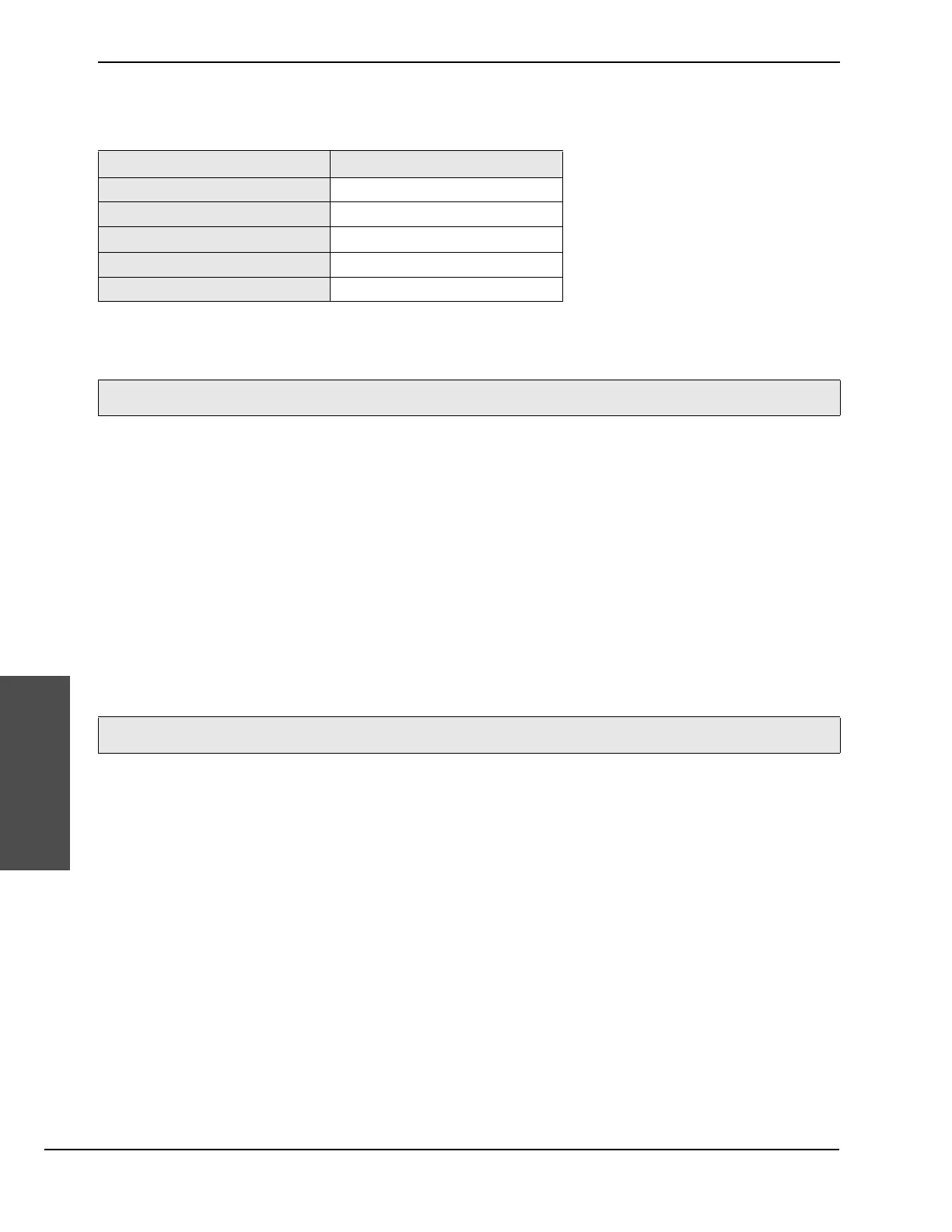

HyPrecision pump model Maximum strokes/minute

Default overstroke percentage = 5%

Maximum overstroke percentage = 20%

P-15

26

P-30

52

P-50 and P-50S

84

P-60S

90

P-75S

100

The intensifier does not stroke to either side

The intensifier strokes to 1 side and then stalls on the same side

Loading...

Loading...