MAXPRO200 Instruction Manual 807700 Revision 1 35

Specifications

Cooling system

The cooling system uses a liquid-to-air cooled heat exchanger and a pump to reduce the temperature of the coolant. The

coolant cools the chopper, torch lead and torch. The cooling system also contains flow and temperature sensors that

verify the cooling system is working properly.

System gas requirements

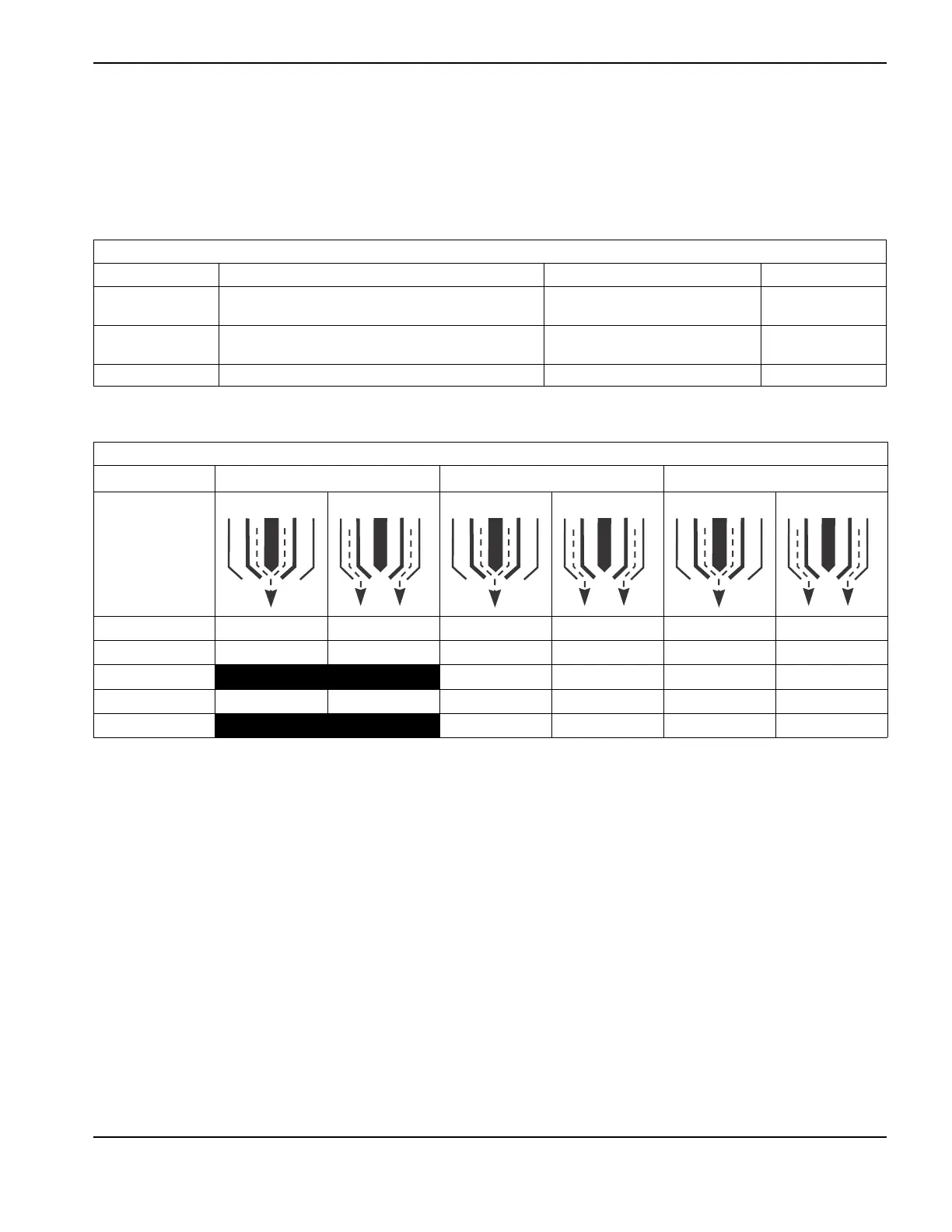

Gas quality and pressure requirements

Gases Quality Pressure +/- 10% Flow rate

O

2

oxygen 99.5% pure (liquid gas recommended)

Clean, dry, and oil free

621 kPa / 6.2 bar / 90 psi 3400 l/h 120 scfh

N

2

nitrogen 99.9% pure (liquid gas recommended)

Clean, dry, and oil free

621 kPa / 6.2 bar / 90 psi 11330 l/h 400 scfh

Air Clean, dry, and oil free (ISO 8573-1 class 1.4.2) 621 kPa / 6.2 bar / 90 psi 11330 l/h 400 scfh

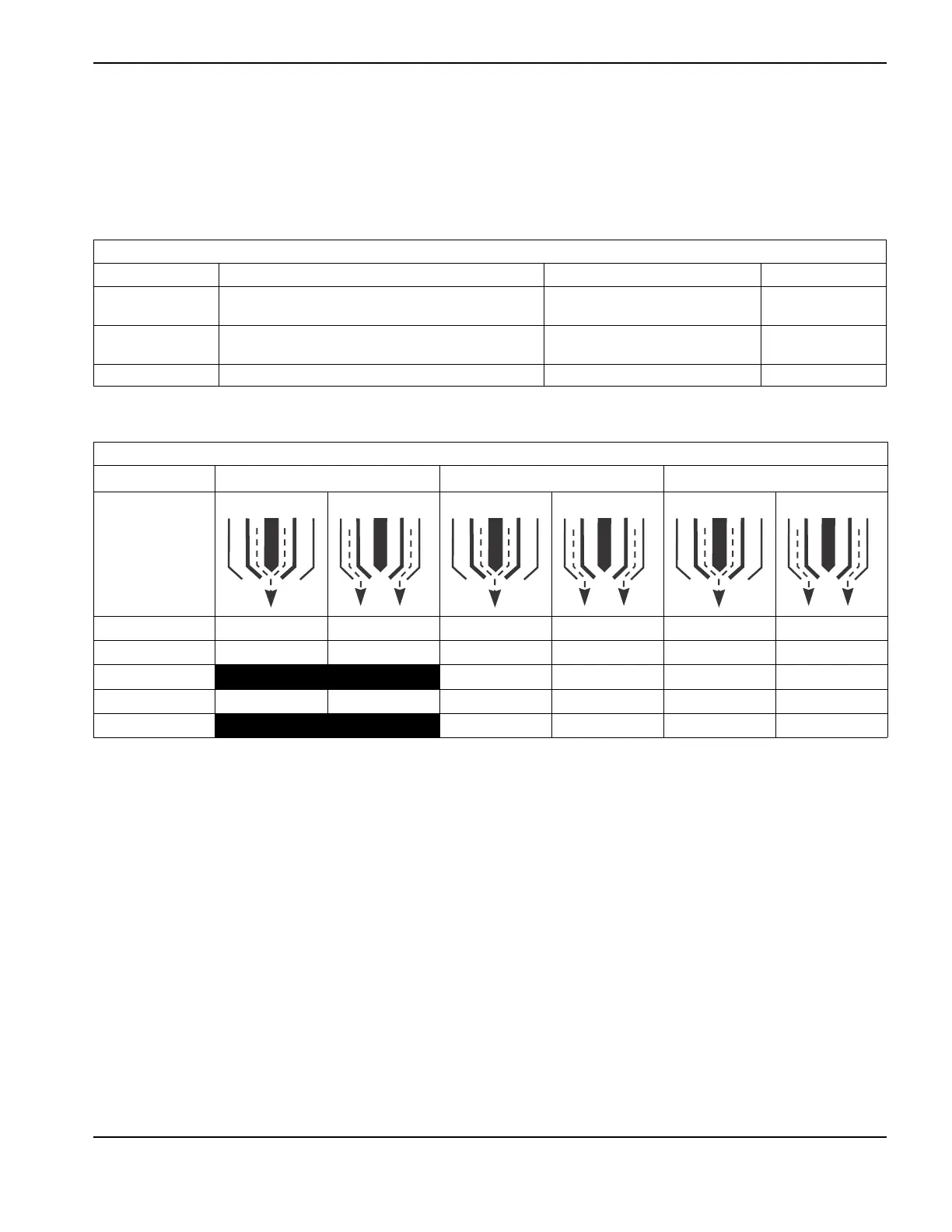

Gases by process

Mild steel Stainless steel Aluminum

Amperage

Plasma gas Shield gas Plasma gas Shield gas Plasma gas Shield gas

Cutting 50 A Air or O

2

Air Air Air Air Air

Cutting 130 A Air or O

2

Air Air Air Air Air

Cutting 130 A N

2

N

2

N

2

N

2

Cutting 200 A Air or O

2

Air Air Air Air Air

Cutting 200 A N

2

N

2

N

2

N

2

Loading...

Loading...