SETUP

powermax1650 Operator Manual 3-15

2

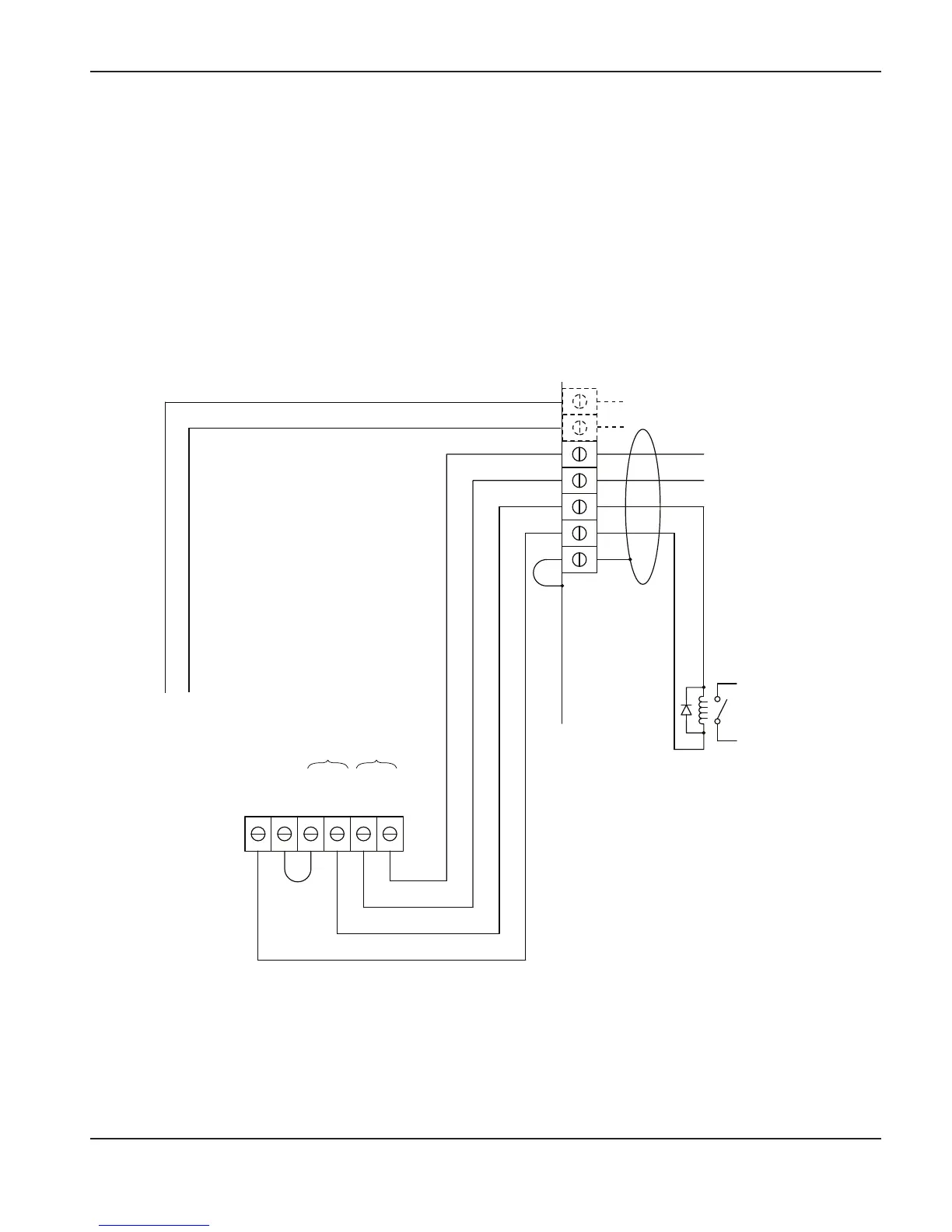

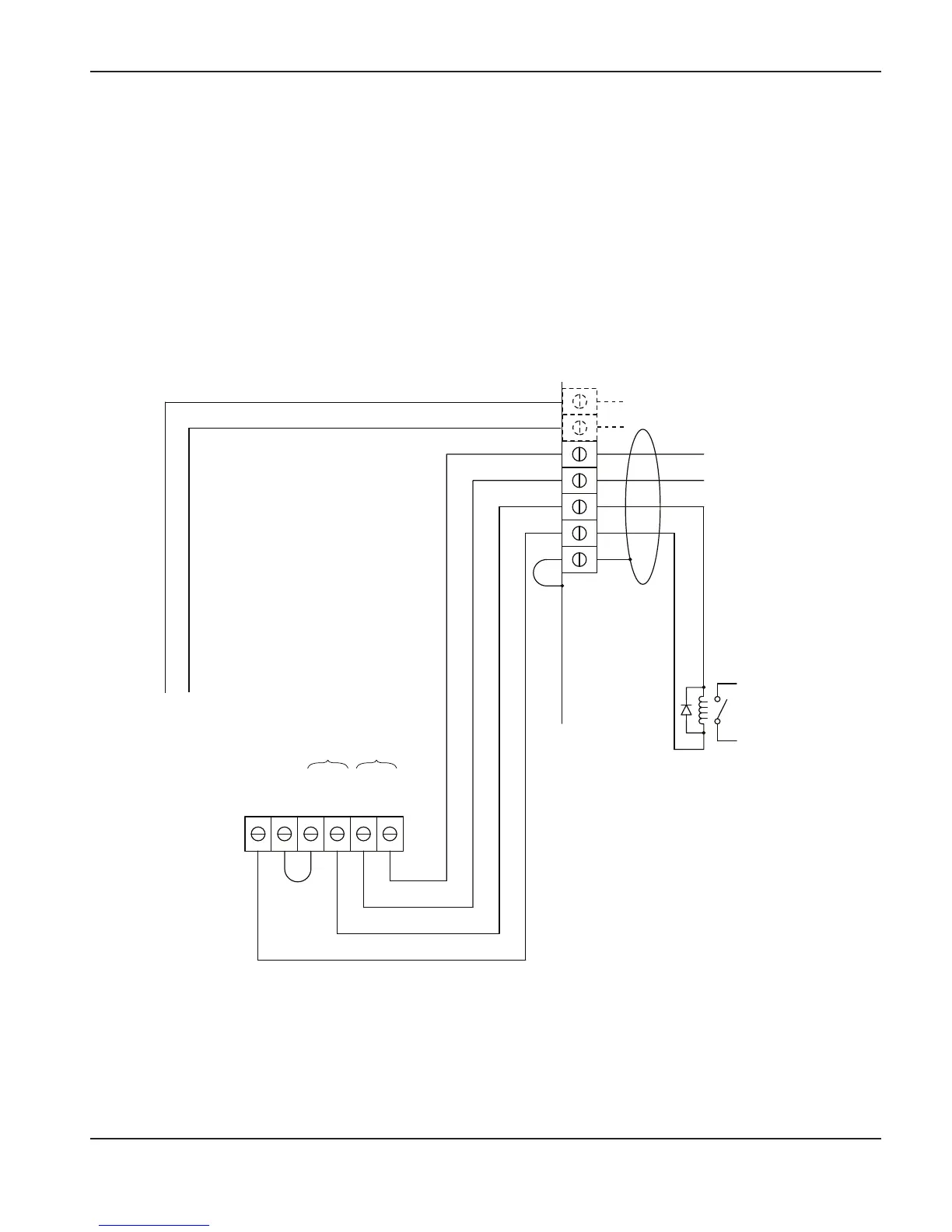

Changing XFER (start machine motion) from dry contact closure to

voltage signal

24 VDC (chassis ground reference) at 100ma max is available at J19 on the powerboard to drive

an isolated/floating device such as a 24 VDC relay coil (240 ohms or greater) or a typical industrial

isolated input module (which has an opto-coupler built-in). Shown below are typical connections

for a high-side drive arrangement.

Driving a relay coil

Notes:

1. Customer supplied 24 VDC

relay coil > 240 ohms.

2. Must use suppression diode

(1A, 100V) such as IN4002

through IN4004 type across

coil.

3. Pins 5 and 6 are used only on

systems that include the

PowermaxEDGE cable with

voltage divider.

Move the black (BLK) wire

to ground (GND) and add

a jumper wire as shown.

5

V-div –

6

V-div +

4

3

14

12

13

Shield

J16

J15

J19

GND

24VDC

BLK

YEL

RED

WHT

XFER START

Start

Signal

BLK

Loading...

Loading...