Powermax30 XP Service Manual 808150 Revision 0 53

4–Operation

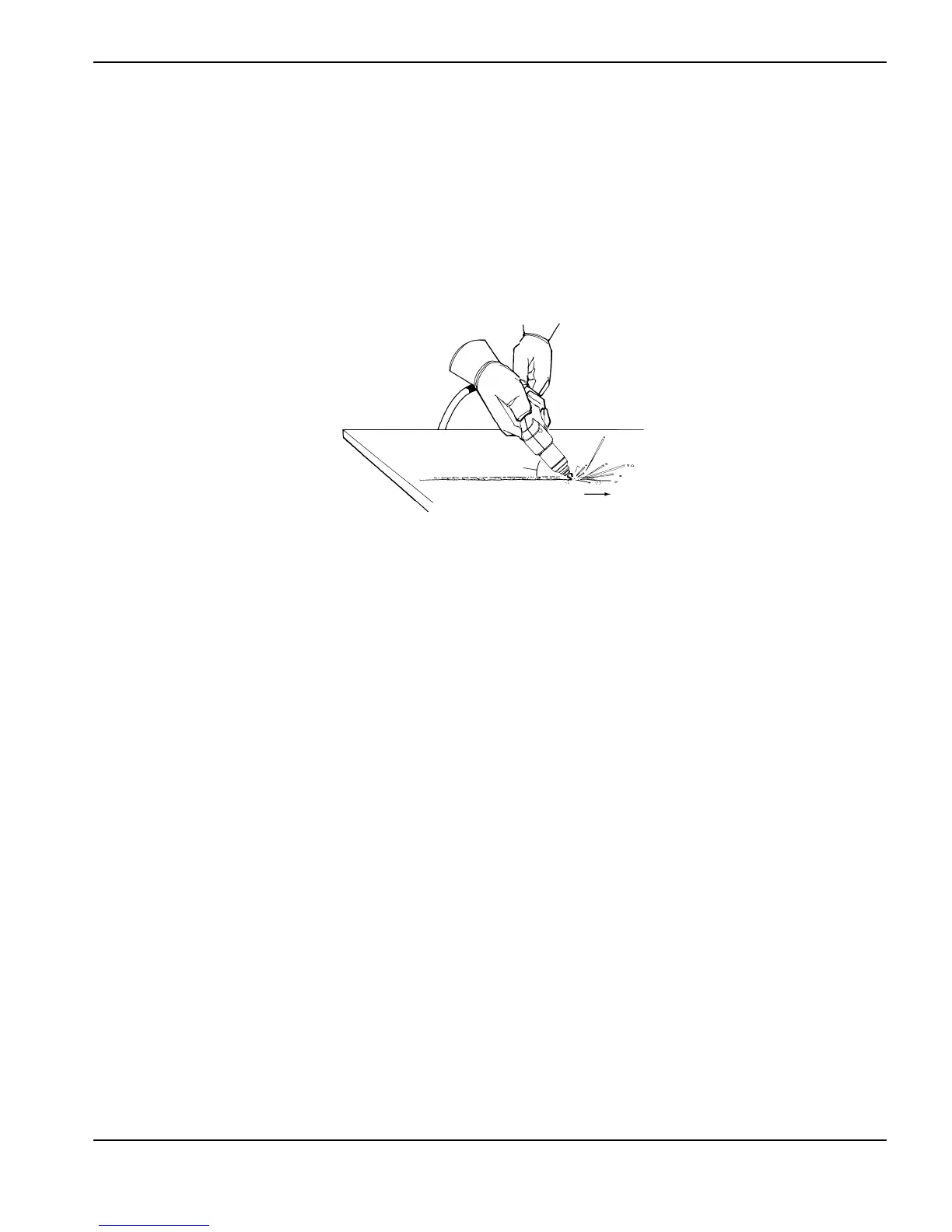

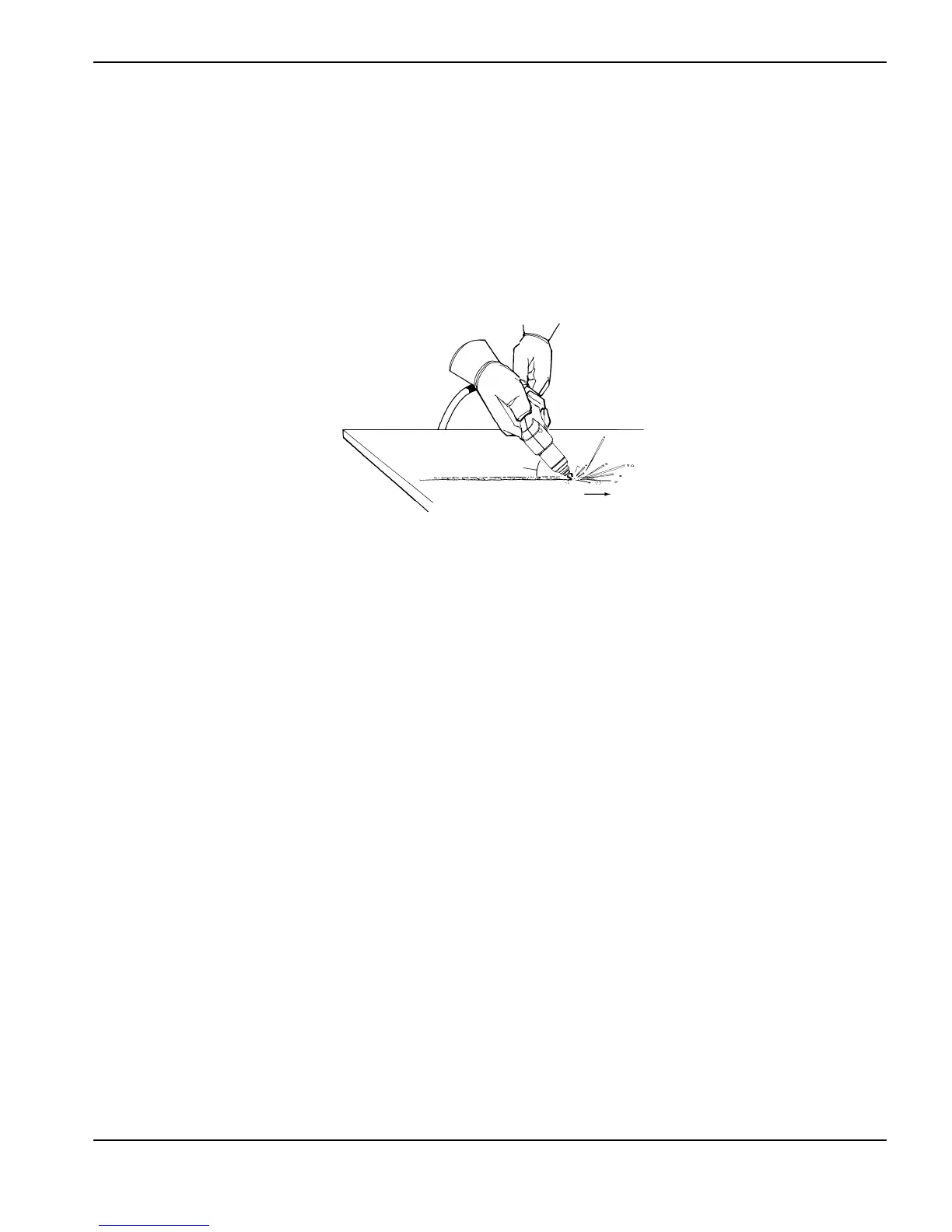

3. Maintain an approximate 45° angle to the workpiece as you feed into the gouge.

Push the plasma arc in the direction of the gouge you want to create. Keep a small distance between the torch tip

and the molten metal to avoid reducing consumable life or damaging the torch.

You can vary the gouge profile by varying the:

Speed of the torch over the workpiece

Torch-to-work standoff distance

Angle of the torch to the workpiece

System’s current output

Varying the gouge profile

Follow these recommendations to change the gouge profile as needed:

Increasing the speed of the torch will decrease width and decrease depth.

Decreasing the speed of the torch will increase width and increase depth.

Increasing the standoff of the torch will increase width and decrease depth.

Decreasing the standoff of the torch will decrease width and increase depth.

Increasing the angle of the torch (more vertical) will decrease width and increase depth.

Decreasing the angle of the torch (less vertical) will increase width and decrease depth.

Increasing the current of the power supply will increase width and increase depth.

Decreasing the current of the power supply will decrease width and decrease depth.

Loading...

Loading...