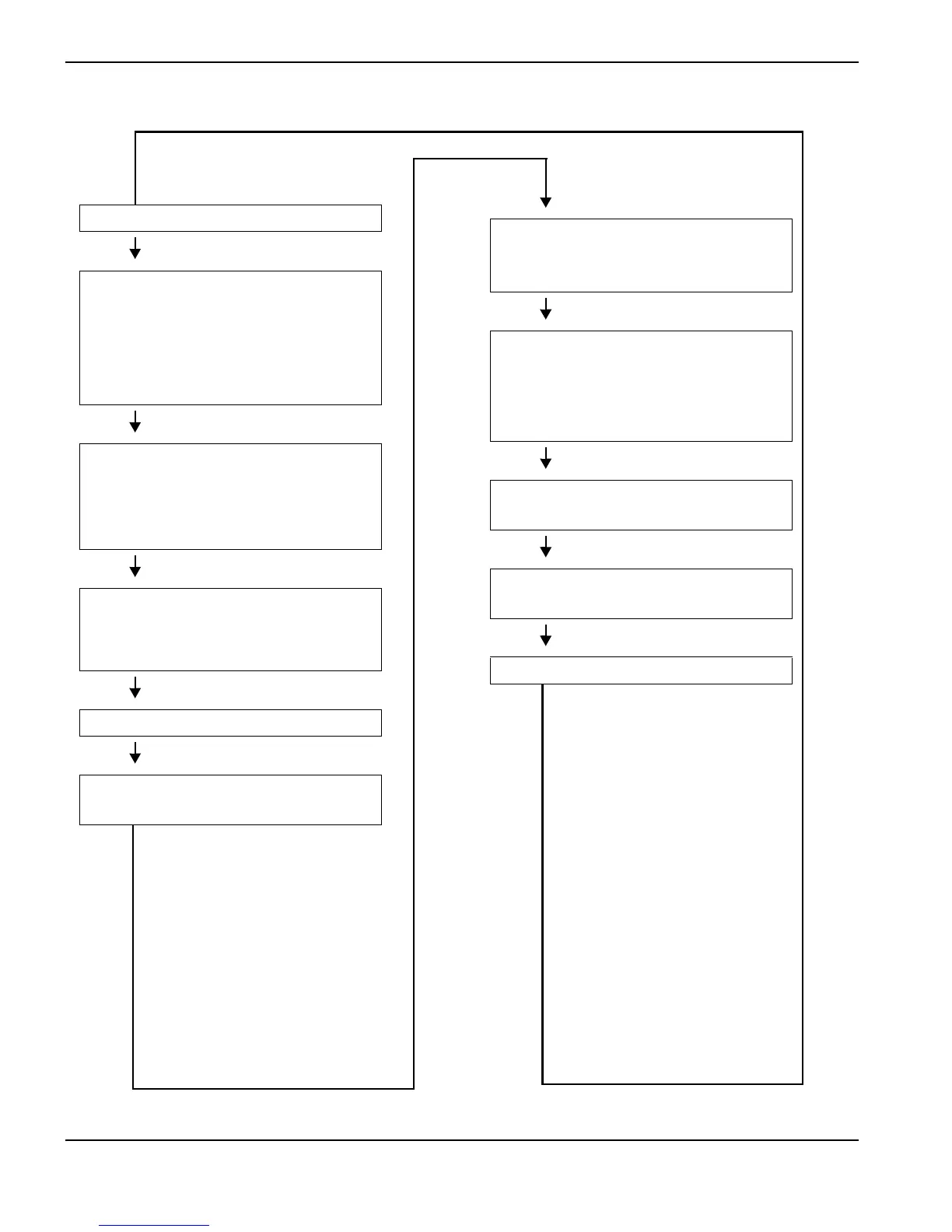

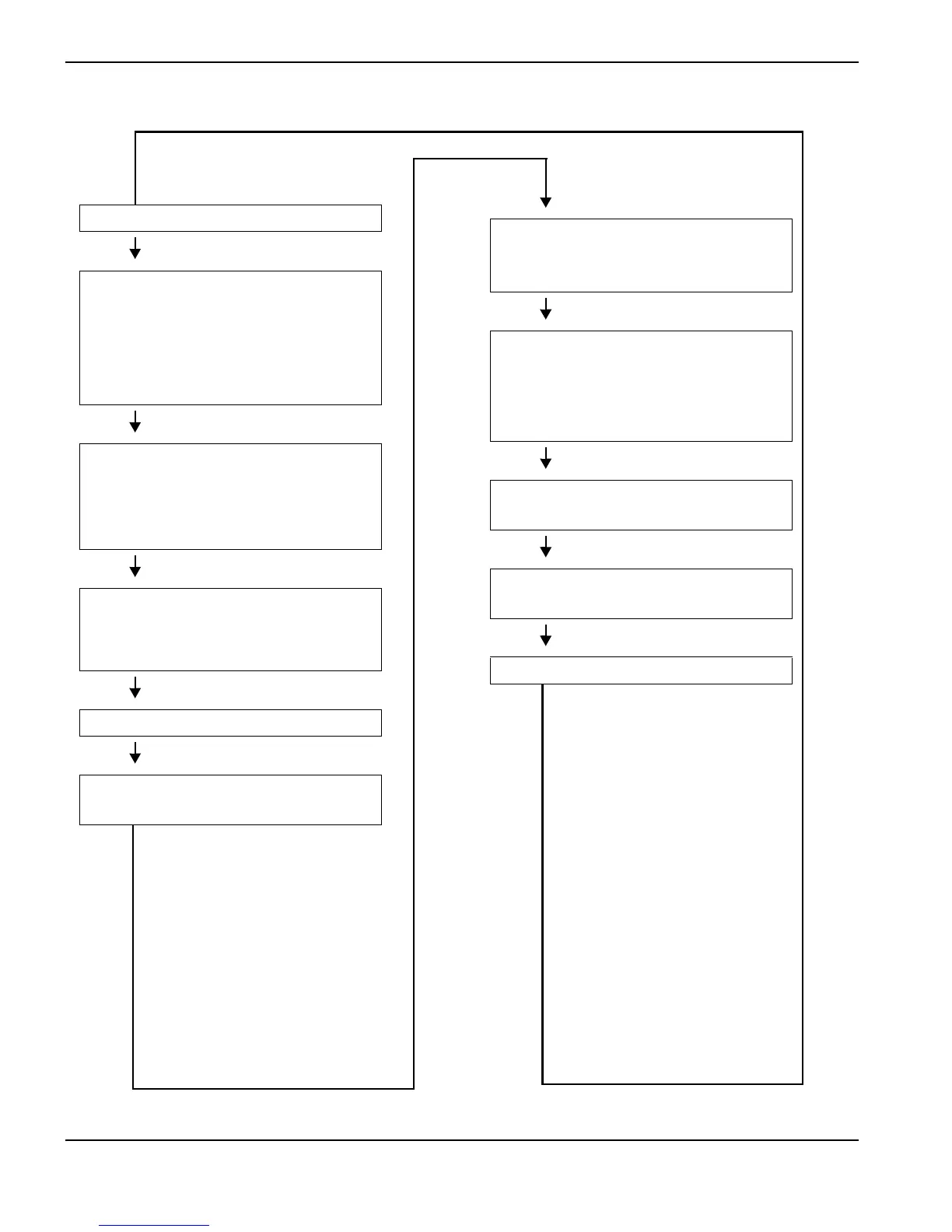

Power OFF (O)

• Connect the gas supply to the gas fitting

on the power supply.

• Connect the work lead to the workpiece.

• Apply power at the line-voltage

disconnect box.

• Set the power switch (S1) to ON (I).

• The green power-ON LED illuminates,

indicating the system is ready for

operation.

• All the fault LEDs should be extinguished.

(See Troubleshooting guide on page 63.)

• Set the amperage adjustment knob to the

desired output current (between 15 A and

30 A) based on the input voltage and

circuit size.

• The power circuits are ready.

• Position the torch on the workpiece.

• Pull the plasma start trigger on the torch.

• The gas solenoid valve (V1) opens.

• The gas flow starts.

• The cutting arc starts.

• Drag the torch lightly across the

workpiece to make a cut.

• The workpiece drops after the cut.

• Release the plasma start trigger on the

torch.

• The arc extinguishes.

• Gas postflow continues for 20 seconds.

• The gas solenoid valve (V1) closes.

• The gas flow stops.

• Set the power switch (S1) to OFF (O).

Loading...

Loading...