Table 36. Gas and particulate exposure

Contaminate Requirement

Gaseous contamination Severity level G1 as per ANSI/ISA 71.04-1985

1

, which states that the reactivity rate of copper coupons shall be less than 300 Angstroms

per month (Å/month, ≈ 0.0039 µg/cm² - hour weight gain)

2

. In addition, the reactivity rate of silver coupons shall be less than 300

Å/month (≈ 0.0035 µg/cm² - hour weight gain)

3

. The reactive monitoring of gaseous corrosivity should be conducted approximately 5

cm (2 in.) in front of the rack on the air inlet side at one-quarter and three-quarter frame height off the floor or where the air velocity is

much higher.

Particulate contamination Data centers must meet the cleanliness level of ISO 14644-1 class 8. For data centers without airside economizer, the ISO 14644-1 class 8

cleanliness might be met simply by the choice of the following filtration:

v The room air might be continuously filtered with MERV 8 filters.

v Air entering a data center might be filtered with MERV 11 or preferably MERV 13 filters.

For data centers with airside economizers, the choice of filters to achieve ISO class 8 cleanliness depends on the specific conditions

present at that data center.

The deliquescent relative humidity of the particulate contamination should be more than 60% RH.3

4

.

Data centers must be free of zinc whiskers

5

.

Notes:

1. ANSI/ISA-S71.04. 1985. Environmental conditions for process measurement and control systems: Airborne contaminants, Instrument Society of America, Research Triangle Park,

NC, 1985.

2. The derivation of the equivalence between the rate of copper corrosion product thickness growth in Å/month and the rate of weight gain assumes that Cu

2

S and Cu

2

O

grow in equal proportions.

3. The derivation of the equivalence between the rate of silver corrosion product thickness growth in Å/month and the rate of weight gain assumes that Ag

2

S is the only

corrosion product.

4. The deliquescent relative humidity of particulate contamination is the relative humidity at which the dust absorbs enough water to become wet and promote ionic

conduction.

5. Surface debris is randomly collected from 10 areas of the data center on a 1.5 cm diameter disk of sticky electrically conductive tape on a metal stub. If examination of the

sticky tape in a scanning electron microscope reveals no zinc whiskers, the data center is considered free of zinc whiskers.

Acoustical specifications

Several conditions must be in place to accommodate the acoustical specifications of

the TS4500 tape library. This topic provides a general statement about the

acoustical specifications. (For acoustical specifications by frame model, refer to the

“Acoustical specifications for models L25, D25, L55, and D55” topic.)

When the TS4500 tape library is both operating and idling, the following

conditions apply:

v Power is on.

v All air-moving devices are operating.

v Tape cartridges are loaded in all drives.

When the library is operating the cartridge accessor loads, unloads, or moves tape

cartridges. When the library is idling the accessor does not move.

The TS4500 tape library is a Category 1 product as defined in C-S 1-1710-006.

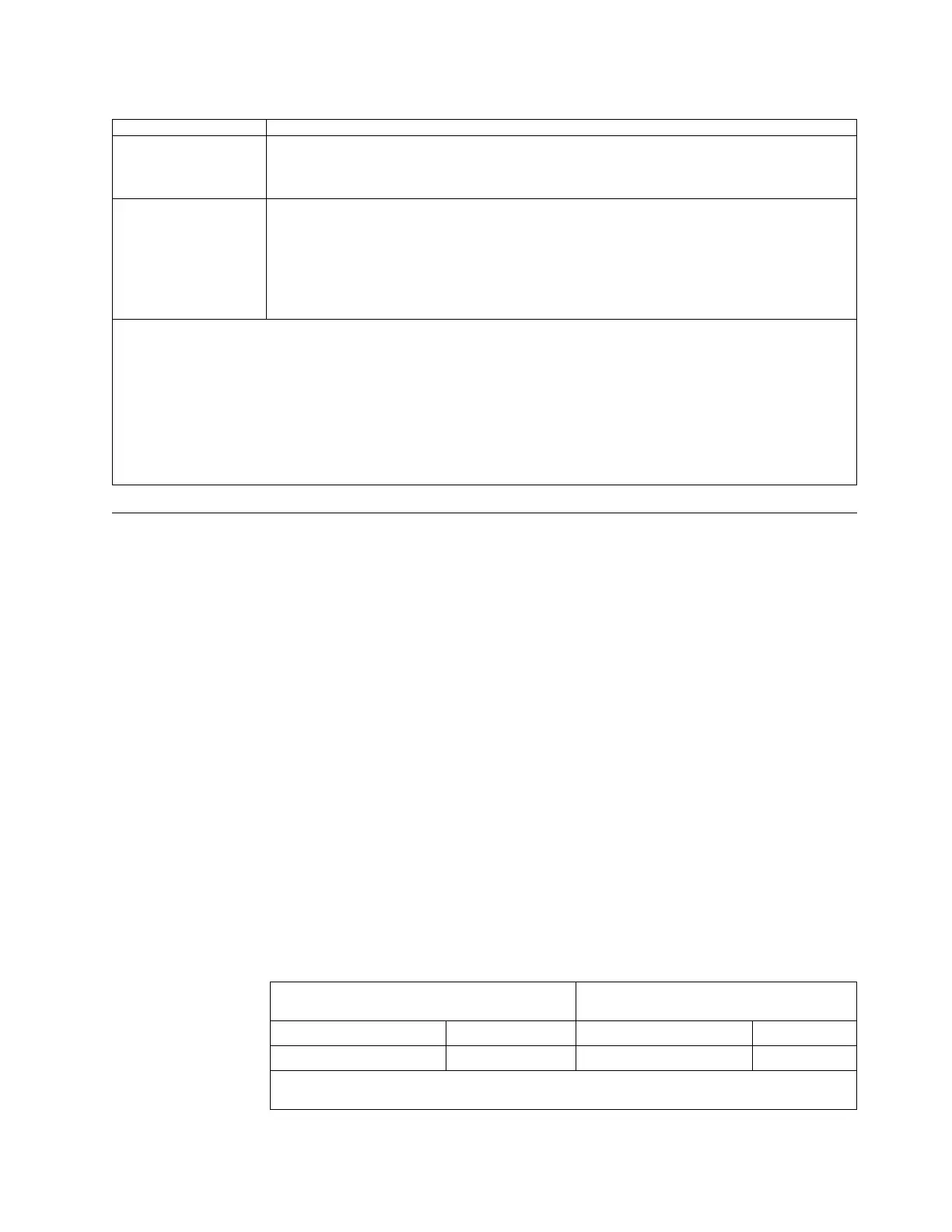

Acoustical specifications for models L25, D25, L55, and D55

Use this table to view the acoustical specifications and noise emission values for

Models L25, D25, L55, and D55 of the TS4500 tape library.

Table 37. Noise emission values for the TS4500 tape library models L25, D25, L55, and

D55

Declared Sound Power Level L

WAd

Mean A-weighted Sound Pressure Level

at the 1 m (Bystander) Positions <L

pA

>

m

Operating (bels) Idling (bels) Operating (dB) Idling (dB)

7.5 B 7.4 B 54 dB 51 dB

All measurements are in accordance with ANSI S12.10, and conform with ISO 9296.

Chapter 2. Planning 87

Loading...

Loading...