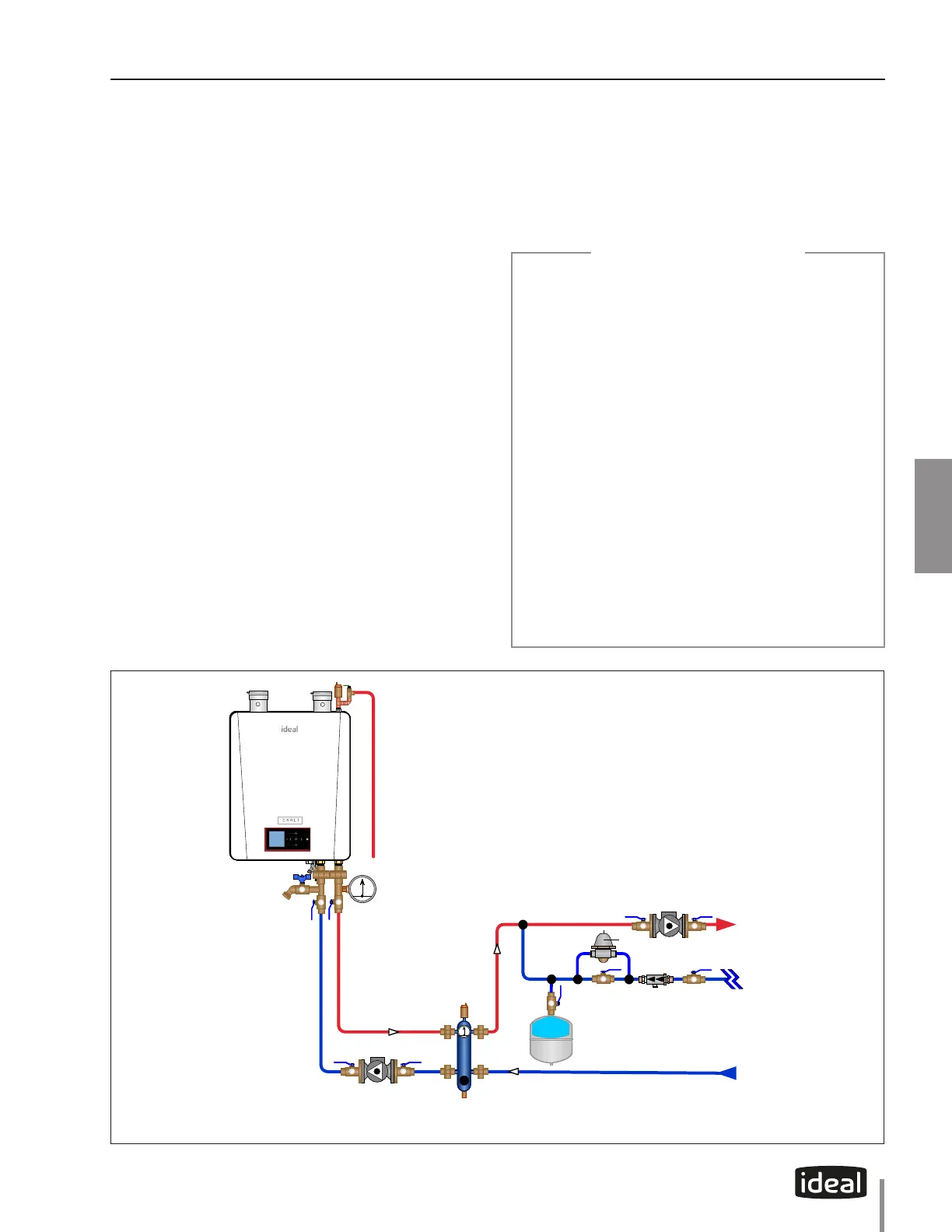

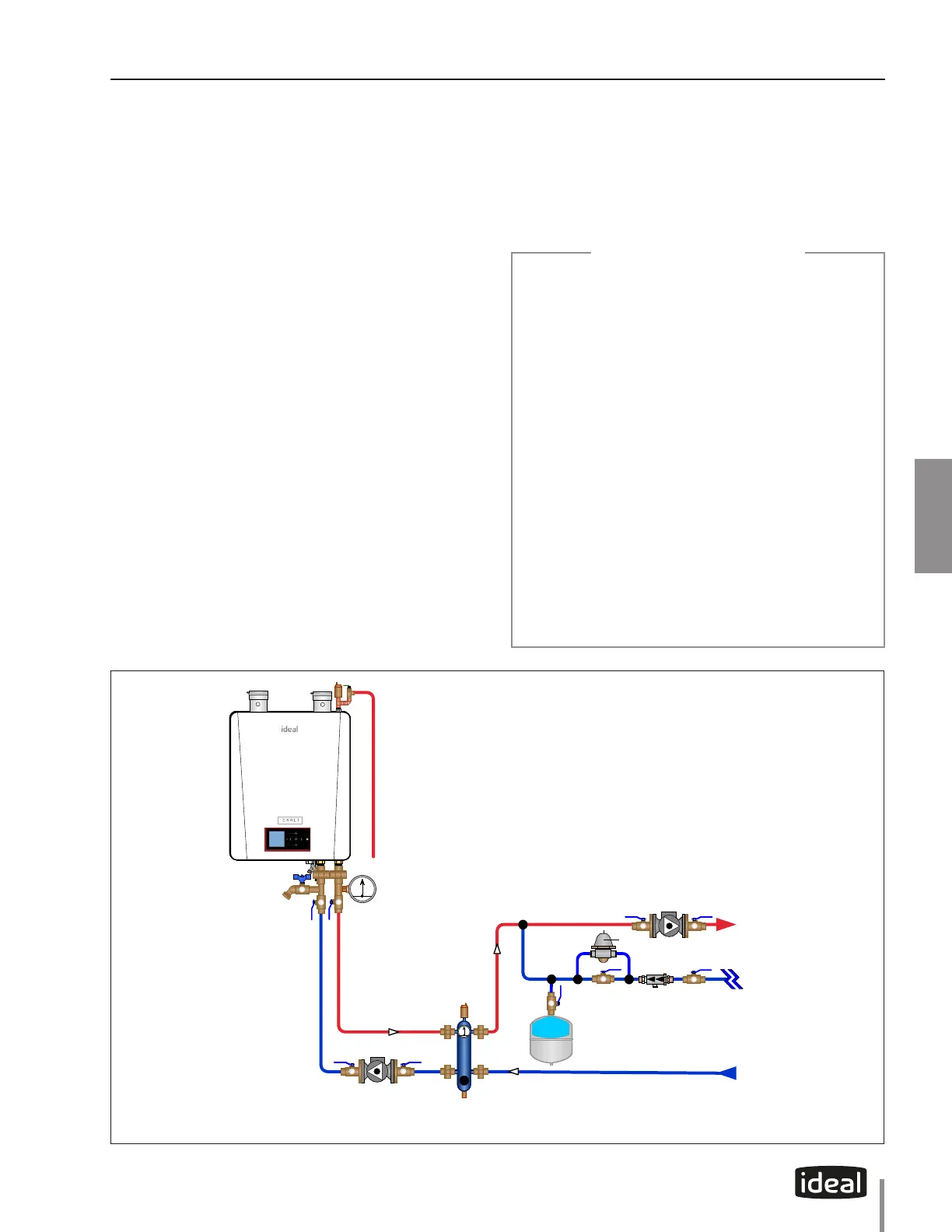

Fig. 8 - EXALT Solo Near Boiler Piping - Hydraulic Separator

17

CHAPTER 4

CHAPTER 4 - BOILER PIPING

4.5. Additional Limit Control

If a separate Low Water Cut O (LWCO) is required by

the local jurisdiction or when the boiler is installed

above the system piping, the following guidelines must

be followed:

• The LWCO must be designed for water installations,

electrode probe-type is recommended.

• The LWCO must be installed in a tee connection on

the boiler supply piping above the boiler.

• Wiring of the LWCO to the EXALT is done directly

onto the low voltage terminal strip. Reference

Fig. 30 on page 46 for available external limit

(manual or auto reset) terminals.

If the installation is to comply with ASME or Canadian

requirements, an additional high temperature limit may

be required. Consult local code requirements to determine

compliance. The limit should be installed as follows:

• Install the limit in the boiler supply piping between

the boiler and any isolation valve.

• Consult heat exchanger for maximum temperature

set point.

• For wiring of the limit, reference Fig. 30 on page 46.

Wire the limit to the manual reset terminals on the

low voltage terminal strip. An open manual reset

limit will require a manual reset of the control.

4.6. Backflow Preventer

• Use a backow preventer valve in the make-up

water supply to the unit as required by local codes.

4.7. EXALT Solo Boiler System Piping

• It is recommended on all piping app-

lications to utilize a primary/secondary

piping arrangement as a means to provide

freeze protection of the boiler, which is

an integral function of the boiler control.

Maintain at least the minimum boiler flow

rate shown in the Graphs of Chapter 19

on page 101. For other piping

arrangements, contact Ideal Technical

Support or consult other approved/

recognized design arrangements.

• On piping applications utilizing a single

zone or other recognized piping design

arrangements, it is recommended that

the installer uses flow/check valves with

weighted seats at or near the EXALT Solo to

prevent gravity circulation.

BEST PRACTICEBEST PRACTICE

Cold

Water

Fill

T P

T P

System

Supply

System

Return

Cold

Water

Fill

System

Return

System

Supply

Loading...

Loading...