CALIBRATION

The dryer is supplied factory set and therefore requires no further

calibration.

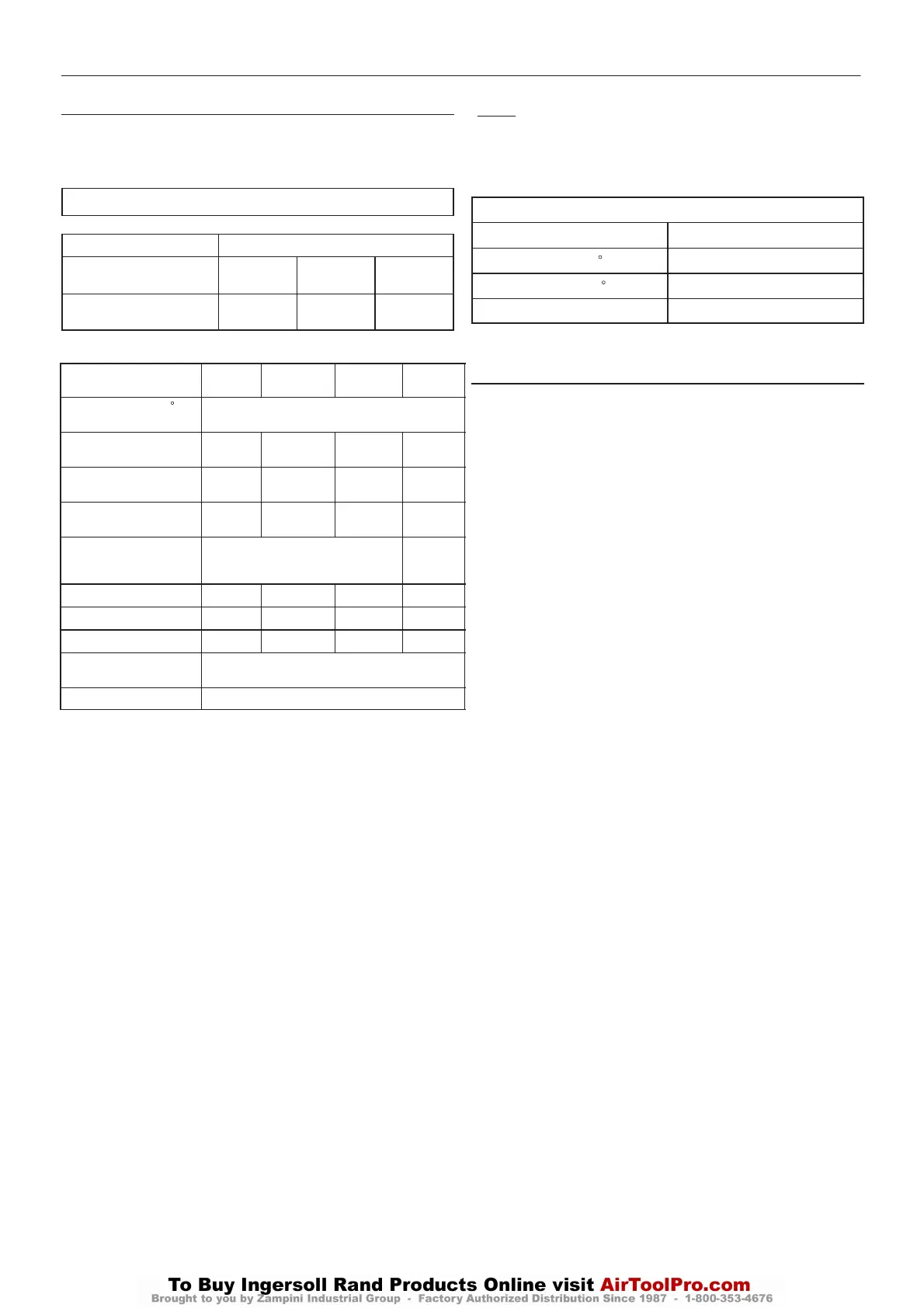

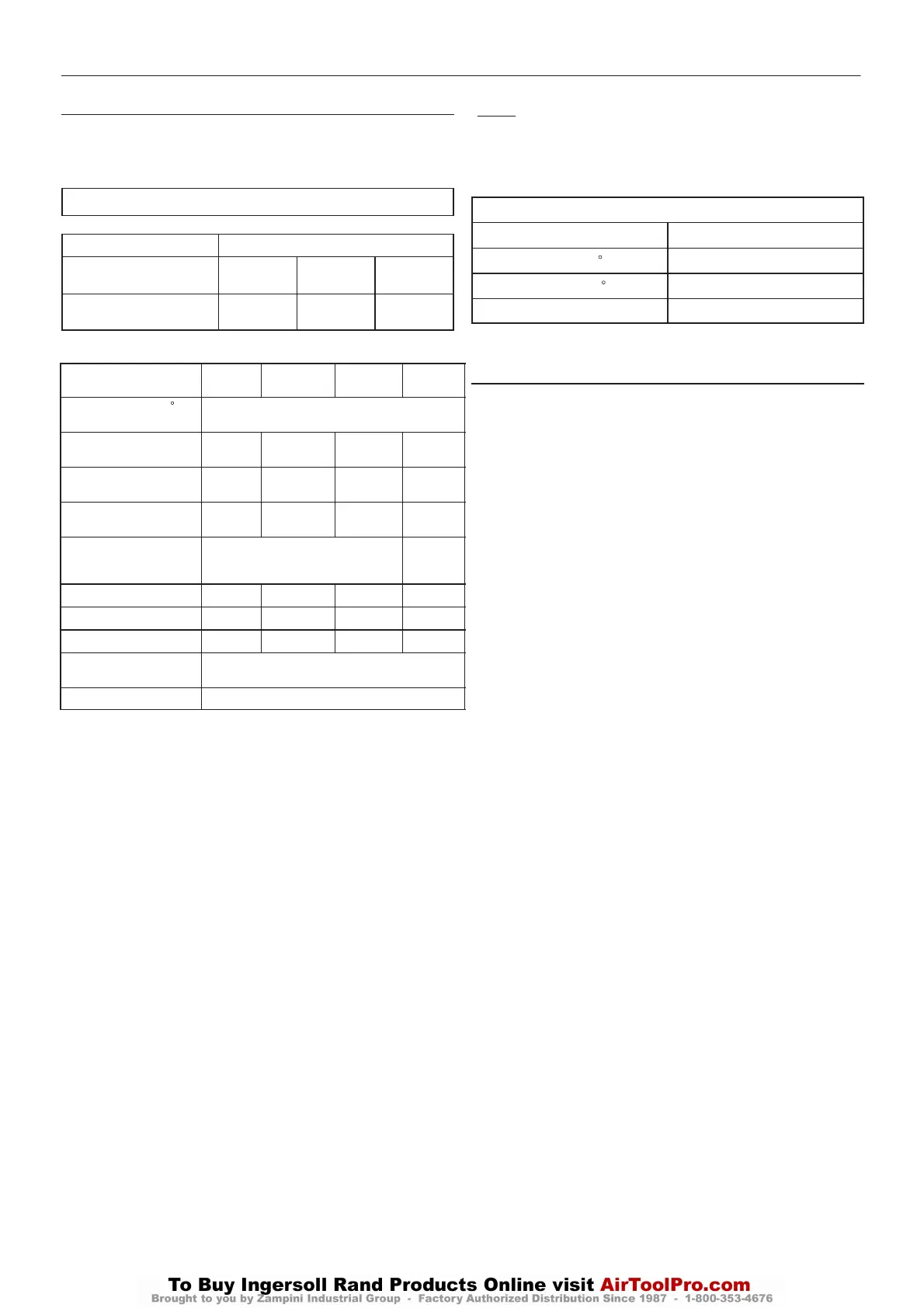

ENGINEERING DATA

Compressor

UP6 15 - 30

Maximum operating

pressure psig (bar)

125

(8.62)

150

(10.34)

200

(13.79)

Factory set reload

pressure psig (bar)

110

(7.58)

135

(9.31)

185

(12.76)

Model

UP6 20

UP6 25

UP6 30UP6 15

Pressure Dew Point ( F)

(see note 3. below)

38

Base–Mounted Dryer

Package Weight (lb)

1411

1451

1537

120 Gallon Tank Dryer

Package Weight (lb)

1735 1775 1861

240 Gallon Tank Dryer

Package Weight (lb)

2004 2044 2130

Electrical Supply

(+/– 10%) (AC)

(see note 2. below)

115V / 1ph / 60Hz

L.R.A. Current (Amps)

45.0 48.8 48.8

F.L.A. Current (Amps)

9.6 12.3 12.3

Total Installed Power (kW)

0.96

1367

1691

1960

45.0

9.6

0.96 1.19 1.19

Electrical Protection Class

(Std.)

NEMA 1 (IP20)

Refrigerant Type

134a

Notes:

1. Electrical data refers to dryer only.

2. The dryer requires a separate power supply from the compressor

drive.

3. Rated at:

Working Pressure (psig)

100

Inlet Air Temperature ( F)

100

Ambient Temperature ( F)

100

Relative Humidity (%)

100

Notes on the use of the Schrader non–return valve.

ATTENTION

1. This unit is equipped with refrigerant as for quantity and kind clearly

shown in operating manual and with identification label.

2. Any ordinary test and / or refrigerant recharge by means of

connections can take place only after refrigerant evacuation. The

evacuation must be proportional to dimensions and length of the

connections used. The use of the valve can be justified only when the

dryer is not in working order.

3. During the unit guarantee period, the Schrader valve can be used by

authorized staff only, otherwise any damage caused by a wrong

refrigerant recharge will invalidate warranty.

39

DRYER OPTION

http:/air.ingersollrand.com

UP6 15, UP6 20, UP6 25, UP6 30

Loading...

Loading...