- 164 -

In contrast, the smaller proportional gain KP is, the greater integration time

Ki will be, and the smaller derivative time KD is, the lower response will be.

Response too slowly can easily lead to inefficient and products unstable.

7.3 Servo oil pump optional parts prototyping

Flow is Q(L/min),system pressure is P1(kgf/cm2),motor or oil pump

manimum rotation speed is Vmax(rpm).

7.3.1 Oil pump prototyping

Oil pumps pressure selection:

Oil pumps rated pressure should be greater than system pressure P1

(kgf/cm

2

).

Oil pump displacement selection:

Oil pump displacement per revolution l(ml/rev)=Q(L/min)×1000(ml/L)

/ Vmax(rpm)

Oil pump type selection:

Please follow the instructions below corresponding to pump type selection

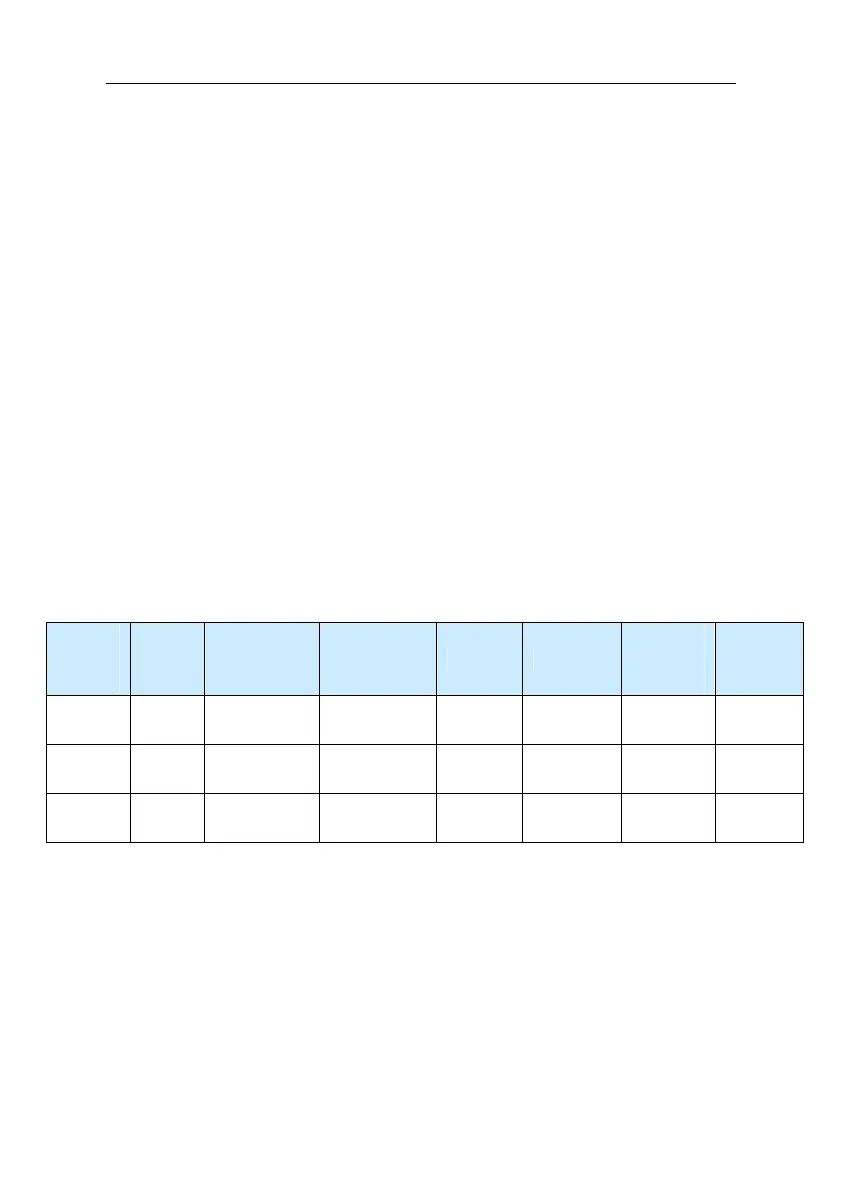

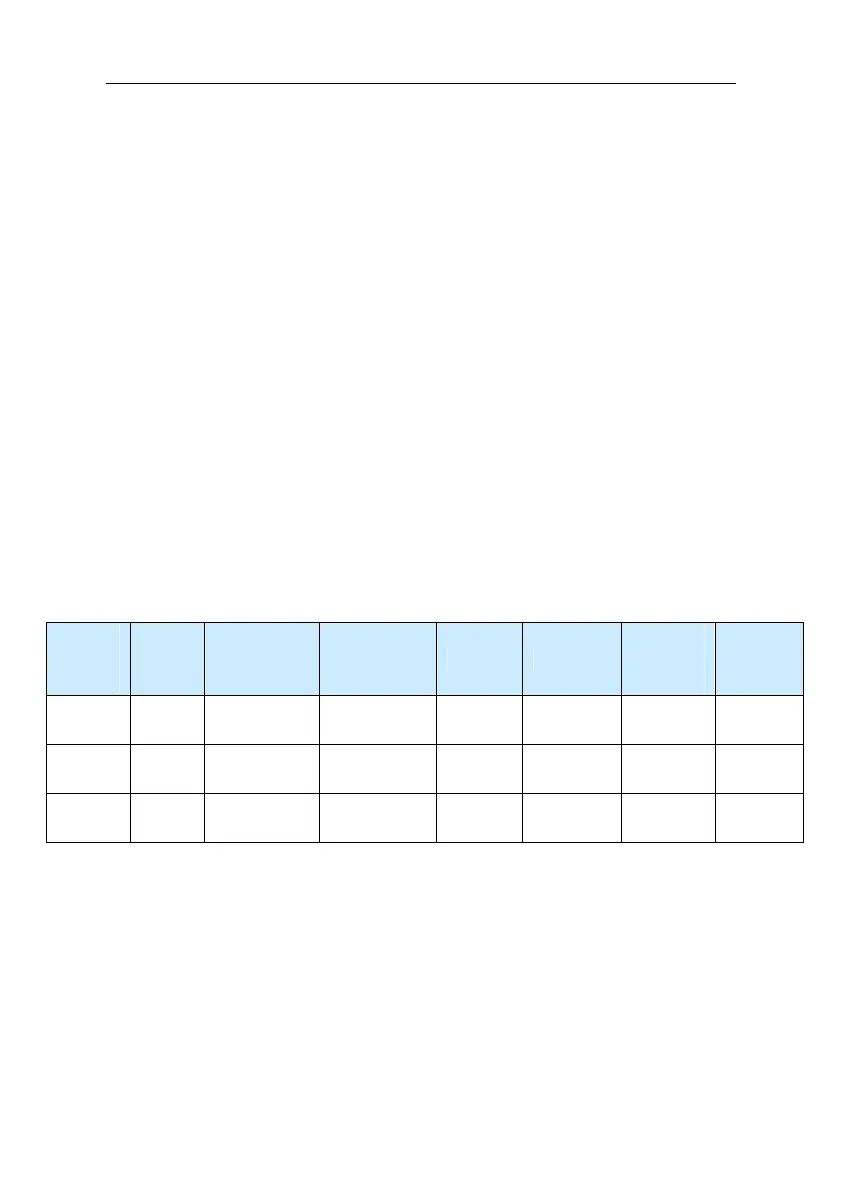

Table 7-3 Oil Pump Features Contrast

Oil

pump

type

Price

Volumetric

efficiency

Fluctuation

(stability)

Noise Reliability

Pressure

(single

stage)

Rotation

speed

Gear

pump

Low Low Medium Medium High Low Medium

Plunger

pump

Middle High High High Low Medium Low

Screw

pump

High Medium Low Low Medium High High

7.3.2 Servo Motor Prototyping

Rated rotation speed selection of servo motor

Characteristic curve of servo motor (permanent magnet synchronous servo

motor) shown in Figure 7-1.

Loading...

Loading...