Maintenance

Maintenance Schedules

84 9831/7750-1 84

Interval ( h) Calendar Equivalent

1000 Yearly

1500 Eighteen months

2000 Two years

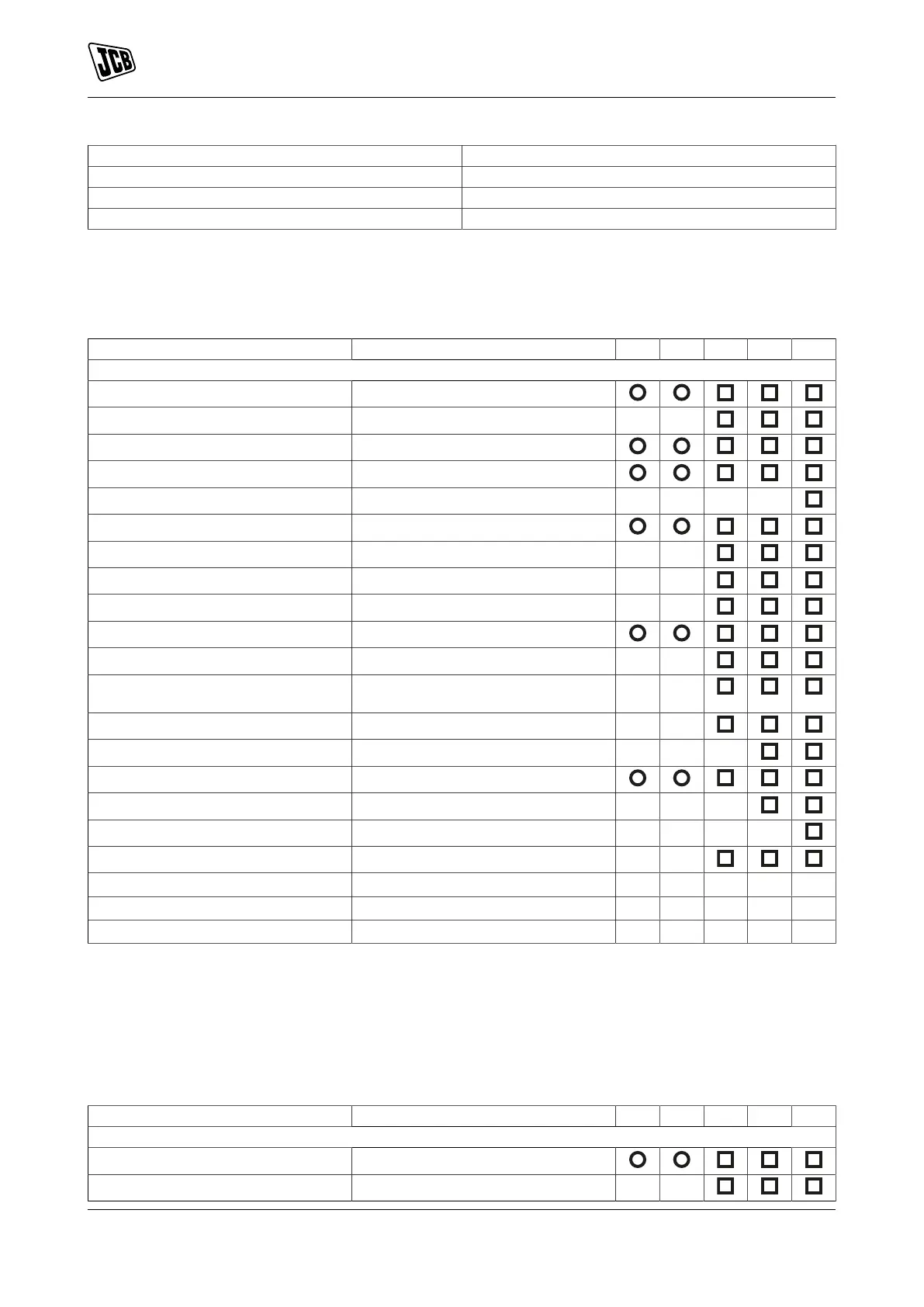

Pre-start Cold Checks, Service Points and Fluid Levels

Table 11.

Component Task 10 50 500 1,000 2,000

Engine

Oil Level Check

Oil and Filter

(1, 2, 3, 5)

Change

Coolant Quality/ level Check

Coolant or Oil Leaks Check

Coolant System

(6)

Drain and Fill

Water Separator Check for Contamination and Drain

Water Separator Element/ Fuel Filter Change

Fuel Filter (inline) Change

Fuel tank and filler Drain/Clean

All Hoses - Condition Check

Radiator

(4)

Clean

FEAD (Front End Accessory Drive)

belt

Check

Air Cleaner Outer Element

(4)

Change

Air Cleaner Inner Element Change

Air filter dust valve Check

Valve Clearances

(5)

Check and adjust

Oil Filler and Dipstick O-rings Change

FEAD belt Change

Injectors

(5)

Change

Injector(s) Leak-Off Rail

(5)

Change

High Pressure Fuel Lines

(5)

Change

(1) If operating under arduous conditions, do an engine oil flush (use the normal recommended engine oil)

every 250 h. Change the engine oil and filter every 250 h.

(2) The oil service interval will be affected if there is a high sulphur content in the fuel. Refer to Fuel System

(3) Engine oil and oil filter change at first 50 h then every 400 h thereafter.

(4) If operating in dusty adverse working environments, do these jobs more frequently.

(5) These jobs must be done by a qualified engineer.

(6) Change at first 4,000 h (4 years) then every 2,000 h thereafter.

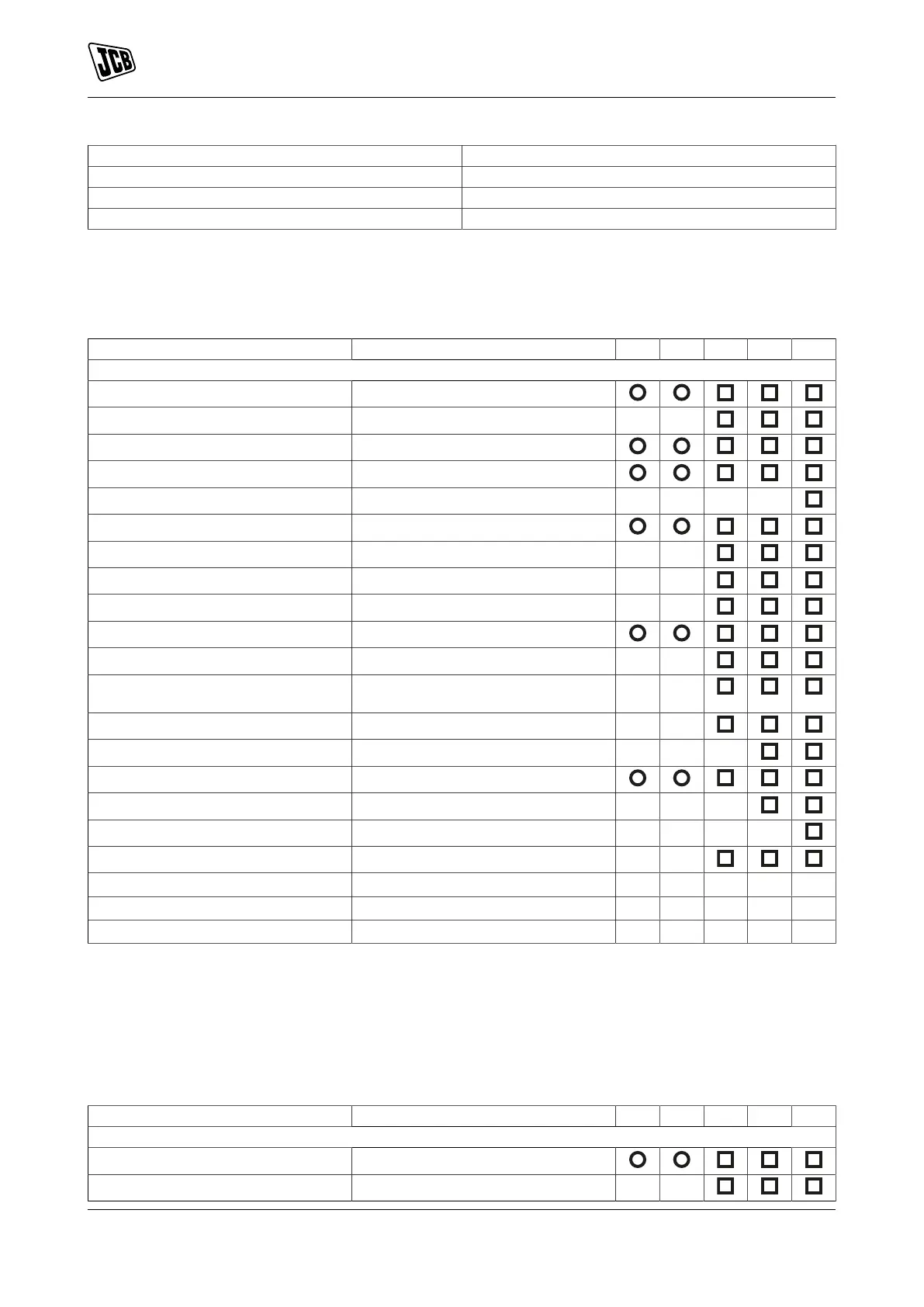

Table 12.

Component Task 10 50 500 1,000 2,000

Drum and Steering

Drum Scrapers Clean

Drum Rubber Buffers Check

Loading...

Loading...