Maintenance

Maintenance Schedules

85 9831/7750-1 85

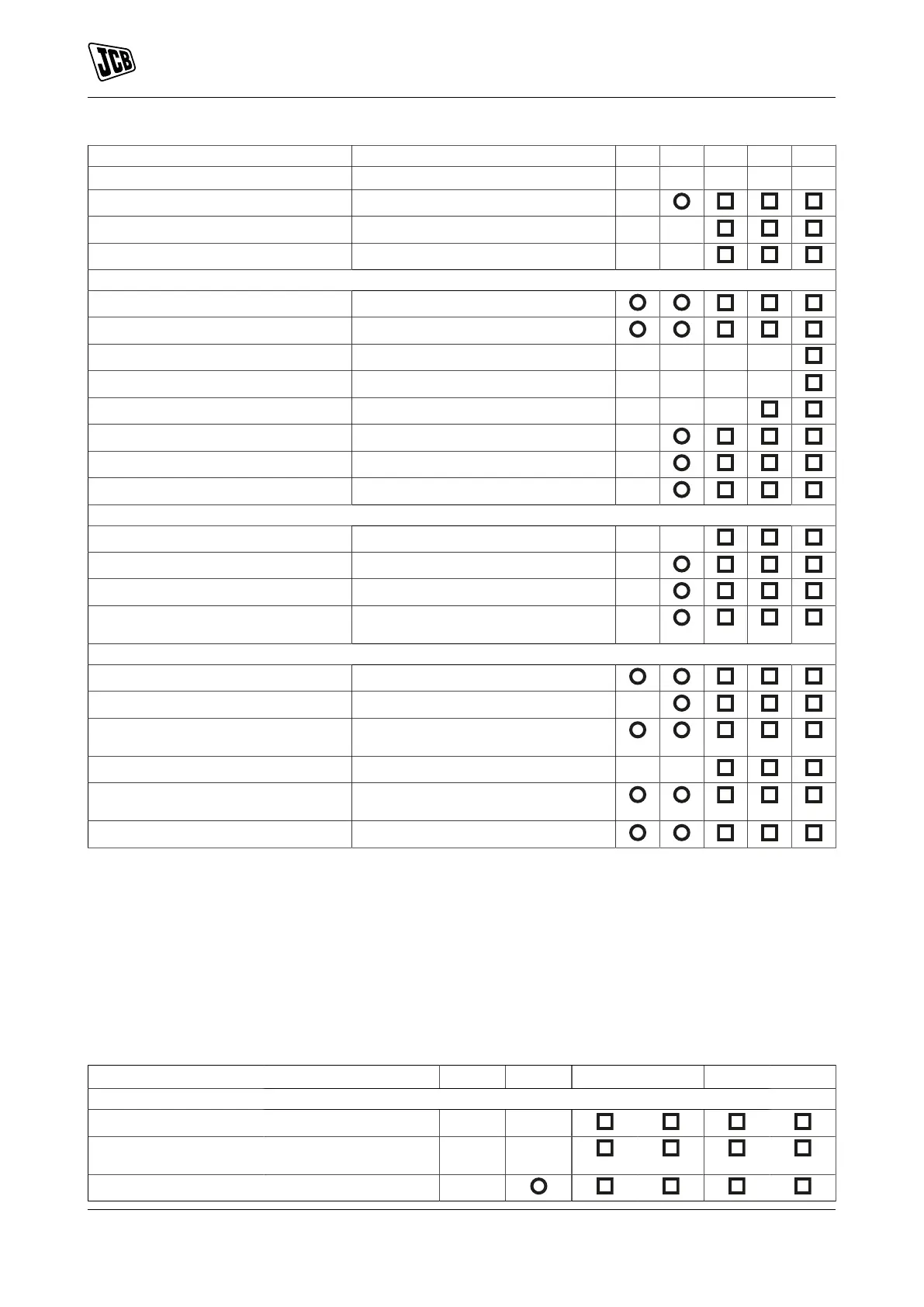

Component Task 10 50 500 1,000 2,000

Drum bearing

(3)

Lubricate

Drum Distance Spacers / Buffer

(1)

Check/ Change(if necessary)

Articulation Joint Check

Steering Cylinder Bolts Check

Hydraulics

Hydraulic System Check (Leaks)

Oil Check (Level)

Oil Replace

Oil Reservoir Clean

Oil Filter

(2)

Replace

Hoses - Damage or Leaks Check

Steering Rams - External Leaks Check

Rams - Chrome Condition Check

Electrics

Battery charge indicator Check

Wiring for Chafing/Routing Check (Condition)

Battery Mounting Check (Condition)

Battery Terminals for Condition and

Tightness

Check (Condition)

Bodywork and Cab

Safety Decals/Notes Check

Cab Isolation Mounts Check

ROPS (Roll-Over Protective Struc-

ture)

Check (Condition)

Condition of Paintwork Check

Seat Belt Condition and Security (If

fitted)

Check

Machine Generally Check for Damage and Clean

(1) Check the tightness of the bolts/screws every day for the first week (when machine is new), then thereafter

every 500 h.

(2) Change at recommended interval - or when the warning light is on.

(3) Drum bearing must be lubricated after 4,000 h of operation.

Functional Tests and Final Inspection

Start the engine to do these maintenance tasks. Engine can be started, if the drive lever is in park brake position.

It is not mandatory to occupy the operator seat before starting the engine.

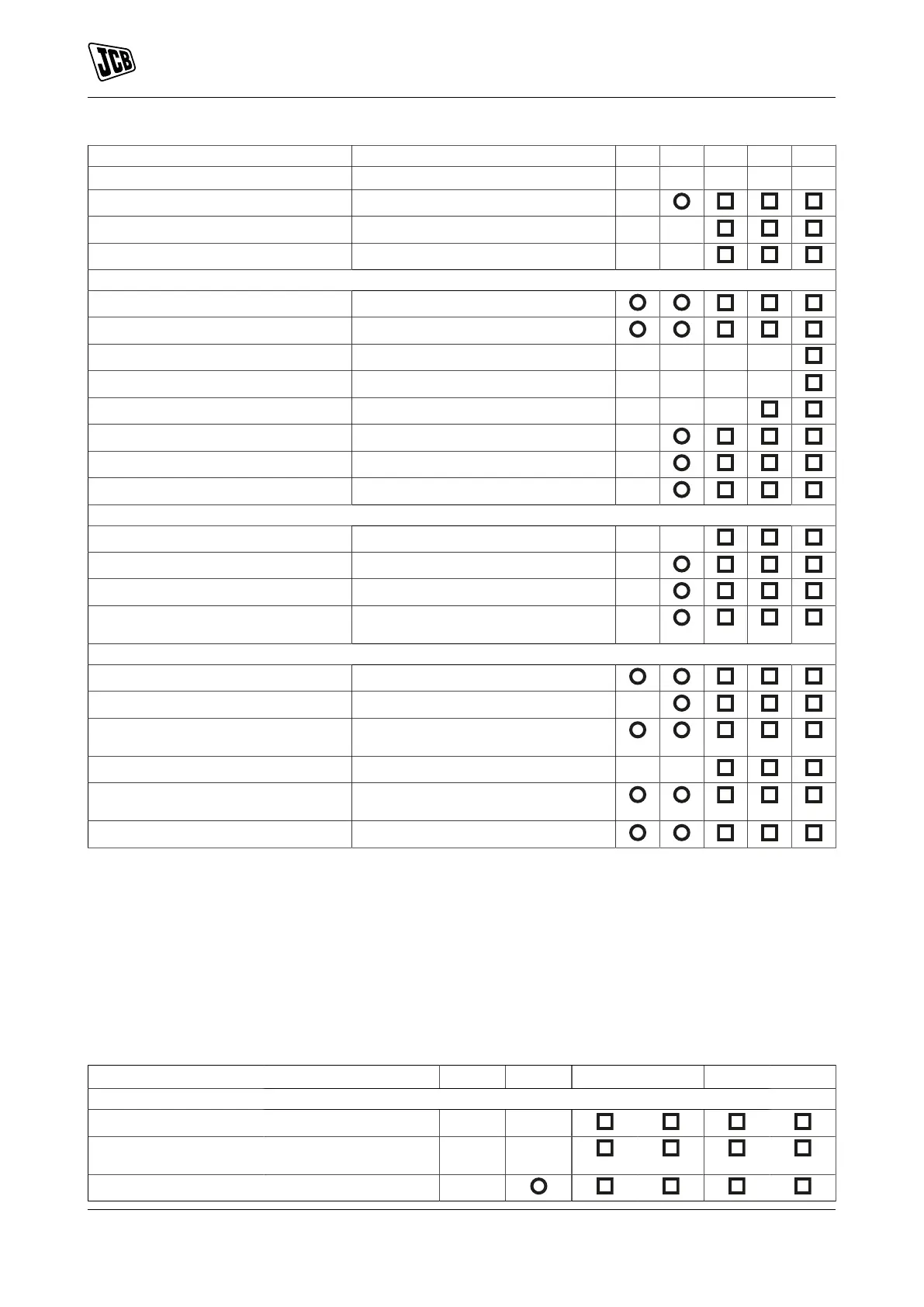

Table 13.

Item Operation 10 h 50 h

100 h

(1)

500 h 1,000 h 2,000 h

Engine

Idle Speed Check and Adjust

Maximum No load con-

dition.

Check

Exhaust smoke. Check

Loading...

Loading...