Maintenance

Fault-Finding

122 9831/0650-3 122

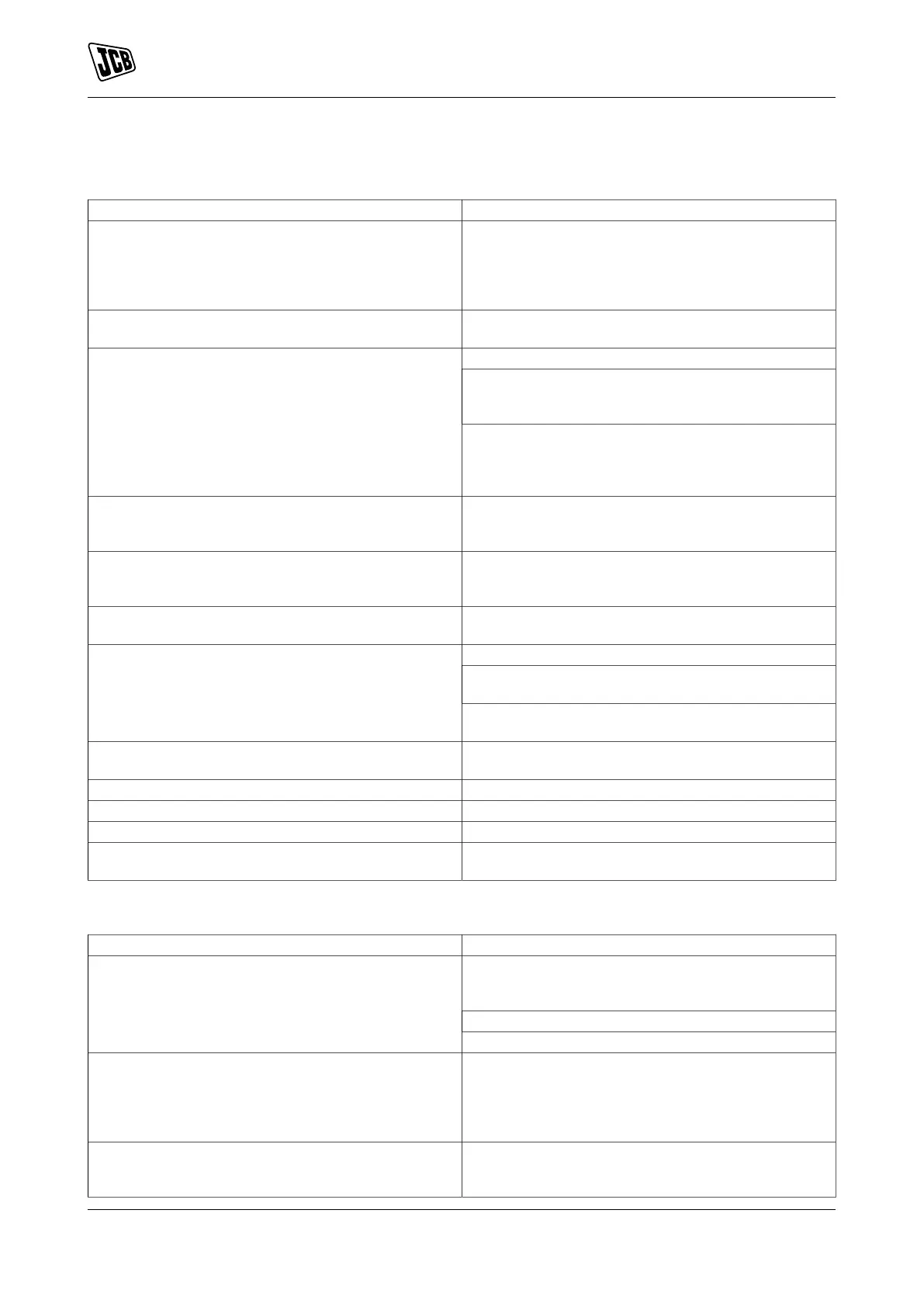

Table 27. Engine - Poor Running at Idle

Cause Remedy

Coolant temperature sensor fault Check the electrical connection at the coolant sen-

sor. Check the correct electrical wires for open or

short circuits. test the coolant sensor. If engine will

not reach operating temperature refer to the following

table. Refer to Table 45..

Engine mounts over-tightened, damaged or loose. Verify condition of mounts. Refer to the machine's

service manual for correct adjustment procedure.

Replace defective high pressure fuel lines.

WARNING: DO NOT repair defective fuel lines. If

there is a fuel leak remove and discard the neces-

sary components and install new ones.

Fuel injection lines leaking.

WARNING: Fine jets of fluid at high pressure can

penetrate the skin. Keep face and hands well clear of

pressurised fluid and wear protective glasses. If fluid

penetrates your skin, get medical help immediately.

Fuel is aerated. Check the low pressure fuel system for loose con-

nections and possible air ingress points. Rectify and

bleed the fuel system.

Fuel lift pump not operating correctly (fuel supply in-

adequate).

Check that the lift pump operates and delivers fuel to

the fuel injection pump. Check the correct electrical

wires for open or short circuits.

Fuel filter(s) blocked, fuel supply restricted. Check/replace the fuel filter(s). Check fuel lines for

restriction.

Stop the engine.

Replace the fuel filters. Operate the engine with a

temporary supply of the correct grade of clean fuel.

Fuel is contaminated or incorrect grade diesel fuel

used.

WARNING: Dirty fuel will cause damage to the fuel

injection pump and injectors.

Inlet and exhaust valve clearances set incorrectly. Set the valve clearances to the recommended clear-

ances.

Engine compression low in one or more cylinders. Check the engine compression.

One or more fuel injector worn or malfunctioning. Check the electrical connections at the injectors.

Electrical sensor fault. Check the electrical connections at the sensors.

Worn or malfunctioning high pressure fuel pump. Do all the necessary fault finding checks before re-

moval of the high pressure fuel pump.

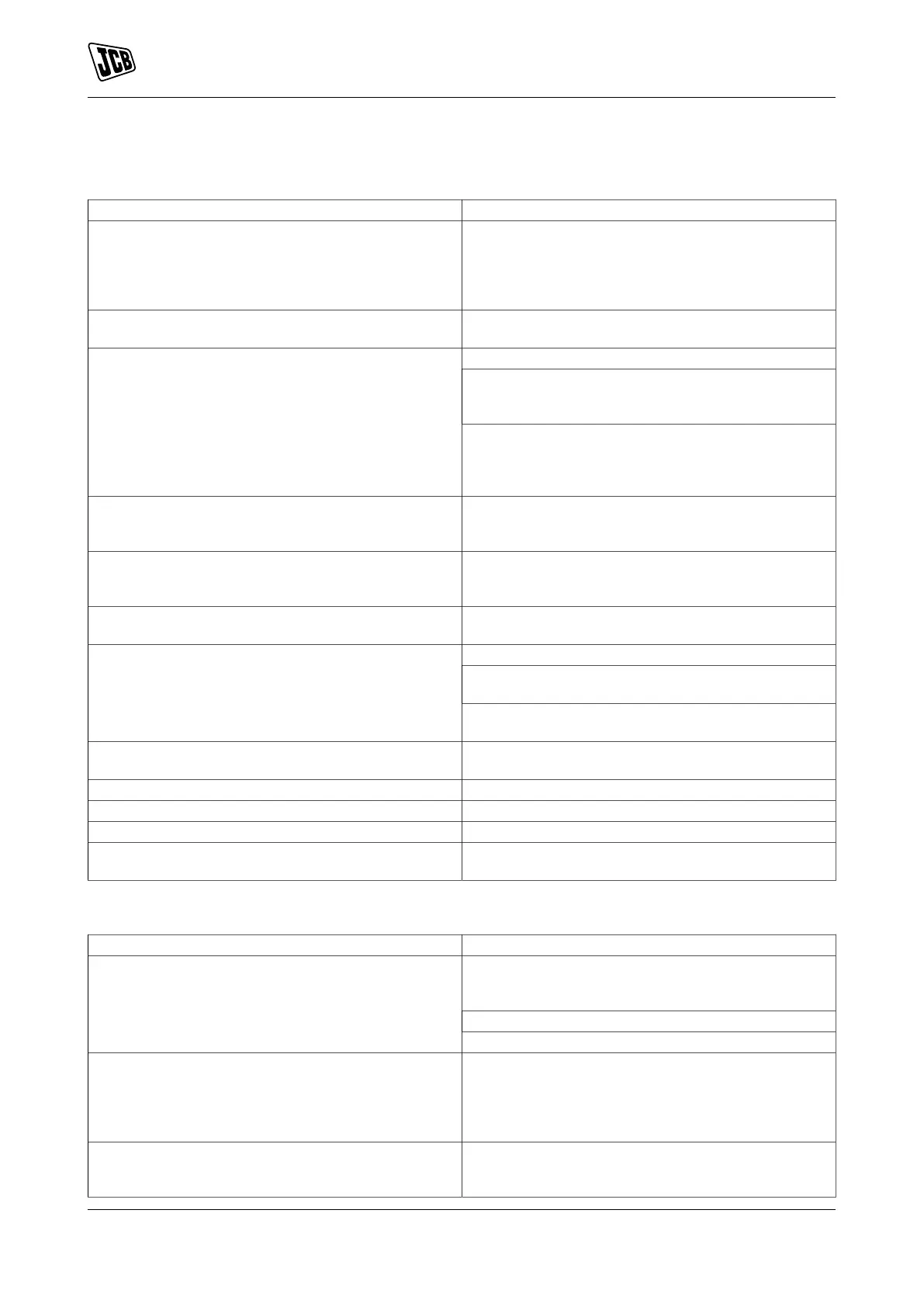

Table 28. Engine - Noise Excessive

Cause Remedy

Check the tensioner and inspect the drive belt for

loading. deterioration, Make sure water pump, ten-

sioner pulley, fan alternator turn freely.

Check for paint/oil or other material on pulleys.

Drive belt squeal, insufficient tension or abnormally

high loading.

Check the tension of accessory drive belts.

Coolant temperature sensor fault Check the electrical connection at the coolant sen-

sor. Check the correct electrical wires for open or

short circuits. test the coolant sensor. If engine will

not reach operating temperature refer to the following

table. Refer to Table 45..

Intake air or exhaust leaks. Table 13. Engine - Exhaust Smoke Excessive (Black

Smoke) and Table 14. Engine - Exhaust Smoke Ex-

cessive (White/Blue Smoke).

Loading...

Loading...