4 - 2

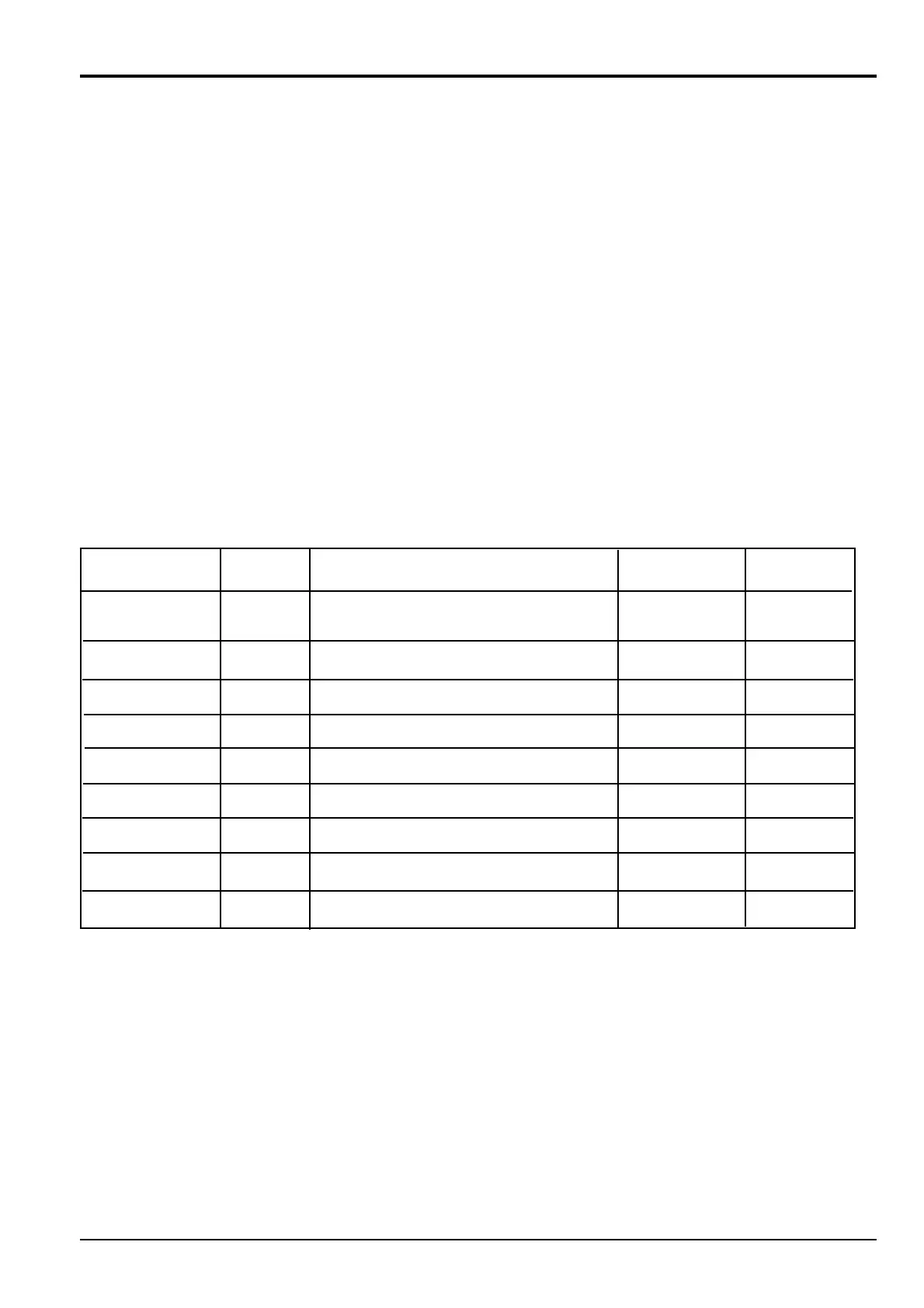

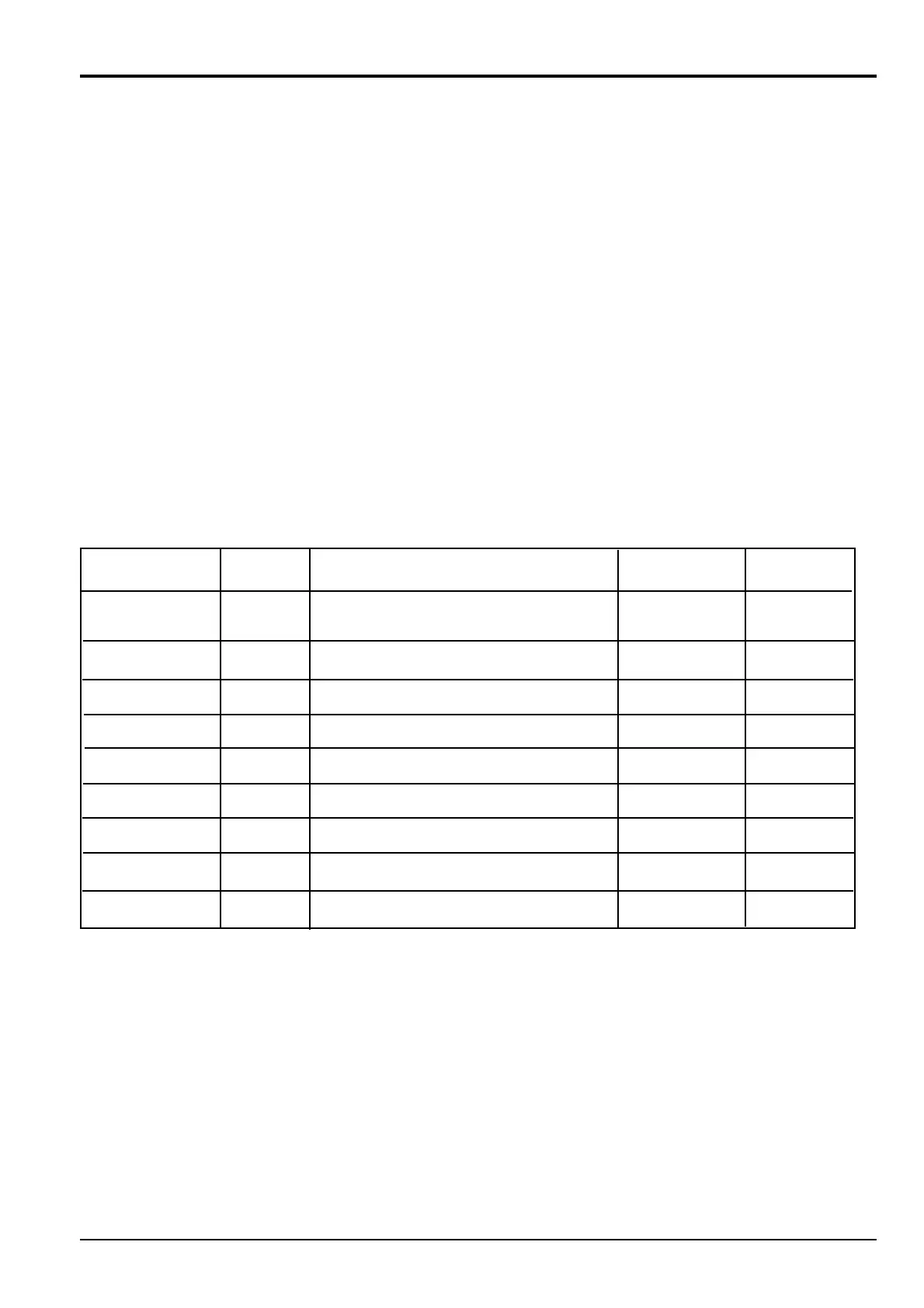

Pressure Measurement Measurement

Part Name bar (lb/in

2

) Method Port

Main Relief Standard: 314 - 320 bar (4554 - 4641 lb/in

2

) Dipper Relief G1(G2)

Power Boost: 343 - 350 bar (4975 - 5076 lb/in

2

)

Boom Port Relief Raise 358 - 365 bar (5192 - 5294 lb/in

2

) Boom Up Relief G2

Lower 295 - 305 bar (4278 - 4423 lb/in

2

) Boom down Relief G2

Bucket Port Relief Open/Close 358 - 365 bar (5192 - 5294 lb/in

2

) Bucket Relief G2

Dipper Port Relief Out/In 358 - 365 bar (5192 - 5294 lb/in

2

) Dipper Relief G1

Swing Port Relief Left/Right 275 - 285 bar (3988 - 4133 lb/in

2

) Swing Relief G1

Pilot Relief 37 - 43 bar (536 - 624 lb/in

2

) Lever Neutral G3

Accumulator 15 ± 5 bar (217 ± 72.5 lb/in

2

)G3

Track Motor Relief 338 - 348 bar (4902 - 5047 lb/in

2

) G1(G2)

Section E Hydraulics

9803/6410

Section E

4 - 2

Issue 1

Pressure Testing

Pressure Testing - General

Confirmation of the oil Temperature

Confirm the oil temperature is between 45° - 55° C using the

self check function. If the temperature is low use the following

warm-up procedure.

Warming-up Procedure

1 Turn the Throttle Control to mid-range and make sure the

Work Mode Selection Switch is set to S.

2 Press the One Touch Idle Switch.

3 Run the engine until the Coolant Temperature gauge

reads within the normal (green) range.

4 Set the Servo Isolator Switch to ON to enable the

hydraulic servo controls to be operated.

5 Operate the bucket control slowly until it reaches one end

of its travel and leave it there for 30 seconds.

6 Operate the bucket control slowly to the other end of its

travel and leave it there for 30 seconds.

7 Repeat steps 5 and 6 for 10 minutes to warm up the

hydraulic circuit.

8 Now operate the excavating controls three to five times in

each direction to distribute warm hydraulic oil around the

system.

Loading...

Loading...