6 - 5

Removal and Replacement (cont’d)

Replacement (cont’d)

5 Apply grease through the check valve to adjust the

track tension (see Tracks and Running Gear,

Checking/Adjusting the Track Tension, Section 3).

Motor Bleeding

Bleeding must be done whenever a track motor is being

fitted.

Note: If a track gearbox assembly is being fitted to the

machine with the motor attached, bleed it as described in

step 1 of page 6 - 3.

When the motor is being fitted to a gearbox already fitted to

the machine, bleed the air from the motor by one of the

three methods detailed below.

Note: Method 1 will take considerable time as air in the

motor is very difficult to purge. Methods 2 or 3 may be

quicker.

Method 1

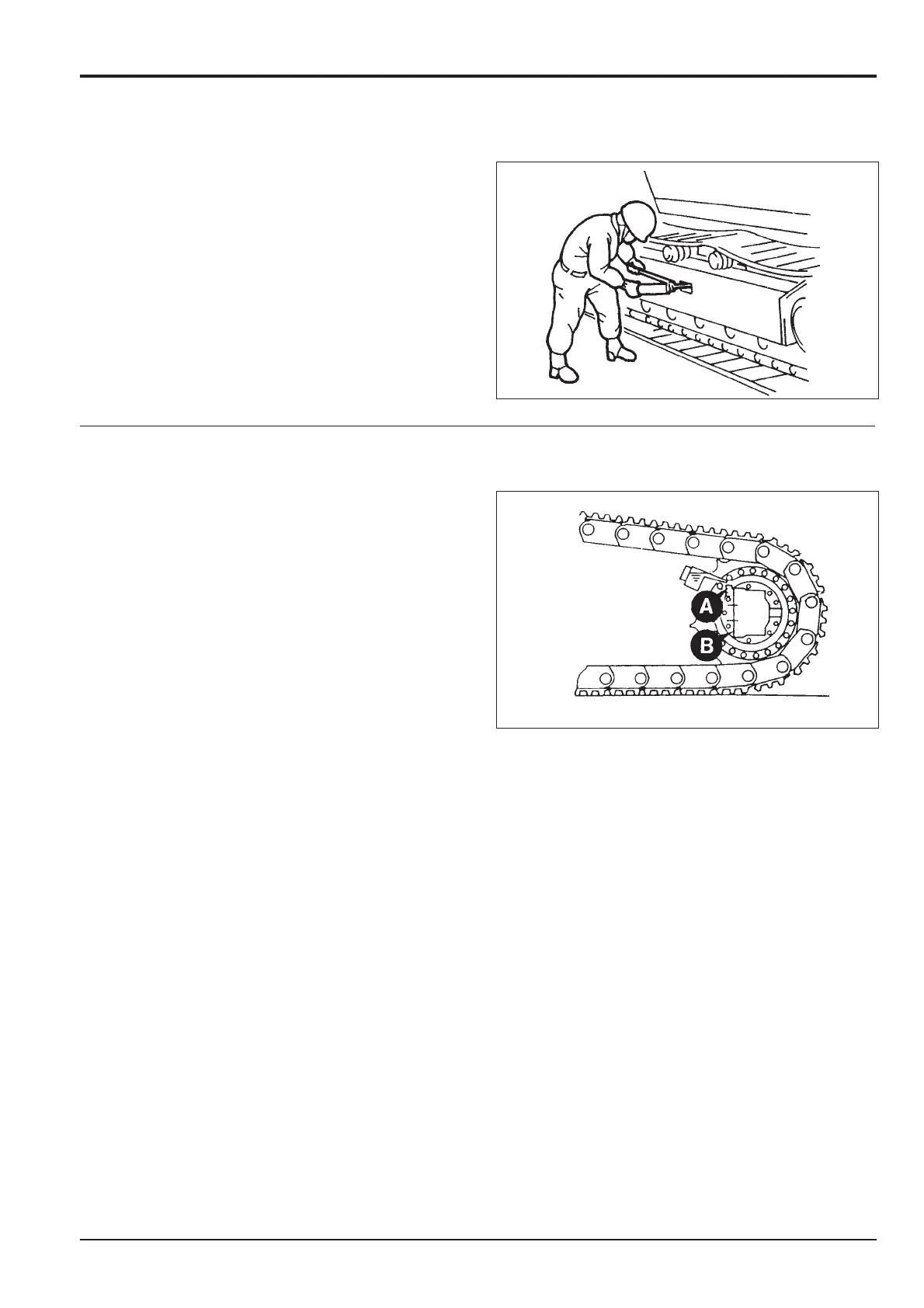

After fitting the motor but before connecting the pipework,

remove plug from upper drain port A but make sure that a

plug is fitted to lower drain port B.

Fill the motor with specified hydraulic oil through port A.

Connect the pipes.

Method 2

Fit the motor and connect all pipes except the two drains.

Remove plug from port A. Make sure that a steel plug is

fitted to bottom drain port B.

Run the engine and operate the track control lever slightly,

without allowing the sprocket to rotate. If necessary, prevent

the sprocket from turning by means of a steel bar or tube

jammed in the track. Return the lever to neutral when air-

free oil flows from port A. Connect the drain pipes.

Method 3

Fit the motor and connect all pipes. Prevent the sprocket

from turning by means of a steel bar or tube jammed in the

track. Run the engine and fully select the track control lever

for about 1 minute. This will fill the motor case with oil.

Section F Transmission

9803/6410

Section F

6 - 5

Issue 1

Traction Motor/Reduction Gear

Loading...

Loading...