5 - 6

Changing the Return Filter Element

1 Prepare the Machine

Position the machine on level ground. Stop the engine.

Remove the starter Key.

2 Locate the Return filter. See Components Location

Diagram at the end of this section.

3 Release Tank Pressure.

See Releasing Tank Pressure.

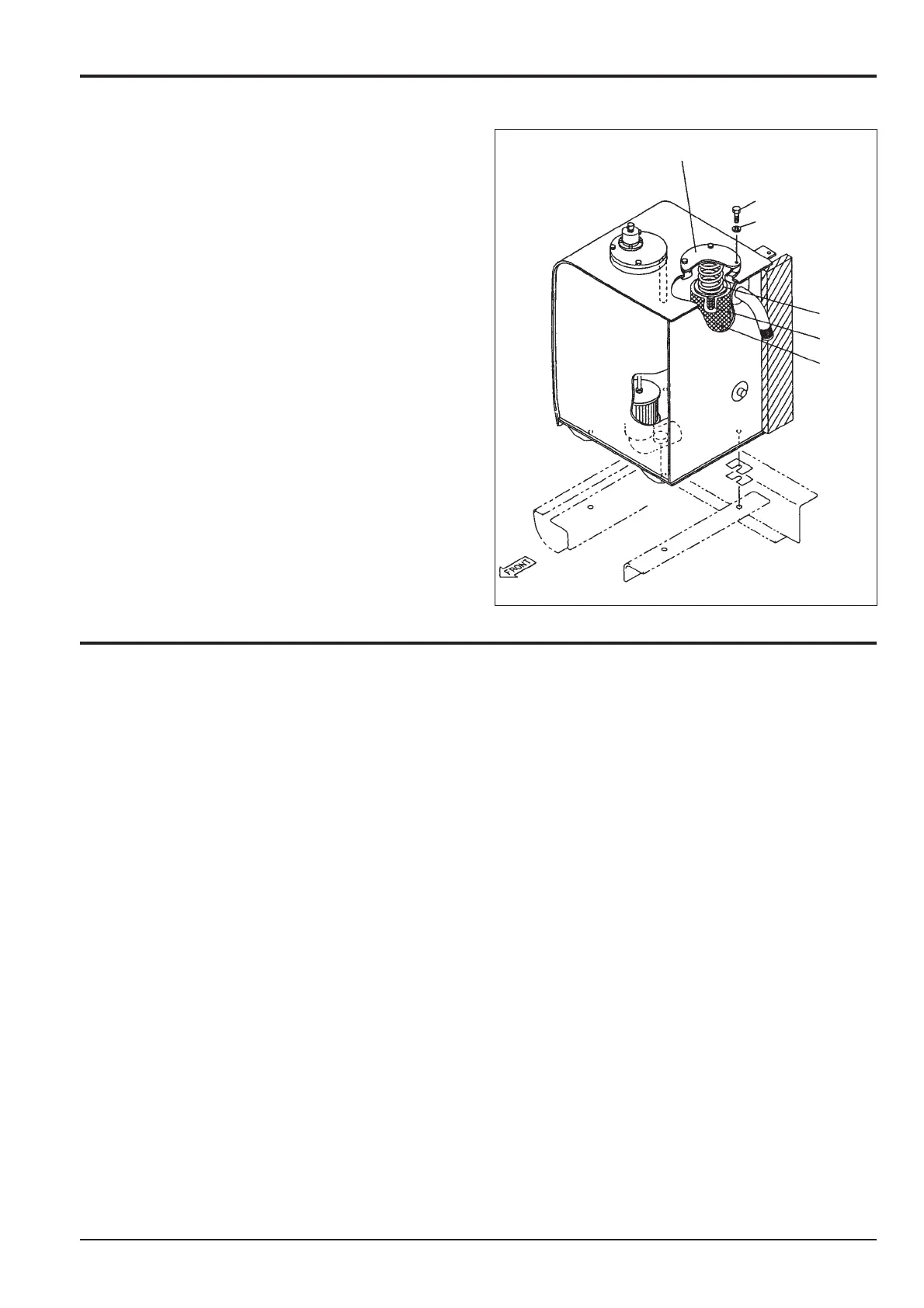

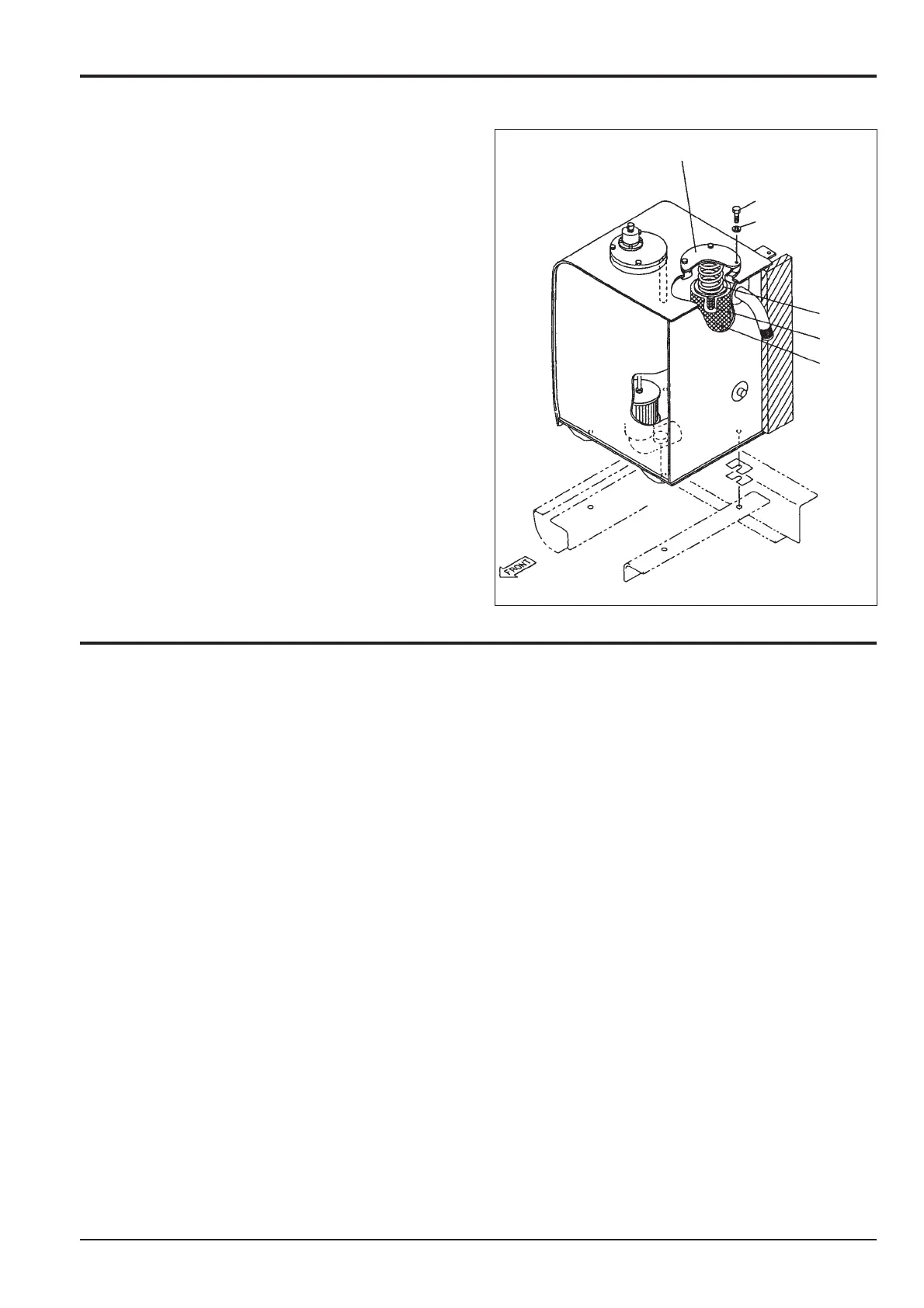

4 Removing the Element

a Remove the retaining bolts A and washers B and

take off the cover plate C complete with its 'O'-ring

seal.

b Remove the spring D, bypass valve E and element

F.

5 Fit a New Element

Re-assemble in reverse order, using a new filter element

F and replace the 'O'-ring with a new one if the one

removed is worn or damaged.

6 Seal the system

Refit the cover plate C and secure with bolts A and

washers B.

Flushing Filters

A slave hydraulic flushing element can now be obtained for

the machine. It is a mandatory requirement that the hydraulic

system is flushed when:

1 The hydraulic system has become contaminated with

debris.

2 Major hydraulic components such as pumps, valve

blocks, ram, tanks, motors etc. are changed.

3 An oil sample report indicates that the system needs to

be cleaned.

The slave filter should be fitted in place of the main return

filter during flushing only.

1 Vent hydraulic tank pressure (see Releasing Tank

Pressure) and then remove tank cover C, main

hydraulic filter F, relief valve E and spring D.

2 Fit flushing filter element, relief valve G and spring D.

3 Refit tank cover C, ensuring that the ‘O’ ring is

positioned correctly.

4 Start up machine and test for leaks.

5 Run the machine as described below:

The filter should be left in the machine for a minimum of

4 hours, during which time all hydraulic services must

be operated a minimum of 20 times to ensure complete

system cleanliness.

6 After the required flushing time has elapsed, stop the

engine and vent hydraulic pressure (see Releasing

Tank Pressure).

7 Remove flushing filter element and save in a clean

condition until step 10 is completed.

8 Fit new main hydraulic filter and refit tank cover.

9 Take oil sample and send for analysis.

10 If analysis shows that the oil is out of specification the

flushing procedure should be repeated until analysis

confirms that the oil is satisfactory.

Element Required

SSP0061 All JS Machines up to and including JS160.

Section 3 Routine Maintenance

9803/6410

Section 3

5 - 6

Issue 2*

Hydraulics (continued)

C

A

B

D

E

F

*

Loading...

Loading...