14 - 5

Dismantling

Refer to the illustrations on pages 14 - 1 to 14 - 3 and the

component list on page 14 - 4. In the following procedures,

the part numbers in bold type (e.g. 71) correspond with the

numbers on the illustrations.

Before attempting to dismantle the hydraulic pump, drain all

oil, blank all inlet and outlet ports and wash the outer

surfaces with a suitable solvent to remove all dirt and dust.

Dry using compressed air.

Make different alignment marks across each sub-assembly

joint face as an aid to assembly.

The cylinder block assemblies, servo pump, relief valve and

proportional pressure reduction valve must be replaced as

complete assemblies.

The following procedures show a complete strip down, but,

unless absolutely necessary, avoid disturbing or dismantling

the control elements of the pump, i.e. those retained by

covers 30, 52 and 53 and by plugs 31 and 35. Any

interference with setting screws will affect pump output

control, necessitating precision re-setting on the bench.

The pump/regulator unit contains two pressure pumps, P1

and P2. Take care not to get the parts from one mixed in

with parts from the other.

During dismantling, record the number and dimensions of

shims. Take care to reassemble in the same manner.

Section E Hydraulics

9803/6410

Section E

14 - 5

Issue 1

Hydraulic Pump/Regulator

Note: Protect the clamping faces when supporting the pump

housing in the vice.

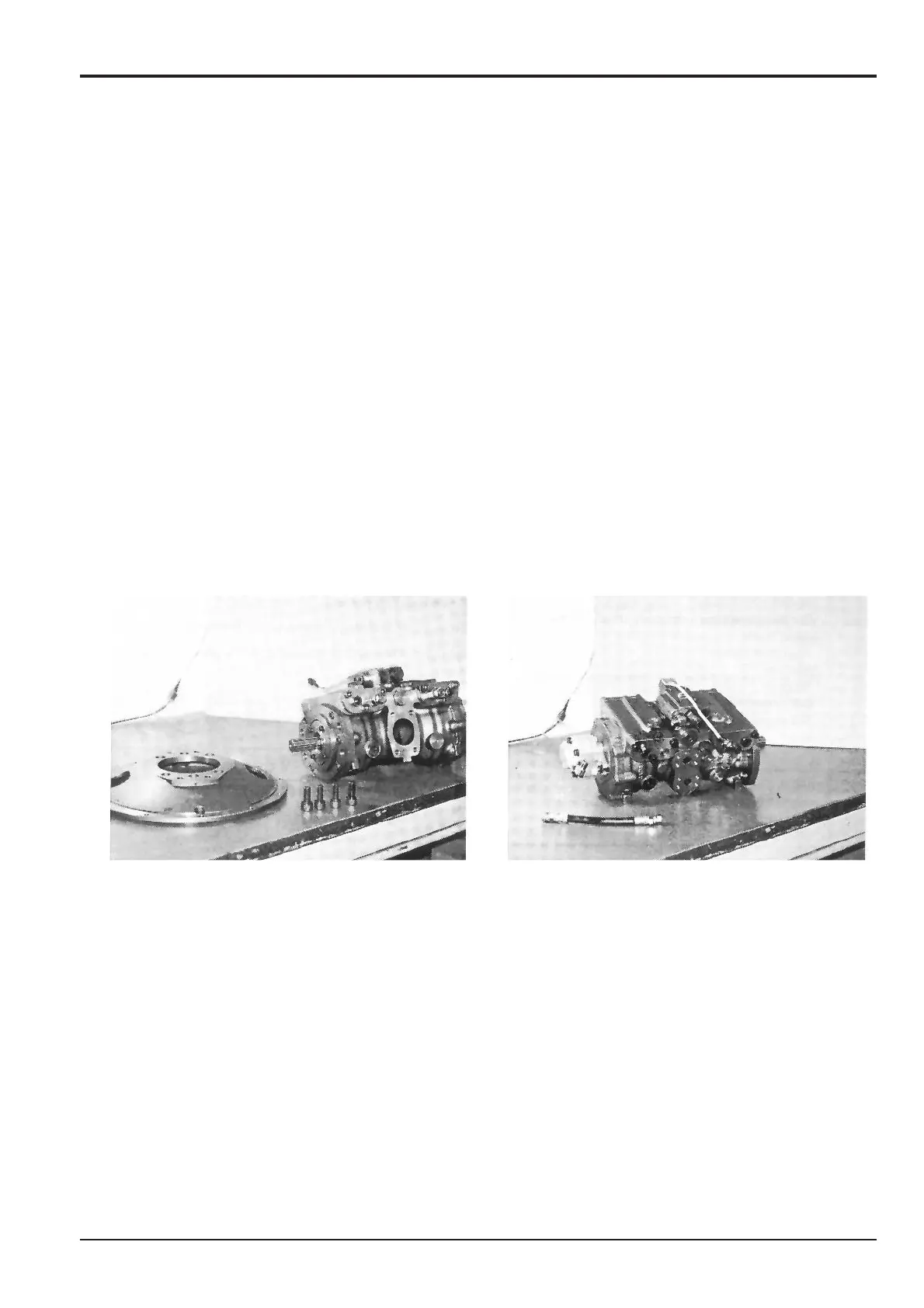

1 Support pump housing 1 in a vice, clamped across the

inlet and outlet port flanges. Unscrew the four socket

head bolts 71 and remove mounting flange 61.

2 Remove hose 59.

Loading...

Loading...