II.

MEASURES

TO

ELIMINATE

STITCHING

FAILURES

This chapter

covers

stitching

failures

and their corrective

measures,

e.g.thread

escape,

thread

breakage,

stitch-skipping,

needle breakage, thread trimmer failure and related problems.

(1) Thread escape

Phenomenon The machine fails to form the first, secondor third stitches and the thread slipsout of the

needle eye.

Possiblecauses ^The first stitch was skipped.

•The

thread left in the needle eye before starting was too short.

•The

thread take-up spring was

not

properly adjusted.

•The

bobbin

thread

was

too

short.

Corrective

measures

1) To preventthe first stitch from

being

skipped

A. Check

the

relative position

of

the

shuttle

to

the

needle.

Readjust it,

if

necessary.

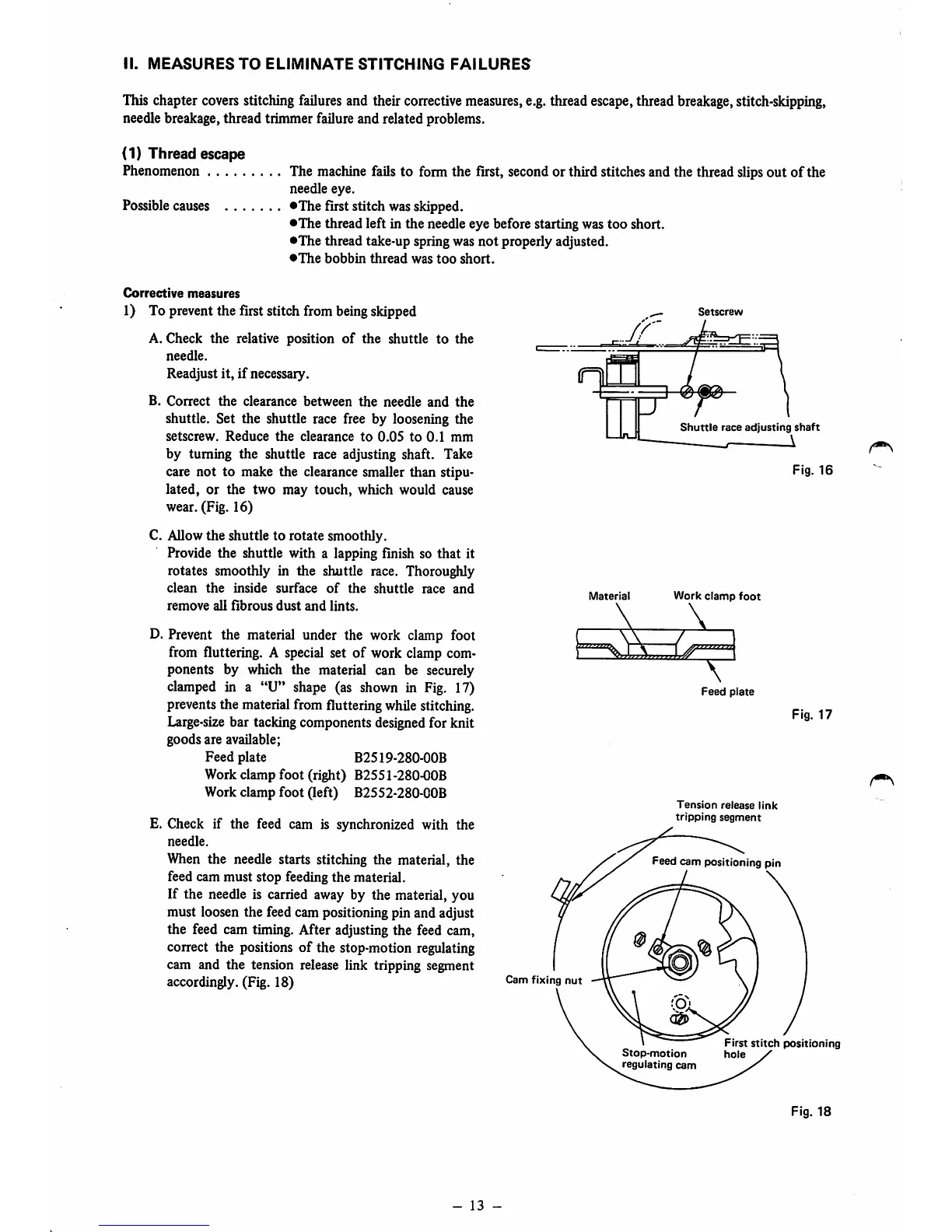

B.

Correct

the

clearance

between

the

needle

and

the

shuttle. Set the shuttle race free by loosening the

setscrew.

Reduce

the

clearance

to

0.05

to

0.1

mm

by tuming the shuttle race adjusting shaft. Take

care not to make the clearance smaller than stipu

lated,

or

the

two may touch, which would cause

wear. (Fig. 16)

C. Allow the shuttle to rotate smoothly.

Provide the shuttle with a lapping finish so

that

it

rotates smoothly in the shuttle race. Thoroughly

clean

the

inside

surface

of

the

shuttle

race

and

remove

all

fibrous

dust

and

lints.

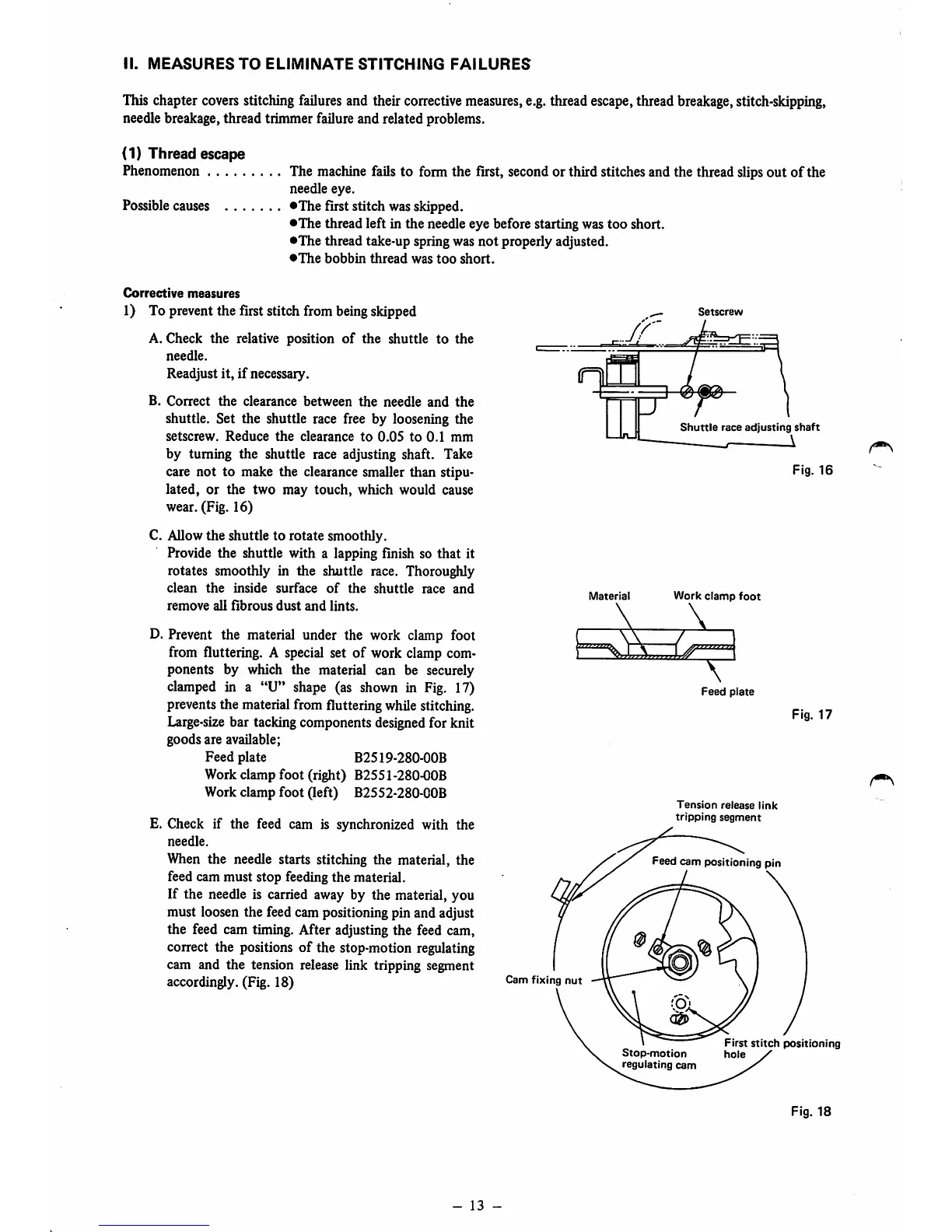

D. Prevent the material under the work clamp foot

from fluttering. A special set

of

work clamp com

ponents by which the material can be securely

clamped

in a "U" shape (as shown in Fig. 17)

preventsthe material from fluttering whilestitching.

Large-size bar tacking components designed for knit

goods are available;

Feed

plate B2519-280-00B

Work clamp foot (right) B2551-280-00B

Workclamp foot (left) B2552-280-00B

E. Check if the feed cam is synchronized with the

needle.

When the needle starts stitching the material, the

feed cam must stop feeding the material.

If the needle is carried away by the material, you

must loosen the feed cam positioningpin and adjust

the feed cam timing. After adjusting the feed cam,

correct the positions of the stop-motion regulating

cam and the tension release link tripping segment

accordingly. (Fig. 18)

-

13

Cam

fixing

nut

Setscrew

Shuttle

race

adjusting

shaft

1

Fig.

16

Material

Work

clamp

foot

Feed

plate

Tension

release

link

tripping

segment

Feed cam positioning pin

at>

Fig. 17

Stop-motion

regulating

cam

First

stitch

positioning

hole

Fig. 18

Loading...

Loading...