(5) Precautions when sewing synthetic materials

When

synthetic or blend materials are sewnwith synthetic threads,

special

attention shouldbe paidto the

follow

ing

points;

1) Protection of the thread against overheating

If the thread or the material is melted by a

needle

heated by the frictional heat produced

between

the

needle

and the material, take the following preventive measures;

A.

Replace

the motor

pulley

with either

B7101-280-00C

(50 Hz) or

B7102-280-00C

(60 Hz)

designed

for

synthetic material applications at a sewingspeed

of

1,700 s.p.m.

B.

Use

the

silicon

oil

lubricator.

C. Usea needle for synthetic materials.

D. Use a

finer

needle

to

reduce

friction.

2) Thread becomes fluffy

If the thread

becomes

fluffywhenstitching,

move

the

frame

thread

guide

(A)to the left and

increase

the stroke

of

the thread take-up lever.

3) Starting stitches are loose.

If loose stitches are formed at the start of

sewing,

adjust the timing of the cloth feed. Follow the method of

stardard adjustment mentioned in I-(l) and adjust the feed cam so that the cloth feed action is completed when

the pointed end of the needle is still in position within the specified adjusting

range

and closer to 10 mm

(25/64").

4) The blades

of

the shuttle driver are scratched.

Synthetic threads tend to scratch the thread path surface whenit is

released.

Remove

suchscratches by buffing

the

surfaces.

5) Smoothness

of

the thread paths

All the thread paths on the following components must be smooth enough to allow the thread to pass without

friciton;

Shuttle

driver

B1813-980-000

Shuttle

B1818-280-000

Shuttle

race spring B1815-980-000

Needle plate needle hole guide B2426-280-000

Needle

bar

thread

guide B1405-280-000

(Note) Without exception, use a DP x 5 needle. Do not use LQ x 5 which has been used with the conventional

LK-232 model, because this needle may scratch the periphery

of

the needle hole in the needle plate,

which may cause thread breakage.

(6)

Loose

stitching

(1) Firm stitching is not formed.

1) Adjustment

of

the feed timing

To obtain tight stitches, adjust the feed cam according to the instructions given in I-(l) so that the cloth feed

actioniscompleted by the timethe pointedend of the

needle

comes

downto near 7 mm (9/32") in height.

2) Adjustment

of

tension controller No. 2 and the thread take-up spring

Increase the tensions

of

both

components.

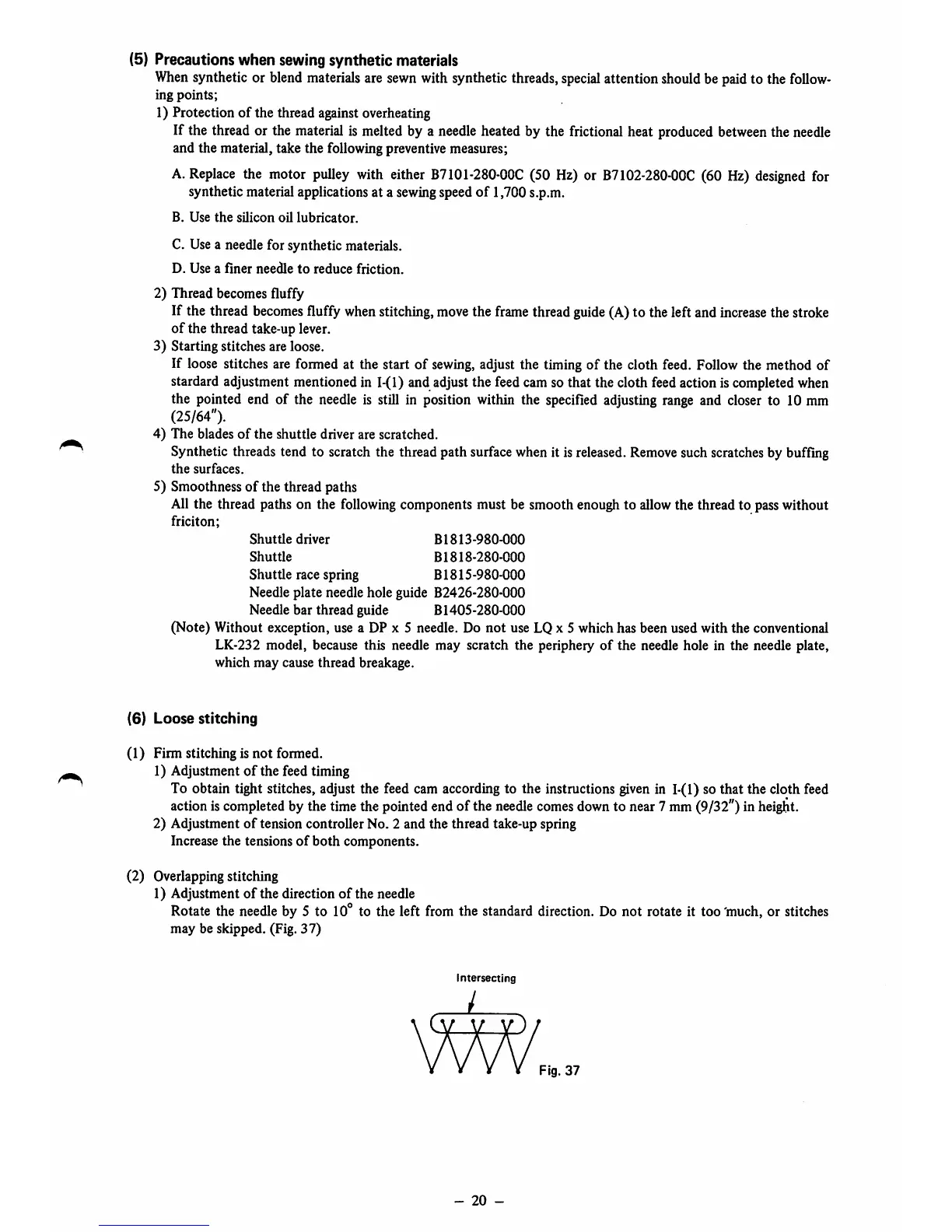

(2) Overlappingstitching

1) Adjustment

of

the direction

of

the needle

Rotate

the

needle

by 5 to

10**

to the left

from

the

standard

direction.

Do not rotate it too'much, or

stitches

may be skipped. (Fig.

37)

Intersecting

Fig.

37

-

20

-

Loading...

Loading...