III.

THINGS

TO

BE

NOTED

WHEN

DISASSEMBLING

AND

ASSEMBLING

THE

MACHINE

(1)

How

to

remove

the

shuttle

driver

shaft

When removing the shaft do not pull

out

the pin from the drive gear attached to the shuttle driver shaft under any

circumstances, or

the

needle bearings

under

the

rear sleeve will break.

To

remove

the

shuttle

driver

shaft,

loosen

the

setscrews

of

the

shuttle

driver

and

the

thrust

washer

and

screw

of

the

oscillating rock shaft located under the bed, and the shaft can be pulled out from the rear

of

the machine.

(2)

How

to

remove

the

main

shaft

1) Take

out

the needle.

2) Remove the stop-motion lever.

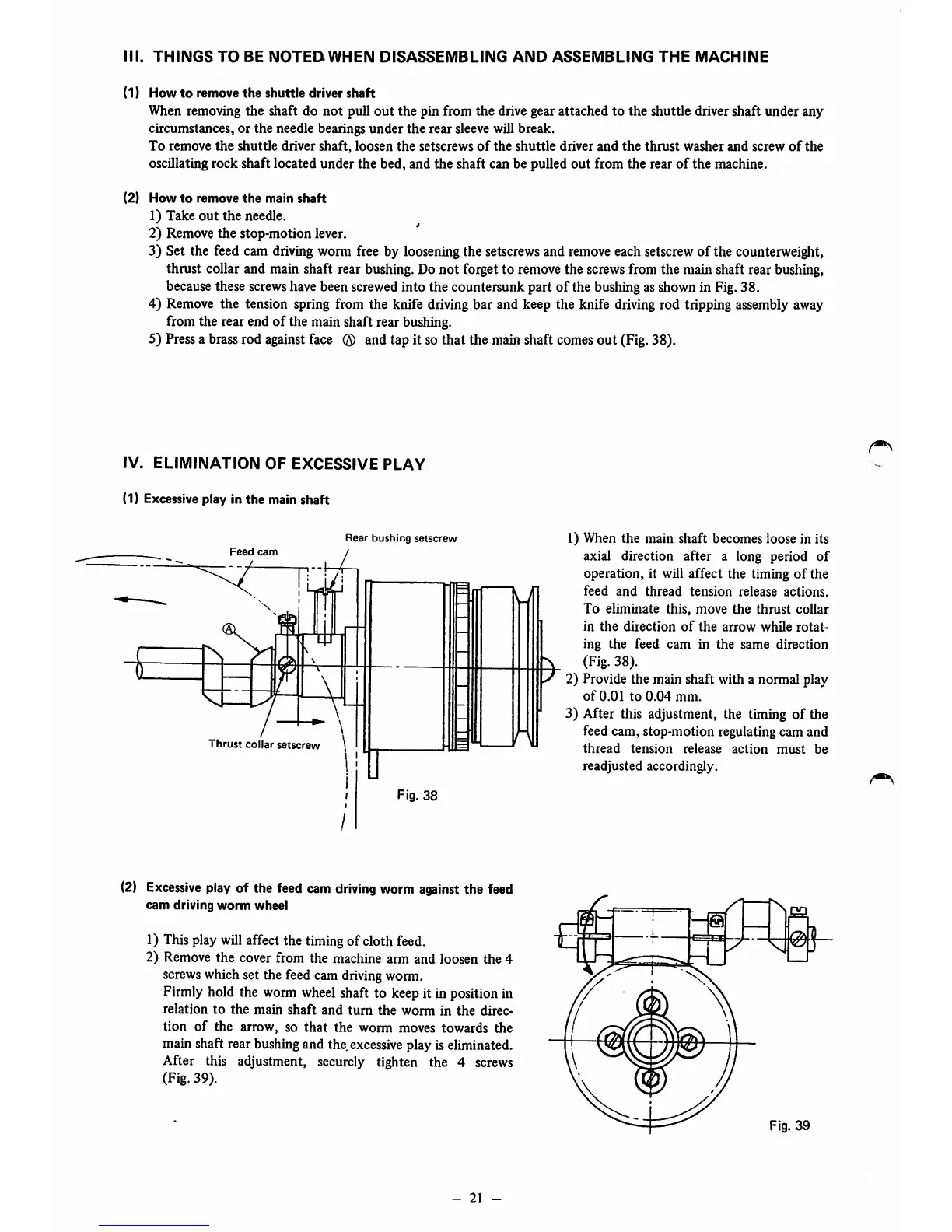

3) Set the feed cam

driving

worm free by loosening the setscrews and

remove

eachsetscrew of the counterweight,

thrust collar and main shaft rear bushing. Do not forget to remove the screwsfrom the main shaft rear bushing,

because these screwshave been screwed into the countersunk part

of

the bushing as shown in Fig.38.

4) Remove the tension spring from the knife driving bar and keep the knife driving rod tripping assembly away

from the rear end

of

the main shaft rear bushing.

5) Pressa brassrod againstface ® and tap it so that the main shaft comesout (Fig. 38).

IV.

ELIMINATION

OF

EXCESSIVE

PLAY

(1) Excessive play In

the

main shaft

Rear

bushing

setscrew

Feed

cam

Thrust

collar

setscrew

\

Fig.

38

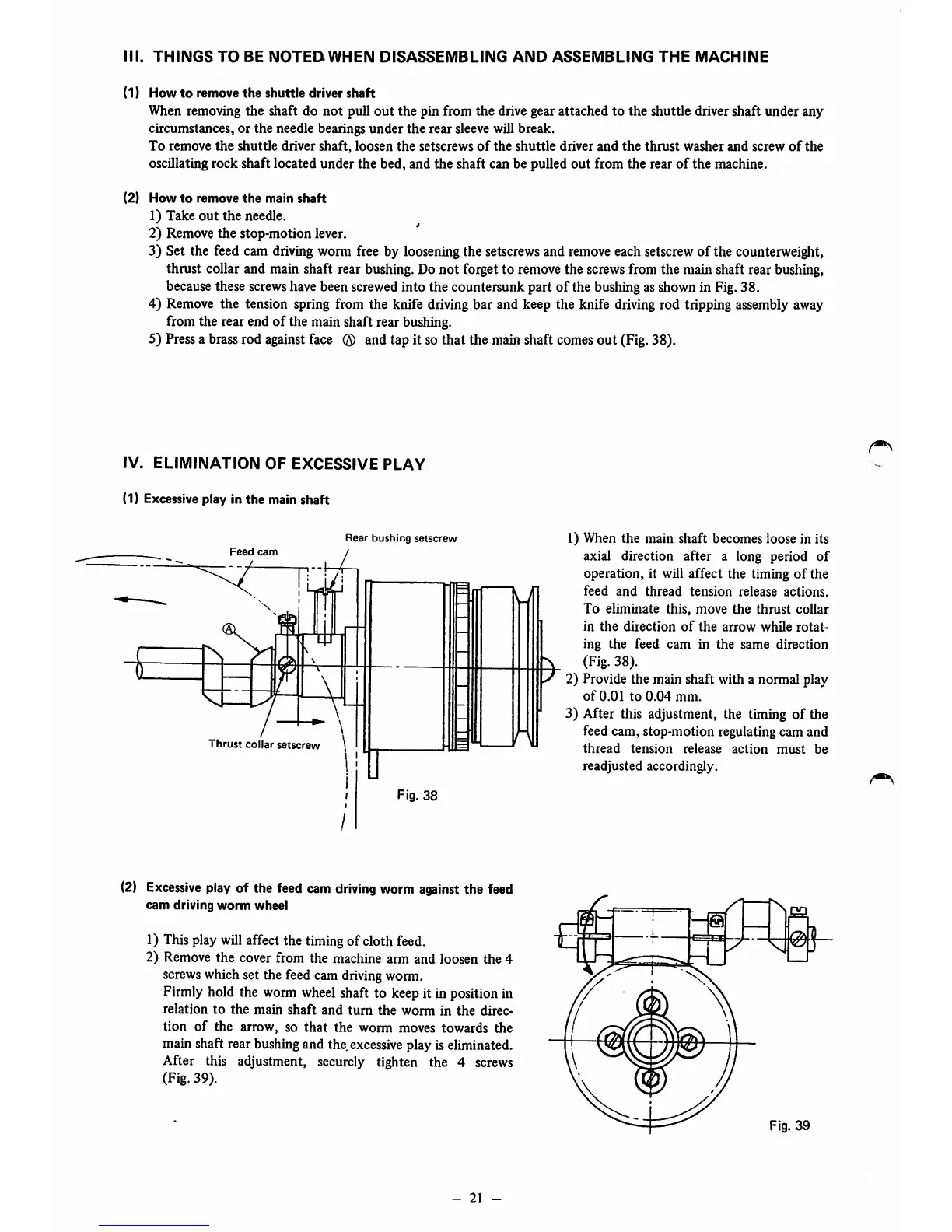

(2)

Excessive

play of the feed cam

driving

worm

against

the feed

cam

driving

worm

wheel

1) Thisplay willaffect the timingof cloth feed.

2) Remove

the

cover from the machine arm

and

loosen the 4

screwswhich set the feed cam drivingworm.

Firmly

hold the

worm

wheel

shaft to keepit in positionin

relation

to

the

main

shaft

and

turn

the

worm

in

the

direc

tion

of

the

arrow, so

that

the

worm moves towards

the

mainshaft rear bushingand the

excessive

play is eliminated.

After this adjustment, securely tighten the 4

screws

(Fig. 39).

-

21

-

1) When the main shaft becomes loose in its

axial direction after a long period

of

operation, it will affect the timing

of

the

feed

and

thread

tension

release

actions.

To

eliminate this,

move

the

thrust

collar

in

the

direction

of

the

arrow

while

rotat

ing the feed cam in the same direction

(Fig. 38).

2) Providethe main shaft with a normal play

of

0.01

to

0.04

mm.

3) After this adjustment, the timing of the

feed cam, stop-motion regulating cam and

thread

tension

release

action

must

be

readjusted accordingly.

Fig.

39

Loading...

Loading...