(2) Things to be checked after adjustment

1)

Turn

outer

sleeve

® 2

mm

(5/64")

in

the

reverse

direction

and

release

it.

The

outer

sleeve

shall

return

easily.

If there is any friction, clutch

spring

®

will

not

drive

the unit. If it

shakes

while

rotating,

sounds

will

be

produced

inthe

gears.

Correct

theend

face

of

thrust

collar

® or

replace

it

with

a

suitable

replacement

part;

B3016-980-00A

Thrust

collar for sleeve, 11.6

mm

thick

B3016-980-00B Thrust collar for sleeve, 11.75 mm thick

2) Tum

driving

pulley

® in the

direction

of the

arrow

untilthe shaftstopsand

check

that the top endof

reverse

rotation

preventing

latch ® is0.1 to 0.2 mmawayfromthe front

face

of the

pawl

of outer

sleeve

® .

If the clearance is greater than that, the latch willfail to

engage

with the pawland willidle and shakewhen the

motor is engaged. If the clearance is

too

small, clutch spring ® will not actuate the unit.

Replacethe clutch springwith a suitable one from amongthe 3 different types of

spring.

3)

When sounds are produced;

A.

If

the

gears make sounds;

a. Correct any

excessive

playin the axialdirection in the gears(largeand small).

b. Remove dust or foreign bodies from the gear teeth.

B. If a vibration noise is produced;

Check the clearance at the

reverse

rotation preventionlatch according to 2) of (2) Thingsto be checkedafter

adjustment.

4)

Other failures

The following failures may occasionally occur;

A. The shaft

of

the gear (large) on the mating surface with the clutch spring has worn out.

If its

diameter

becomes

19.2mm(3/4") or

less,

renew

the gear

assembly.

B. The clutch spring is defective.

If the inner

diameter

of the

clutch

spring

has

become

18.9mm(3/4")or

more,

or if the

spring

is

deformed,

renew

it.

(3)

Adjustment

of

the

thread

trimmer

components

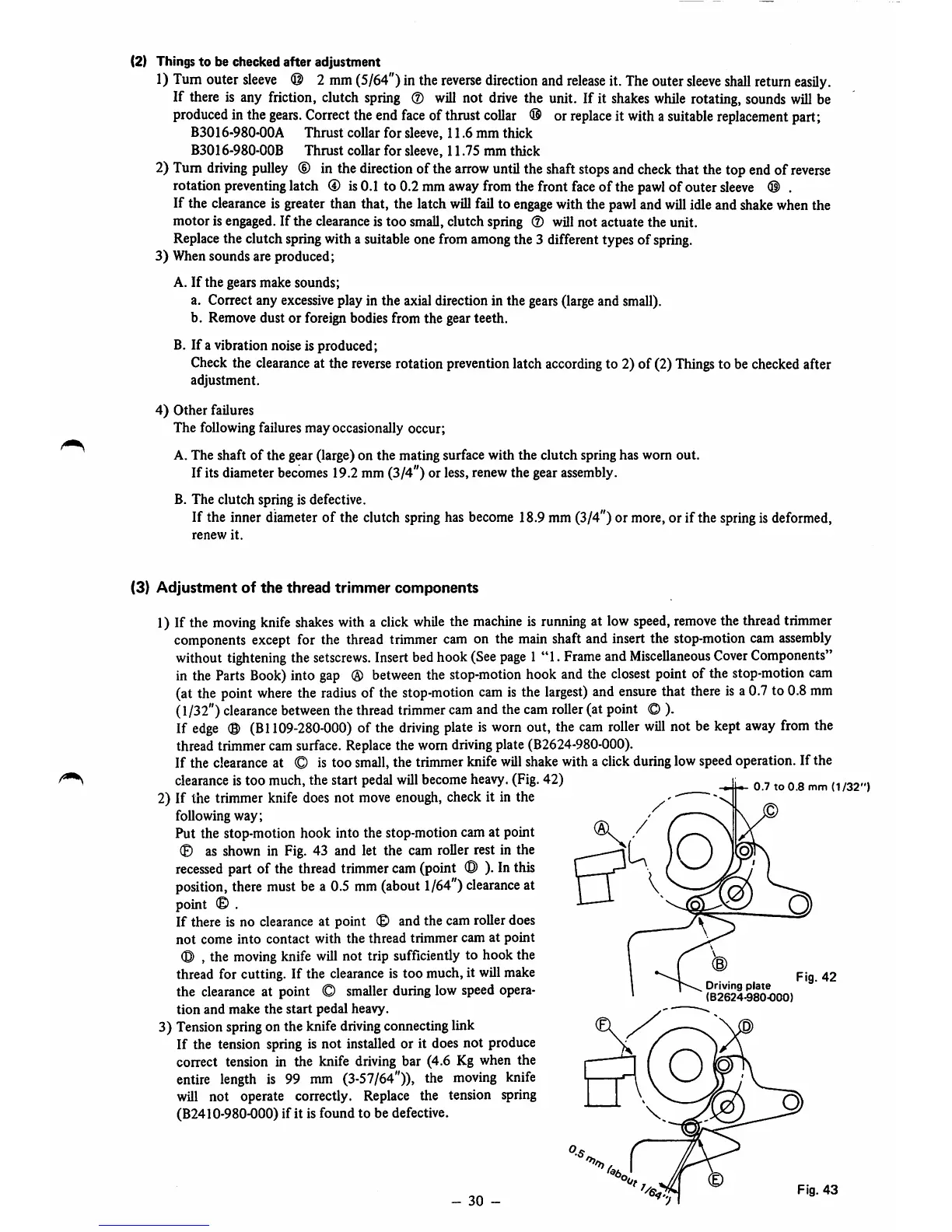

1) If the

moving

knife

shakes

with a click

while

the

machine

is

running

at low

speed,

remove

the thread trimmer

components

except

for the

thread

trimmer

cam

on the

main

shaft and insert the

stop-motion

cam

assembly

without

tightening

the

setscrews.

Insert

bed

hook

(See

page

1"1.

Frame

and

Miscellaneous

Cover

Components"

in the Parts

Book)

into gap ®

between

the stop-motion hook and the

closest

point of the stop-motion cam

(at the point

where

the

radius

of the

stop-motion

cam

is the

largest)

and

ensure

that

there

isa0.7 to 0.8

mm

(1/32")

clearance

between

the thread

trimmer

camand the cam

roller

(at point © ).

If

edge

©

(B1109-280-000)

of the

driving

plate

is

worn

out, the

cam

roller

will

not be

kept

away

from

the

thread trimmer cam surface.

Replace

the worn driving plate (B2624-980-000).

If the clearance at © is too small,the trimmer knife willshake with a click during low speed operation. If the

clearanceis too much, the start pedal will become heavy.(Fig. 42)

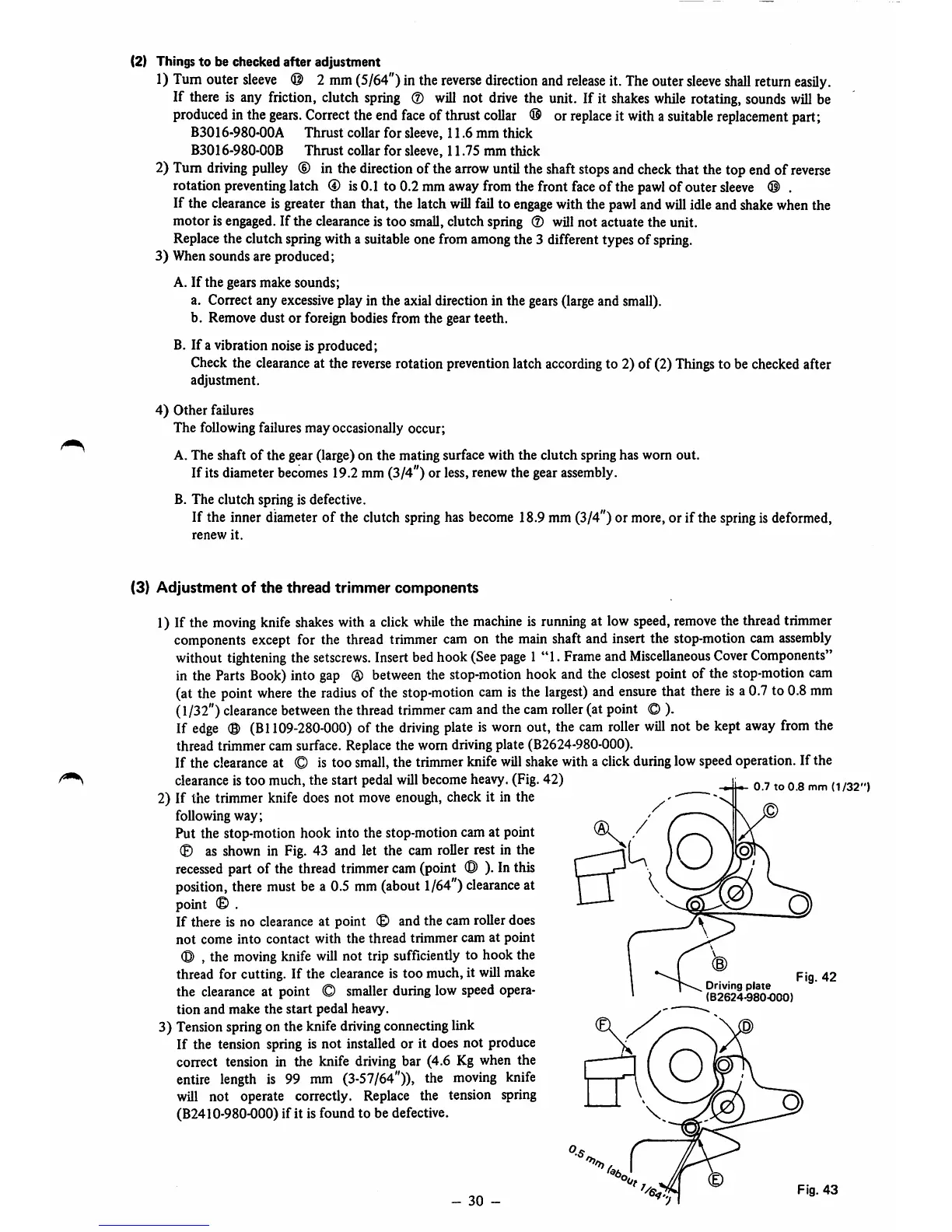

2) If the trimmer knife does not

move

enough, check it in the

following

way;

Put the stop-motion hook into the stop-motion cam at point

© as shown in Fig. 43 and let the cam roller rest in the

recessed

part of the

thread

trimmer

cam

(point ® ). In

this

position,

there

must

be a

0.5

mm

(about

1/64")

clearance

at

point © .

If there is no clearance at point © and the cam roller does

not

come

into

contact

with

the

thread

trimmer

cam

at

point

© , the

moving

knife will not trip sufficiently to hook the

thread for cutting. If the clearance is too much, it will make

the clearance at point © smallerduring low speed opera

tion

and

make the

start

pedal heavy.

3)

Tension

spring

on the knife

driving

connecting link

If the tension spring is not installed or it does not produce

correct tension in the knife driving bar (4.6 Kg when the

entire

length

is 99

mm

(3-57/64")),

the

moving

knife

will not operate correctly. Replace the tension spring

(B2410-980-000) if it is found to be defective.

-

30

0.7

to

0.8

mm

(1/32")

O

Driving

plate

(B2624-g80-000)

Fig.

42

Fig.

43

Loading...

Loading...