(9)

Adjustment

of

the

bobbin

winder

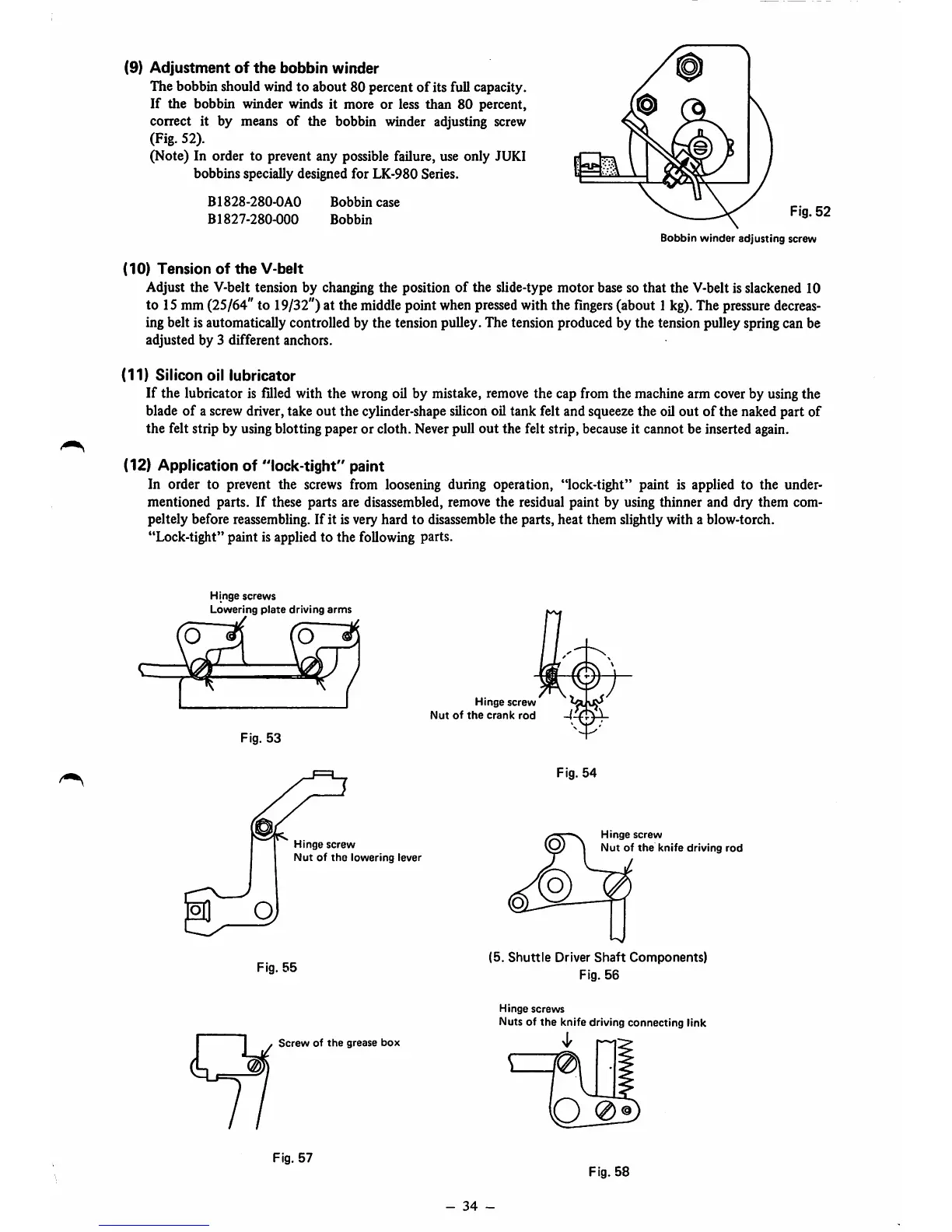

The bobbin should wind to about 80 percent

of

its full capacity.

If

the bobbin winder winds it more or less than 80 percent,

correct it by means

of

the bobbin winder adjusting screw

(Fig. 52).

(Note) In order to prevent any possible failure, use only JUKI

bobbins specially designed for LK-980 Series.

B1828-280-0A0

B1827-280-000

Bobbin

case

Bobbin

Fig.

52

Bobbin

winder

adjusting

screw

(10)

Tension

of

the

V-belt

Adjust the V-belt tension by changing the position

of

the slide-type motor base so

that

the V-belt is slackened 10

to 15mm

(25/64"

to 19/32") at the

middle

point

when

pressed

withthe

fingers

(about1

kg).

The

pressure

decreas

ing belt is automatically controlled by the tension pulley. The tension produced by the tension pulley spring can be

adjusted by 3 different anchors.

(11)

Silicon

oil

lubricator

If the lubricator is filled with the wrong oil by mistake, remove the cap from the machine arm cover by using the

blade

of

a screw driver, take out the cylinder-shape silicon oil tank felt and squeeze the oil out

of

the naked part of

the felt strip by using blotting paper or cloth. Neverpull out the felt strip, becauseit cannot be inserted again.

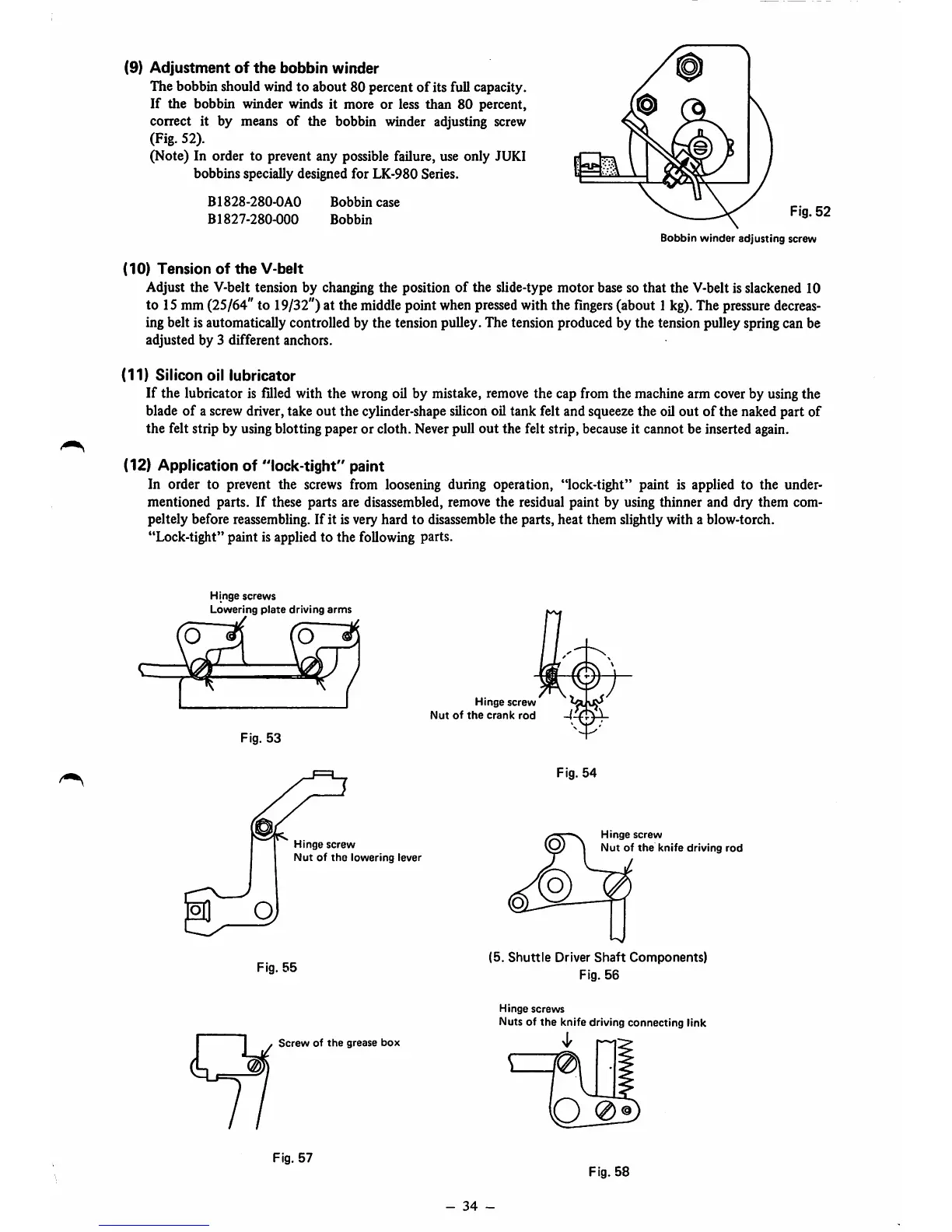

(12) Application of "lock-tight" paint

In order to prevent the screws from loosening during operation, "lock-tight" paint is applied to the under

mentioned parts. If these parts are disassembled, remove the residual paint by using thinner and dry them com-

peltely before reassembling. If it is very hard to disassemble the parts, heat them slightly with a blow-torch.

"Lock-tight" paint is applied to

the

following parts.

Hinge

screws

Lowering

plate

driving

arms

Fig.

53

Hinge

screw

Nut

of

the

lowering

lever

Fig.

55

Screw

of

the

grease

box

Fig.

57

Hinge

screw

Nut

of

the

crank

rod

Fig.

54

Hinge

screw

Nut

of

the

knife

driving

rod

(5.

Shuttle

Driver

Shaft

Components)

Fig.

56

Hinge

screws

Nuts of

the

knife driving

connecting

link

Fig.

58

-

34

-

Loading...

Loading...