(Note)

When

applying "Lock-tight" paint to the

above-mentioned parts, take care

not

to

contaminate neightboring parts

>vith

the

paint, or the contaminated parts may cause

malfunction.

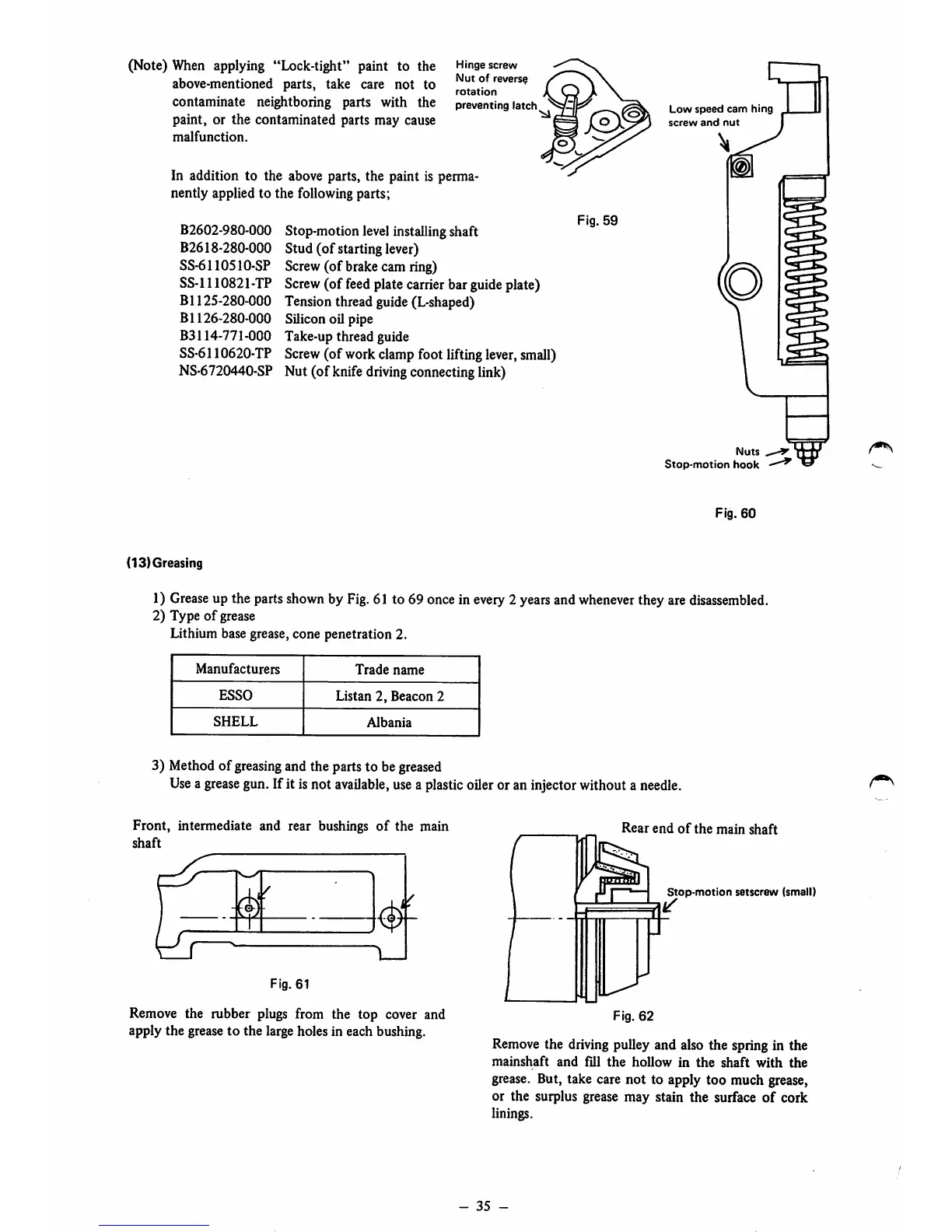

Hinge

screw

Nut

of

reverse

rotation

preventing

latch

In addition to the above parts, the paint is perma

nently applied to the following parts;

B2602-980-000 Stop-motion

level

installing shaft

B2618-280-000 Stud (ofstartinglever)

SS-6110510-SP Screw(ofbrake cam ring)

SS-1110821

-TP

Screw

(of

feed

plate carrier bar

guide

plate)

B1125-280-000 Tension thread guide(L-shaped)

B1126-280-000 Silicon oil pipe

B3114-771-000 Take-up thread guide

SS-6110620-TP

Screw

(of workclampfoot lifting

lever,

small)

NS-6720440-SP

Nut (of knife

driving

connecting link)

(13)Greasing

Fig.

59

Low

speed

cam

hing

screw

and

nut

Nuts

Stop-motion

hook

Fig.

60

1)

Grease

up the parts

shown

by

Fig.

61 to 69 oncein

every

2 yearsand

whenever

they are

disassembled.

2) Type

of

grease

Lithium base grease, cone penetration 2.

Manufacturers

Trade

name

ESSO

Listan 2,

Beacon

2

SHELL

Albania

3) Methodof

greasing

and the parts to be greased

Use

a

grease

gun. If it is not

available,

usea plastic oileror an injector without a

needle.

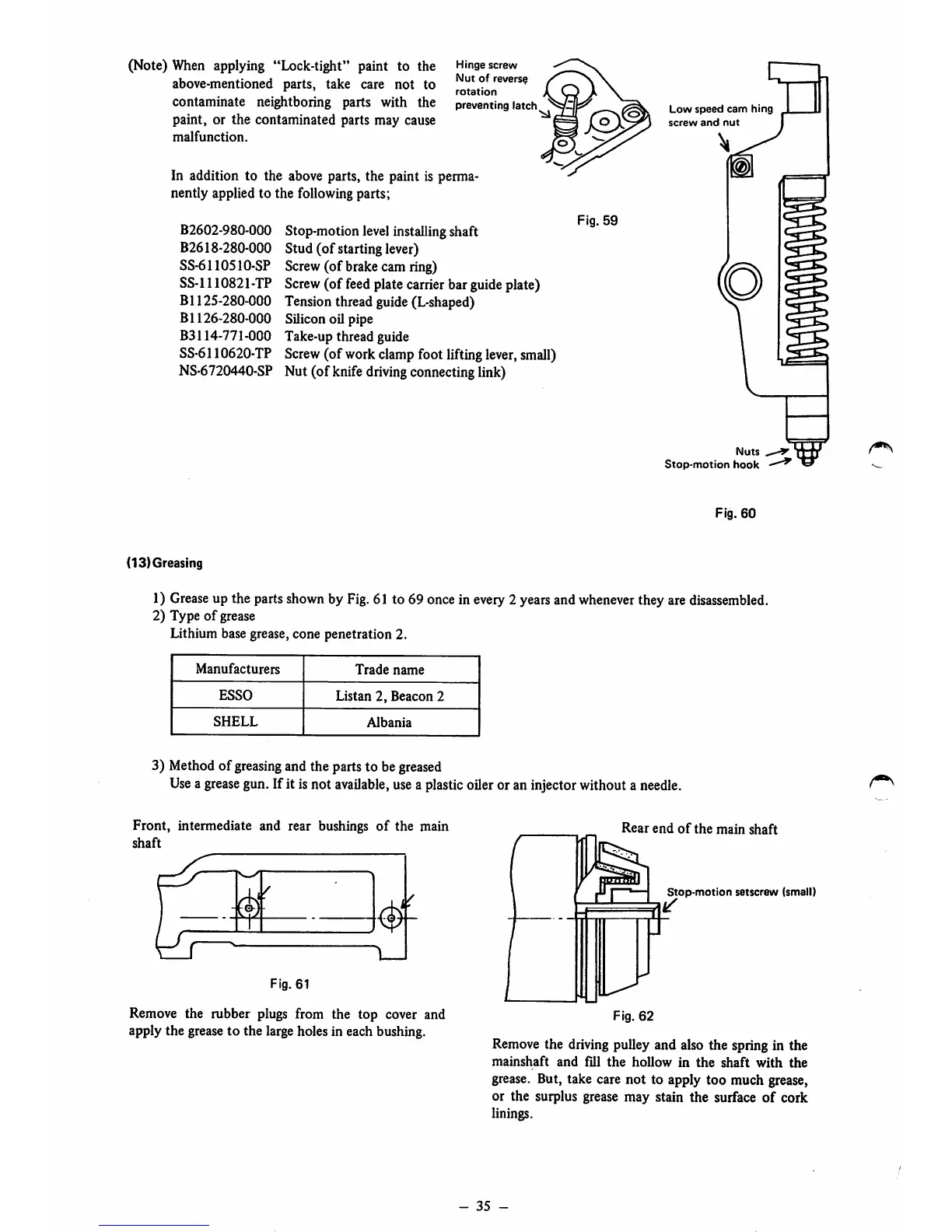

Front, intermediate and rear bushings

of

the main

shaft

Fig. 61

Remove the rubber plugs from the top cover and

apply the grease to the large holes in each bushing.

Rear

end

of

the

main

shaft

Stop-motion

setscrew

(small)

Fig.

62

Remove the driving pulley and also the spring in the

mainshaft

and

fill

the

hollow

in

the

shaft

with

the

grease. But, take care not to apply too much grease,

or the surplus grease may stain the surface

of

cork

linings.

-

35

-

Loading...

Loading...