V.

DETAILS

OF

ADJUSTMENT

(1) Adjustmentfor starting&stopping (Clutch and Stop-motion

mechanism)

(1) Method of adjustment

1)

When

the

machine

will

not run at a highspeed ;

A. Mechanical friction is

too

great.

If

excessive

friction

is

produced

by

tight

engagement

of

the

worm

gears

or

other

parts,

the

important

parts

in

the

machine

including

the cork

linings

will

beheatedup and wornout. Guard

against

excessive

friction.

B. The

driving

pulley

pressing

plate doesnot work properly.

In

this

case,

the

driving

pulley

will

slip

and

will

not

drive

the

machine

at a

high

speed.

Adjust

it

according

to

standard adjustment (6).

C. The stop-motion connecting pin is not properly adjusted.

The

machine

will

not run at a low

speed,

if the

idling

period

of the

brake

cork

ring

is

longer

than that of the

standard period stipulated in standard adjustment (7).

D.

If

stop-motion

ball

® ,

shown

in

the

Structural

Drawing

of

the

Clutch

Component

(p.

26),

accidentally

comes

away

from

the

main

shaft,

the

clutch

surface

can

notbe

aligned

properly.

Therefore,

prevent

the

ball

from fallingby applying

grease

to the main shaft beforehand.

2) When the machine fails to

start:

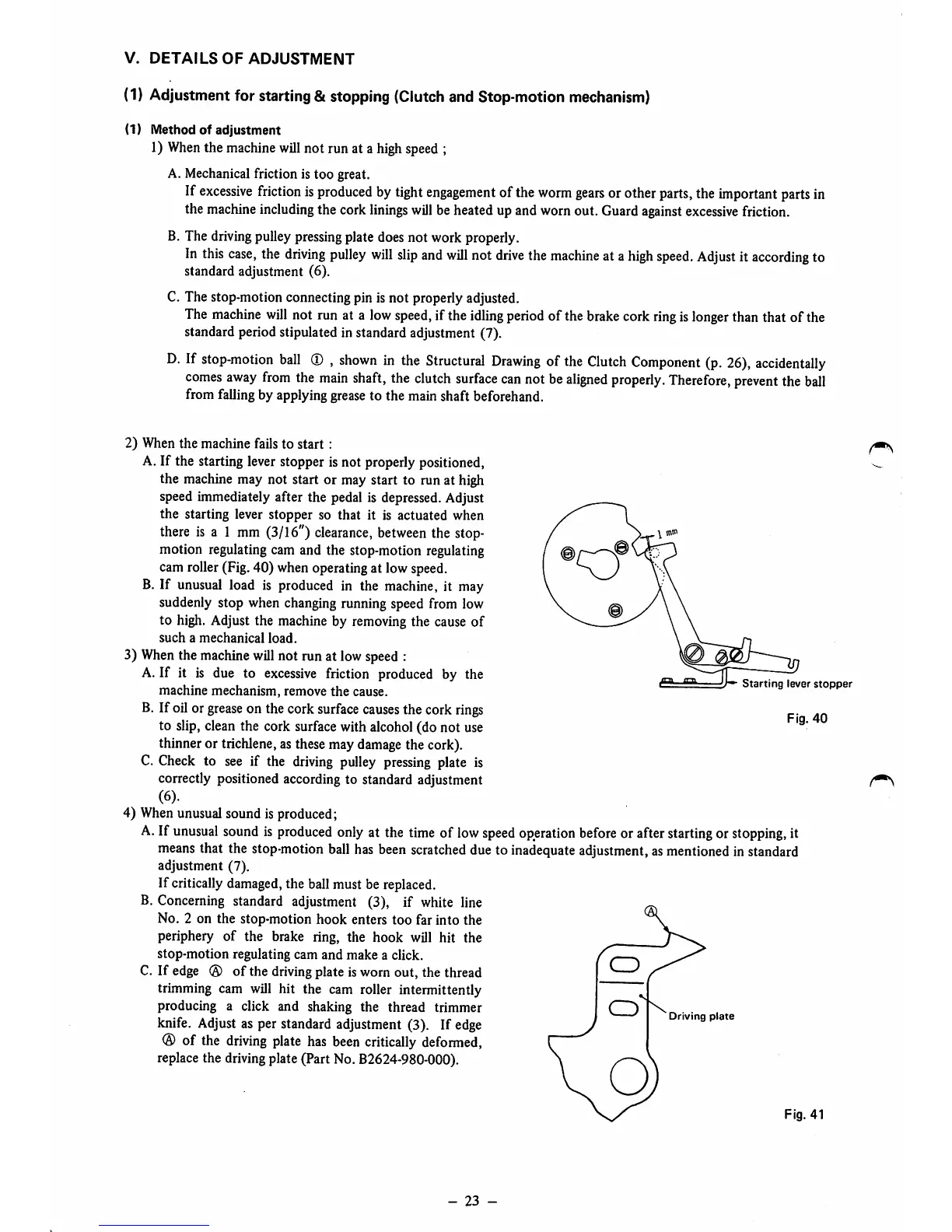

A. If the starting

lever

stopper isnot properlypositioned,

the machine may not start or may start to run at high

speed immediatelyafter the pedal is depressed. Adjust

the starting lever stopper so that it is actuated when

there

is a 1

mm

(3/16")

clearance,

between

the

stop-

motion regulating cam and the stop-motion regulating

cam roller(Fig. 40) whenoperatingat low speed.

B. If

unusual

load is produced in the machine, it may

suddenly stop when changing running speed from low

to high. Adjust the machine by

removing

the cause of

such

a

mechanical

load.

3)

When

the

machine

will

not run at lowspeed :

A. If it is due to

excessive

friction produced by the

machine mechanism, remove

the

cause.

B. If oilor

grease

on the cork

surface

causes

the cork

rings

to slip, clean the cork surfacewith alcohol (do not use

thinneror trichlene, as thesemay

damage

the cork).

C.

Check

to see if the

driving

pulley

pressing

plate is

correctly positioned accordingto standard adjustment

(6).

4) Whenunusual sound is produced;

A.If

unusual

sound

is

produced

only

at the

time

of

low

speed

operation

before

or after

starting

or

stopping,

it

means

that the stop-motion

ball

has

been

scratched

dueto inadequate adjustment, as

mentioned

instandard

adjustment (7).

If critically

damaged,

the ballmust be replaced.

B.

Concerning

standard adjustment (3), if white line

No. 2 on the stop-motion

hook

enters too far into the

periphery of the brake ring, the hook will hit the

stop-motion regulating cam and make a click.

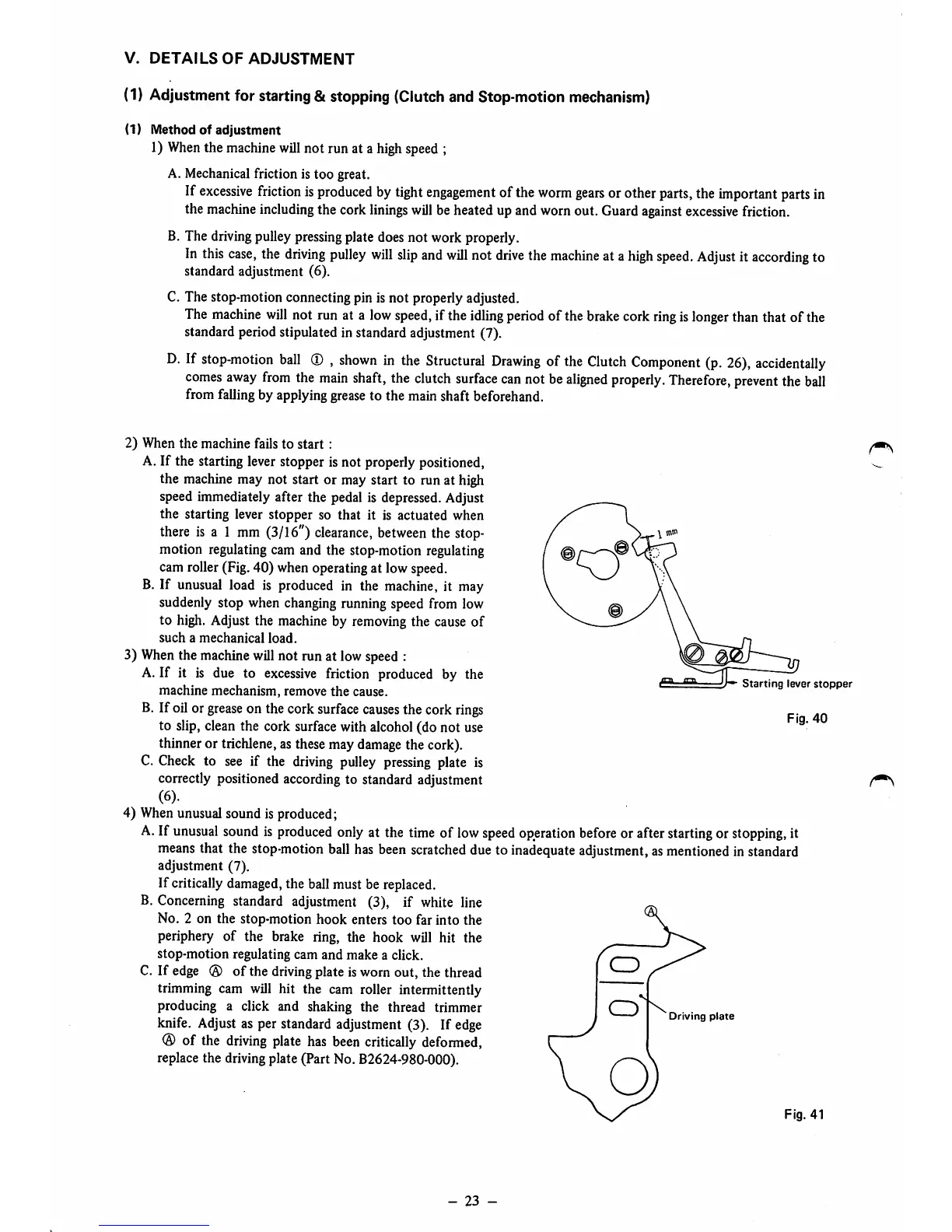

C. If edge ® of the

driving

plate isworn out, the thread

trimming cam will hit the cam roller intermittently

producing a click and shaking the thread trimmer

knife.

Adjust

as per standard adjustment (3). If

edge

(3)

of the

driving

plate

has

been

critically

deformed,

replace

the

driving

plate(Part No.B2624-980-000).

-

23

-

Driving

plate

o

Starting

lever

stopper

Fig.

40

Fig. 41

Loading...

Loading...