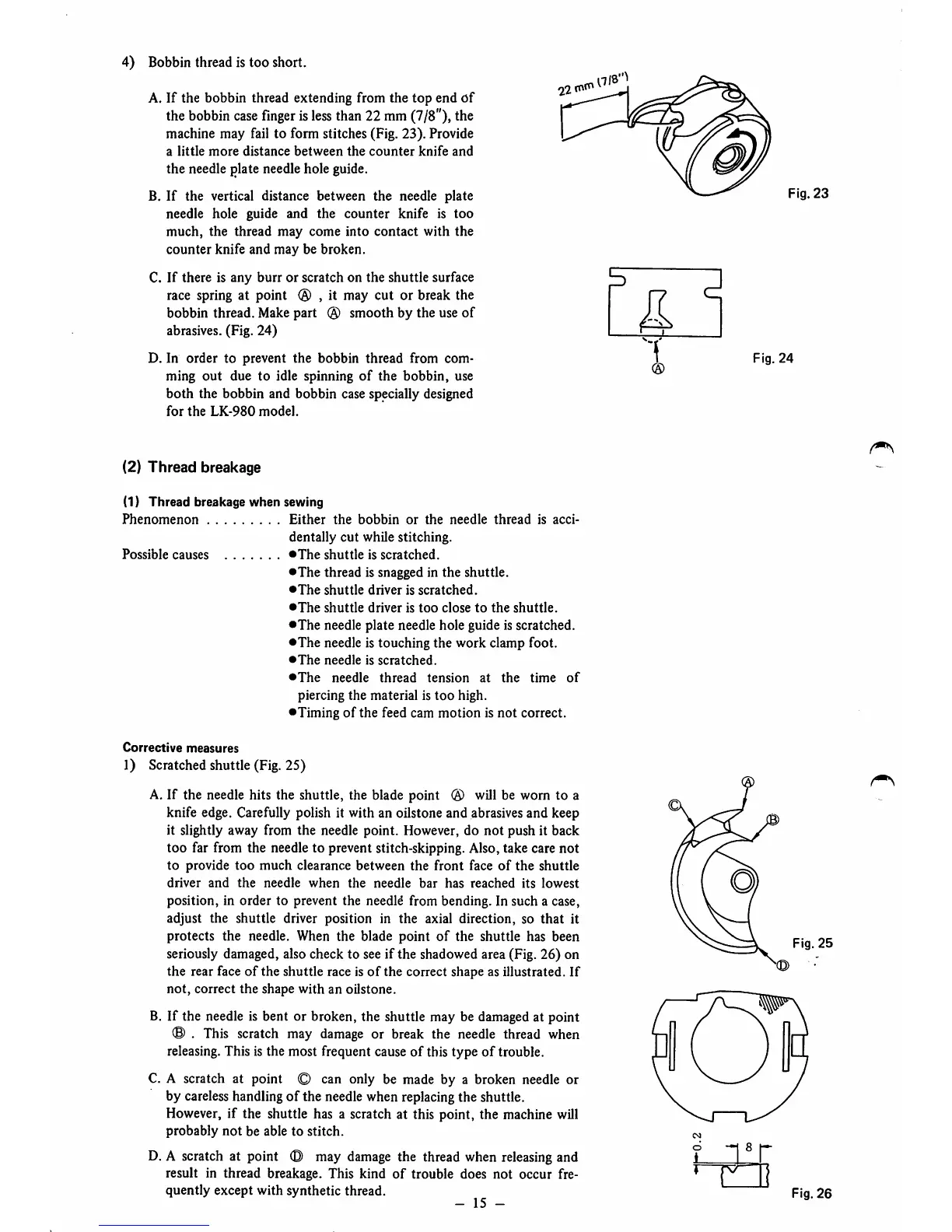

4) Bobbin thread is too short.

A. If the bobbin thread extending from the

top

end

of

the

bobbin

case

finger

is

less

than22 mm(7/8"), the

machine may fail to form stitches (Fig. 23). Provide

a

little

more

distance

between

the

counter

knife

and

the needleplate needlehole

guide.

B.

If

the vertical distance between

the

needle plate

needle hole guide and the

counter

knife is

too

much,

the

thread

may

come

into

contact

with

the

counter

knife

and

may

be

broken.

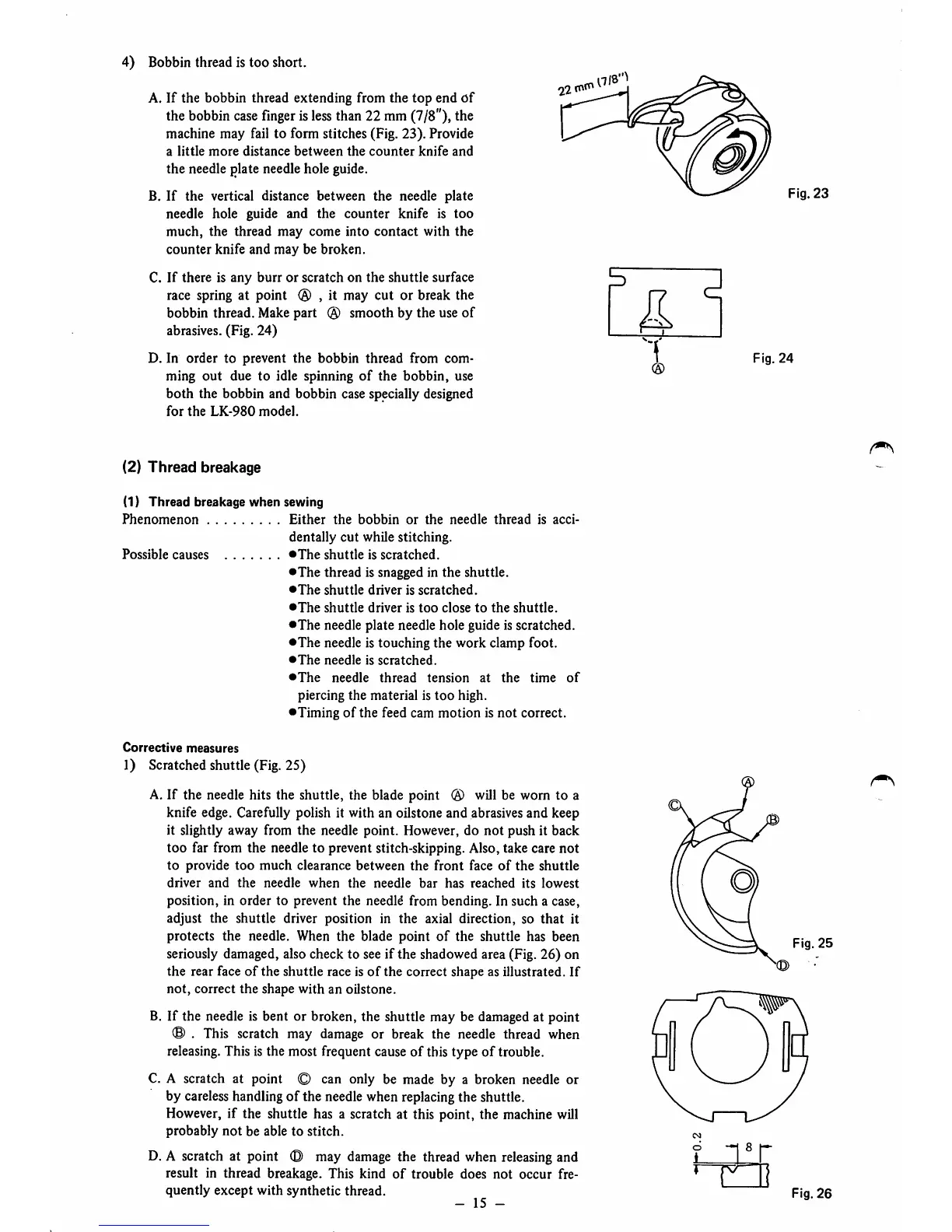

C. If there is any burr or scratch on the shuttle surface

race spring at point

(§)

, it may cut or break the

bobbin thread. Make

part

(g)

smooth by the use

of

abrasives. (Fig. 24)

D. In

order

to prevent

the

bobbin

thread

from com-

ming

out

due to idle spinning

of

the bobbin, use

both

the

bobbin

and bobbin case specially designed

for

the

LK-980

model.

(2) Thread breakage

(1) Thread breakage when sewing

Phenomenon

Either

the

bobbin

or

the

needle

thread

is

acci

dentally

cut

while stitching.

Possible

causes

•The

shuttle

is

scratched.

•The

thread

is snagged in

the

shuttle.

•The

shuttle

driver

is

scratched.

•The

shuttle

driver

is

too

close

to

the

shuttle.

•The

needle plate needle hole guide is scratched.

•The

needle is touching

the

work

clamp foot.

•The

needle

is

scratched.

•The

needle

thread

tension

at

the

time

of

piercing

the

material

is

too

high.

•Timing

of

the feed cam

motion

is

not

correct.

Corrective

measures

1) Scratched shuttle (Fig. 25)

A. If the needle hits the shuttle, the blade point ® will be worn to a

knife edge. Carefully polish it with an oilstone and abrasives and keep

it slightly away from the needle point. However, do

not

push it back

too far from the needle to prevent stitch-skipping. Also, take care not

to provide

too

much clearance between

the

front face

of

the

shuttle

driver

and

the

needle

when

the

needle

bar

has

reached

its

lowest

position, in

order

to prevent the needld from bending. In such a case,

adjust the shuttle driver position in

the

axial direction, so

that

it

protects the needle. When the blade

point

of

the shuttle has been

seriously damaged, also check to see if the shadowed area (Fig. 26) on

the

rear face

of

the shuttle race is

of

the correct shape as illustrated.

If

not,

correct the shape with an oilstone.

B. If the needle is bent or broken, the shuttle may be damaged at point

® . This scratch may

damage

or break the needle thread when

releasing. This is the most frequent cause

of

this type

of

trouble.

C. A scratch at point © can only be made by a broken needle or

by carelesshandling

of

the needle when replacing the shuttle.

However, if the shuttle has a scratch at this point, the machine will

probably

not

be able to

stitch.

D. A scratch at point © may

damage

the thread when

releasing

and

result in thread breakage. This kind

of

trouble does

not

occur fre

quently except with synthetic thread.

s

(S>

Fig.

23

Fig.

24

Fig.

25

rr

Fig.

26

Loading...

Loading...