-

27

-

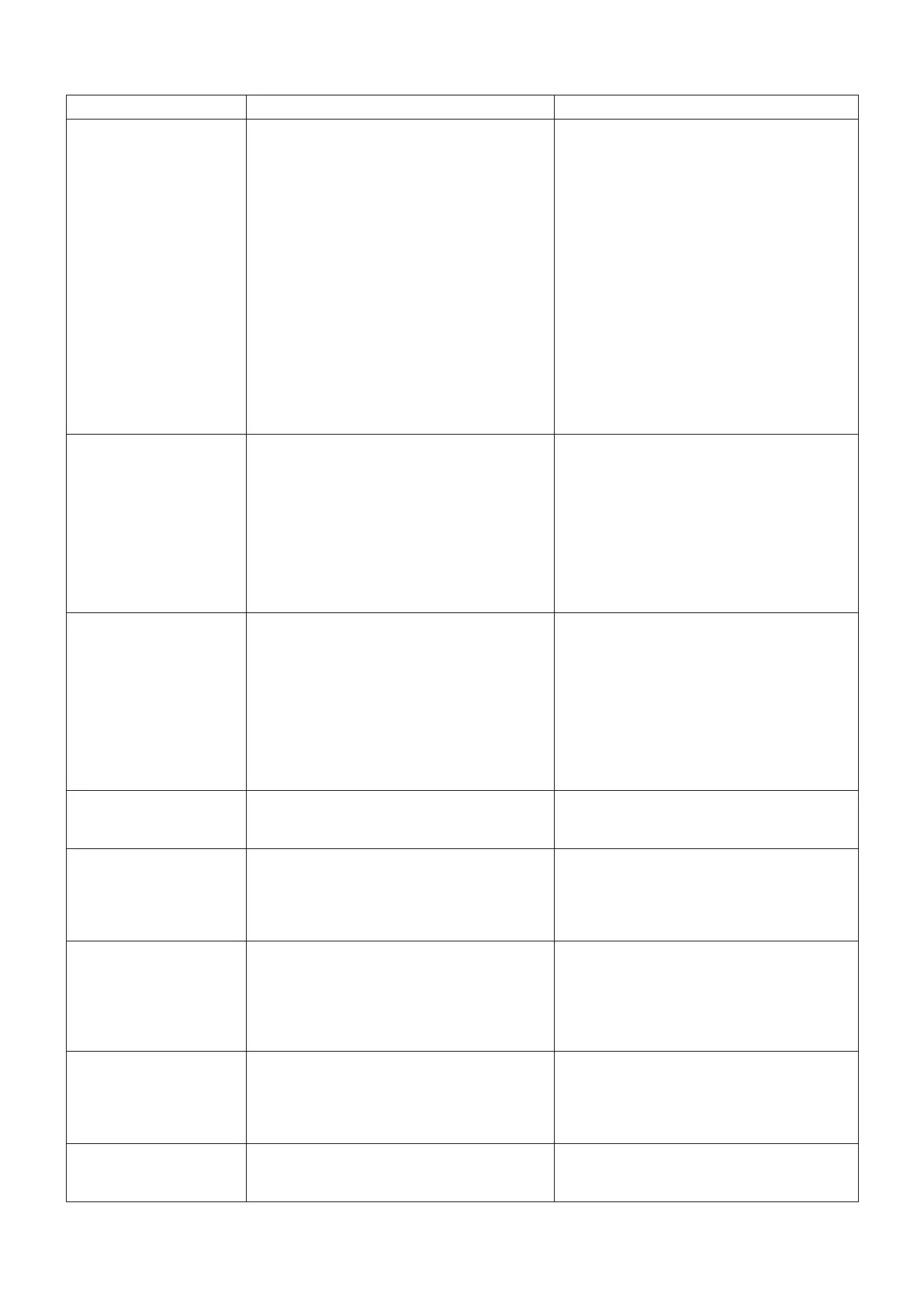

29. TROUBLES IN SEWING AND CORRECTIVE MEASURES

Troubles Causes Corrective measures

1. Thread breakage

(Thread frays or is worn

out.)

(Needle thread trails 2 to

3 cm from the wrong side

of the fabric.)

Thread path, needle point, hook blade point or

bobbin case resting groove on the throat plate has

sharp edges or burrs.

Needle thread tension is too high.

Bobbin case opening lever provides an excessive

clearance at the bobbin case.

Needle comes in contact with the blade point of

hook.

Amount of oil in the hook is too small.

Needle thread tension is too low.

Thread take-up spring works excessively or the

stroke of the spring is too small.

Timing between the needle and the hook is exces-

sively advanced or retarded.

Remove the sharp edges or burrs on the blade

point of hook using a fine emery paper. Buff up

the bobbin case resting groove on the throat plate.

Decrease the needle thread tension.

Decrease the clearance provided between the

bobbin case opening lever and the bobbin. Refer

to “22. ADJUSTING THE BOBBIN CASE OPEN-

ING LEVER.”

Refer to “20. NEEDLE-TO-HOOK RELATION.”

Adjust the amount of oil in the hook properly. See

“13. ADJUSTING THE AMOUNT OF OIL IN THE

HOOK.”

Increase the needle thread tension.

Decrease the tension of the spring and increase

the stroke of the spring.

Refer to “20. NEEDLE-TO-HOOK RELATION.”

2. Stitch skipping

Timing between the needle and the hook is exces-

sively advanced or retarded.

Pressure of the presser foot is too low.

The clearance provided between the top end of

the needle eyelet and the blade point of hook is

not correct.

Hook needle guard is not functional.

Improper type of needle is used

Refer to “20. NEEDLE-TO-HOOK RELATION.”

Tighten the presser spring regulator.

Refer to “20. NEEDLE-TO-HOOK RELATION.”

Refer to “21. ADJUSTING THE HOOK NEEDLE

GUARD.”

Replace the needle with one which is thicker than

the current needle by one count.

3. Loose stitches

Bobbin thread does not pass through the tension

spring of the inner hook.

Threadpathhasbeenpoorlynished.

Bobbin fails to move smoothly.

Bobbin case opening lever provides too much

clearance at the bobbin.

Bobbin thread tension is too low.

Bobbin has been wound too tightly.

Thread the bobbin thread correctly.

Removeroughpartswithaneemerypaperor

buff it up.

Replace the bobbin or hook with a new one.

Refer to “22. ADJUSTING THE BOBBIN CASE

OPENING LEVER.”

Increase the bobbin thread tension.

Decrease the tension applied to the bobbin wind-

er.

4. Thread slips off the needle

eyelet simultaneously with

thread trimming.

Thread tension given by the tension controller No.

1 is too high.

Decrease the thread tension given by the tension

controller No. 1.

5. Thread slips off the needle

eyelet at the start of sew-

ing.

Thread tension given by the tension controller No.

1 is too high.

Clamp spring has improper shape.

Bobbin thread tension is too low.

Decrease the thread tension given by the tension

controller No. 1.

Replace the clamp spring with a new one or

correct the current one.

Increase the bobbin thread tension.

6. Thread is not cut sharply.

The blades of moving knife and counter knife have

been improperly adjusted.

The knives have blunt blades.

Bobbin thread tension is too low.

Refer to “23. POSITION OF THE COUNTER

KNIFE AND ADJUSTMENT OF THE KNIFE

PRESSURE.”

Replace the moving knife and counter knife with

new ones, or correct the current ones.

Increase the bobbin thread tension.

7. Thread remains uncut

after thread trimming.

(Bobbin thread trimming

failure when stitch length

is comparatively short.)

Initial position of the moving knife has been im-

properly adjusted.

Bobbin thread tension is too low.

Refer to “Adjusting the initial position of the knife”

in the Engineer’s Manual.

Increase the bobbin thread tension.

8. Thread breaks at the start

of sewing after thread

trimming.

The needle thread is caught in the hook. Shorten the length of thread remaining on the nee-

dle after thread trimming. Refer to “16. THREAD

TENSION.”