SEWING MACHINE DIV.20 MODEL 385. 17822490

NEEDLESWING

MECHANICAL ADJUSTMENT

TO CHECK:

IF THE NEEDLE BAR MOVES SIDEWISE WHILE THE NEEDLE IS IN THE FABRIC IN ZIGZAG

STITCHING, ADJUST IN AS FOLLOWS:

(THE NEEDLE SHOULD STARTSWINGING WHEN 2 TO 3MM ABOVE THE NEEDLE PLATE.)

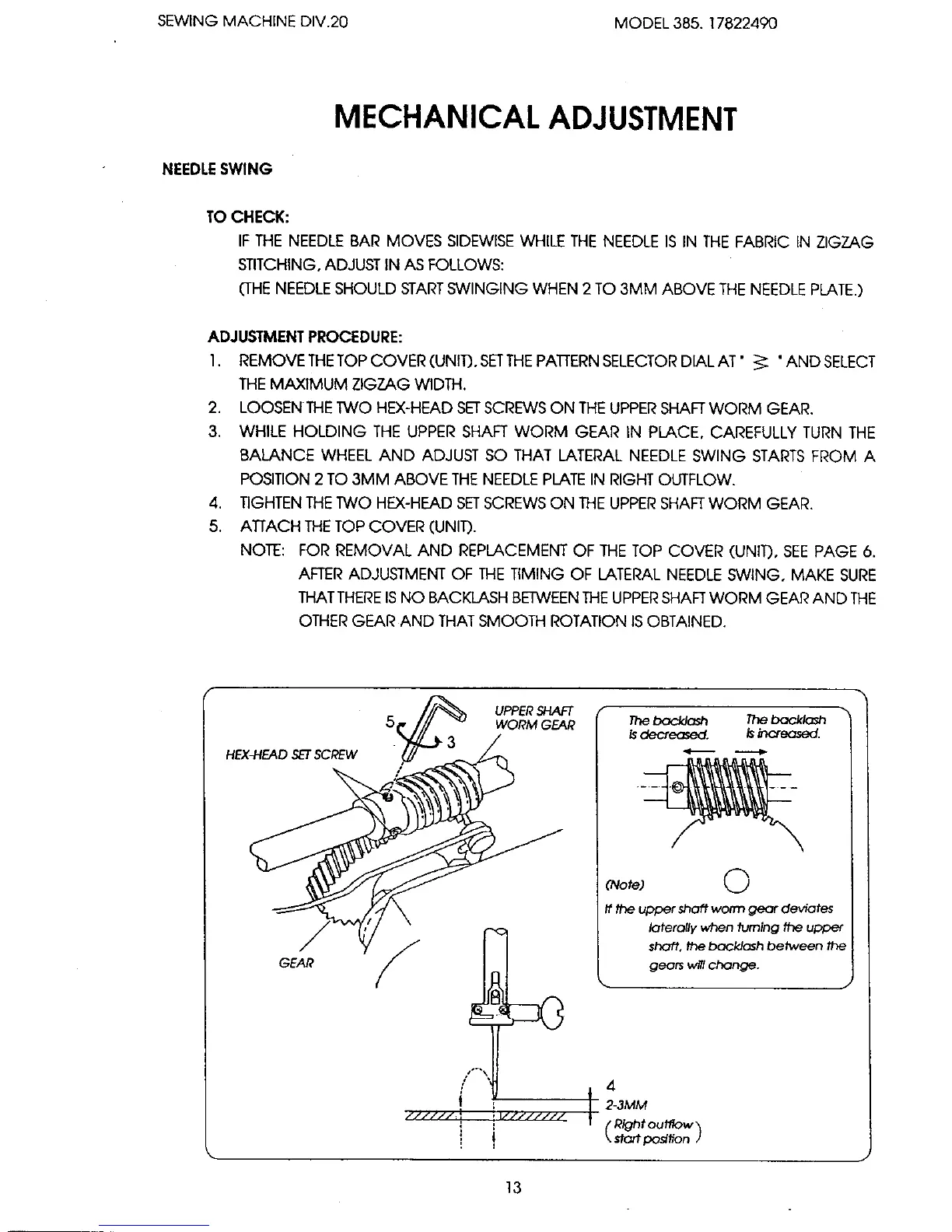

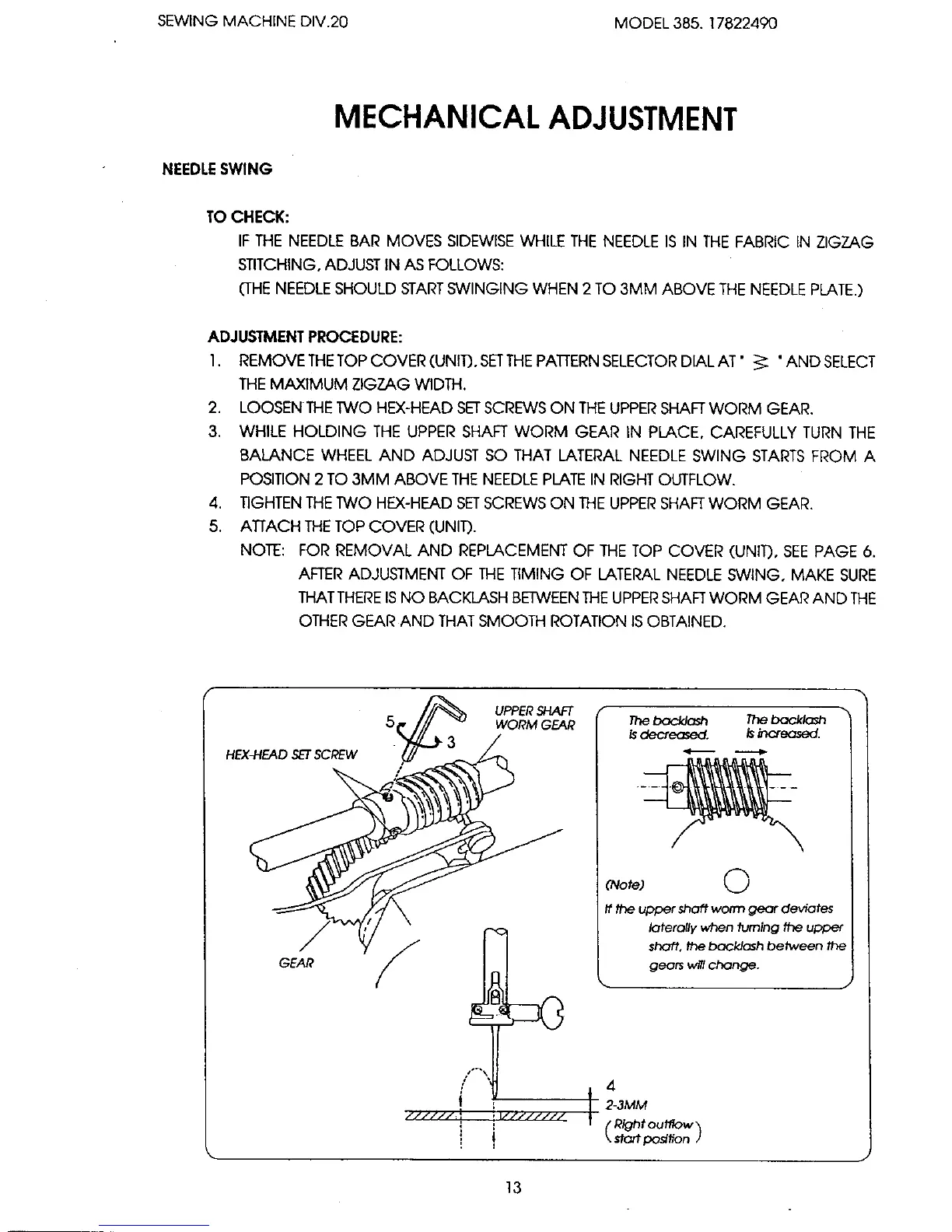

ADJUSTMENT PROCEDURE:

1. REMOVETHETOPCOVER(UNIT),SETTHEPAI"I"ERNSELECTORDIALAT" _ "ANDSELECT

THE MAXIMUM ZIGZAG WIDTH.

2. LOOSEN THE TWO HEX-HEAD SETSCREWS ON THE UPPERSHAFTWORM GEAR.

3. WHILE HOLDING THE UPPER SHAFT WORM GEAR IN PLACE, CAREFULLY TURN THE

BALANCE WHEEL AND ADJUST SO THAT LATERAL NEEDLE SWING STARTS FROM A

POSITION 2 TO 3MM ABOVE THE NEEDLE PLATEIN RIGHT OUTFLOW.

4. TIGHTEN THETWO HEX-HEAD SETSCREWS ON THE UPPERSHAFT WORM GEAR.

5. AI_ACH THE TOP COVER (UNIT).

NOTE: FOR REMOVAL AND REPLACEMENT OF THE TOP COVER (UNIT), SEE PAGE 6.

AFTER ADJUSTMENT OF THE TIMING OF LATERAL NEEDLE SWING, MAKE SURE

THATTHEREISNO BACKLASH BETWEENTHEUPPERSHAFT WORM GEAR AND THE

OTHER GEAR AND THAT SMOOTH ROTATION ISOBTAINED.

HEX-HEADSETSCREW

GEAR

,_3 UPPER SHAFT

5 WORM GEAR

/

lhe bocklash Thebacklash

Isdecreased, isincreased.

(Note) 0

ff the uppershaft wormgear deviates

Ioterallywhen fuming the uppe

shaft,thebocldosh between the

geors willchange.

I 24_3MM

( Rightoutflow_

\ sta_"t pos_fion )

13

Loading...

Loading...