SEWINGMACHINEDIV.20 MODEL385.17822490

MECHANICAL ADJUSTMENT

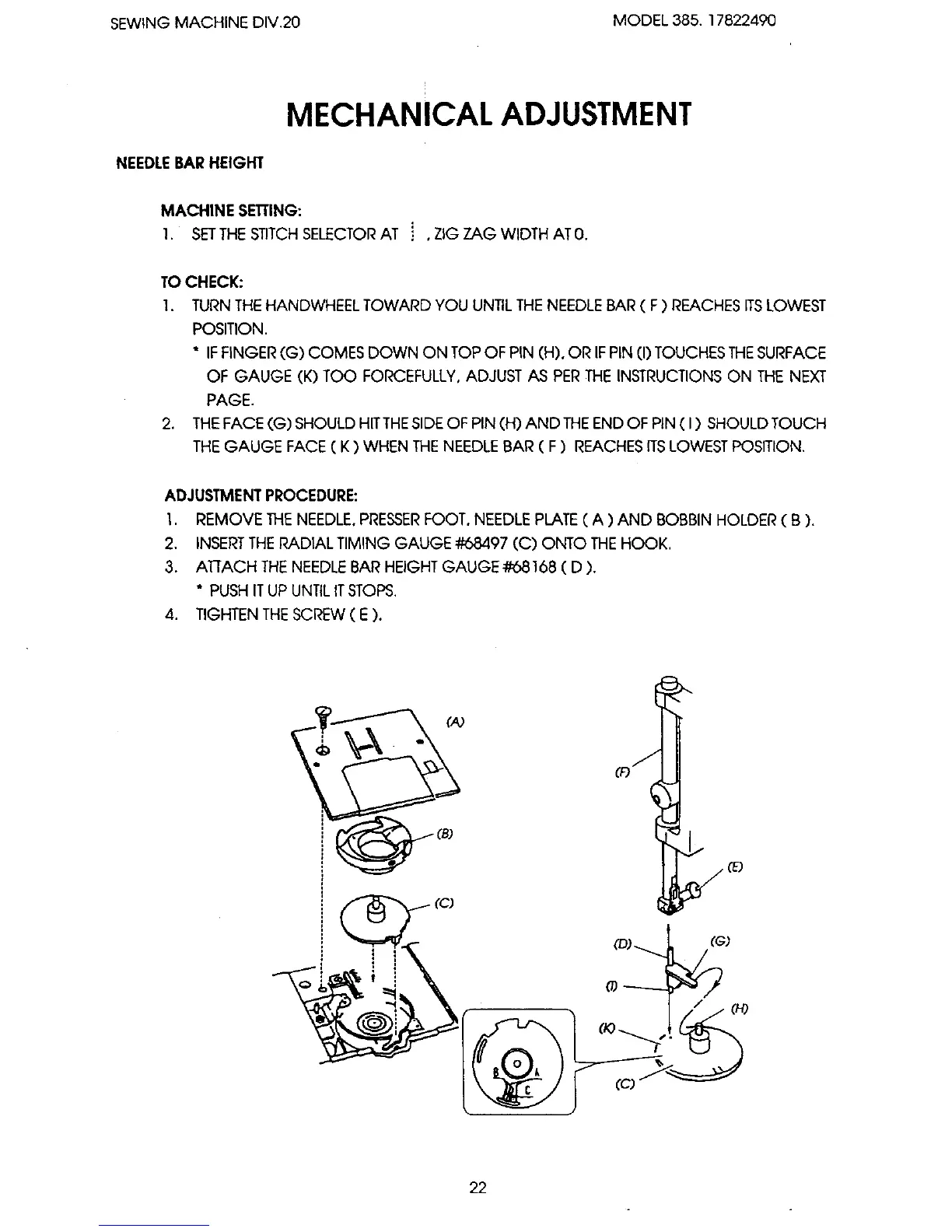

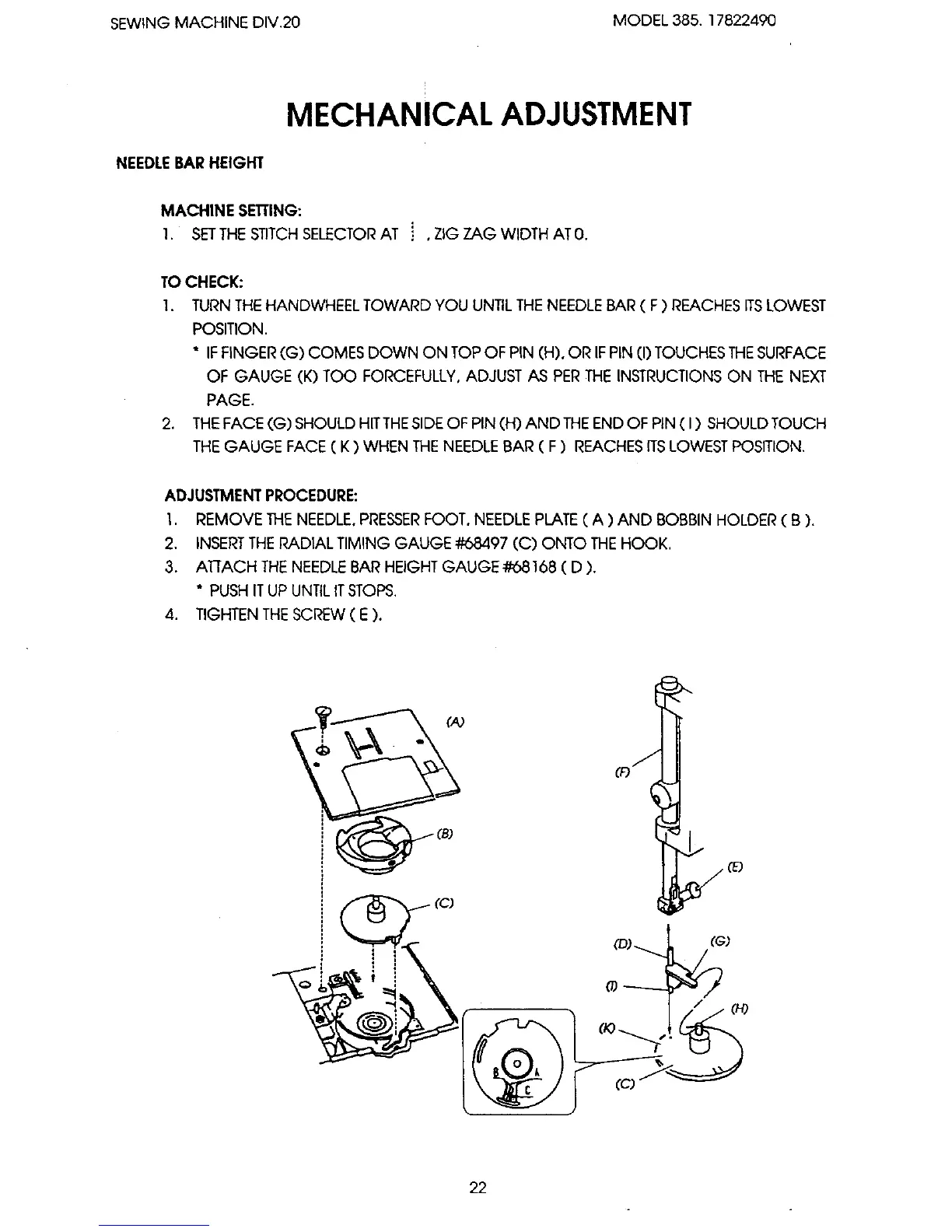

NEEDLEBAR HEIGHT

MACHINE SETTING:

1. SETTHE STITCHSELECTORAT _ , ZIG ZAG WIDTH AT 0.

TO CHECK:

1. TURN THEHANDWHEEL TOWARD YOU UNTILTHE NEEDLE BAR ( F) REACHES ITSLOWEST

POSITION.

* IFFINGER (G) COMES DOWN ON TOP OF PIN (H), OR IFPiN [I) TOUCHES THESURFACE

OF GAUGE (IO TOO FORCEFULLY, ADJUST AS PER THE INSTRUCTIONS ON THE NEXT

PAGE.

2. THE FACE (G) SHOULD HITTHESIDE OF PIN (H) AND THEEND OF PIN ( I ) SHOULD TOUCH

THE GAUGE FACE ( K ) WHEN THE NEEDLE BAR ( F) REACHES ITSLOWEST POSITION.

ADJUSTMENT PROCEDURE:

1. REMOVE THE NEEDLE. PRESSERFOOT. NEEDLE PLATE ( A ) AND BOBBIN HOLDER ( B ).

2. INSERTTHE RADIAL TIMING GAUGE :#68497 (C) ONTO THE HOOK,

3. AI-[ACH THENEEDLE BAR HEIGHT GAUGE :#_58168[ D ).

* PUSH ITUP UNTILITSTOPS.

4. TIGHTEN THE SCREW ( E ).

(A)

(c)

(c)

(G)

22

Loading...

Loading...