TP-6805 8/15 23Section 2 Scheduled Maintenance

e. Clean the area around the dipstick and oil fill

cap.

f. Remove the cap from the oil drain hose and

lower the hose into an oil collection container.

g. Open the oil drain valve on the engine.

h. Remove the dipstick and oil fill cap. Allow time

for the engine oil to drain completely.

i. Close the oil drain valve. Replace the cap on

the oil drain hose. Replace the oil drain hose in

its retaining clip.

j. Replace the dipstick.

2. Replace the oil filter.

a. Clean the area around the oil filter. Remove the

oil filter by rotating it counterclockwise with an

oil filter wrench.

b. Clean the gasket sealing surface of the oil filter

adapter.

c. Apply a light coat of clean oil to the rubber seal

of the new oil filter.

d. Install the new oil filter following the instructions

provided with the filter.

3. Fill with oil.

a. Fill the engine to the F mark on the dipstick.

Section 2.2.3, Engine Oil Recommendation,

for oil selection. See Figure 2-3 for the engine

oil capacity.

b. Reinstall the dipstick and the oil fill cap.

c. Reconnect the generator set engine starting

battery, negative (--) lead last.

d. Reconnect utility power to the generator set.

e. Press the RUN button to start and run the

generator set for a minute to allow the oil

pressure to reach operating range.

f. Stop the generator set, wait 1 minute, and then

recheck the oil level. Add oil to bring the level

up to the F mark on the dipstick.

4. Check for leaks.

a. Check for oil leaks.

b. Fix leaks and recheck the oil level.

c. Reinstall the housing side panel.

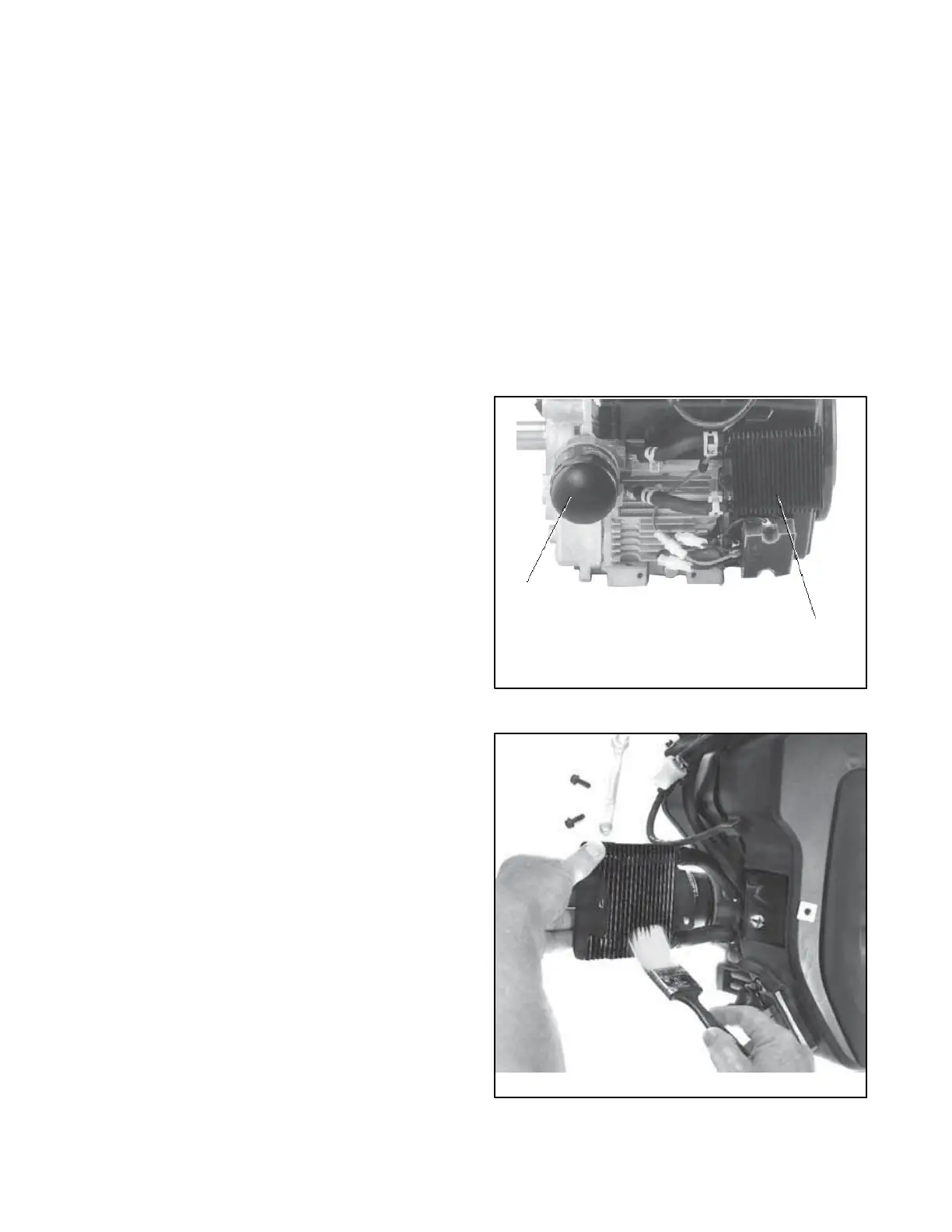

2.2.5 Oil Cool er, 14kW Mo dels

Inspect and clean the oil cooler at the intervals shown in

the Service Schedule. The oil cooler must be kept free

of debris.

Remove the front enclosure panel to access the oil

cooler. See Section 7.2 for instructions to remove the

front panel.

See Figure 2-4 for the oil cooler location. Clean the

outside of the oil cooler with a brush or compressed air.

If it is necessary to clean the back of the oil cooler,

remove the two screws holding the oil cooler unit to the

blower housing. Tilt the cooler and clean with a brush or

compressed air as shown in Figure 2-5. After cleaning,

reinstall the oil cooler and secure with the mounting

screws.

2

24 590 01 -- A

1. Oil filter

2. Oil cooler

1

Figure 2-4 Oil Cooler Location, 14 kW Models

24 590 01 -- A

Figure 2-5 Cleaning the Oil Cooler