TP-6805 8/1594 Section 6 Component Testing and Adjustment

6.2 Alternator Excitation

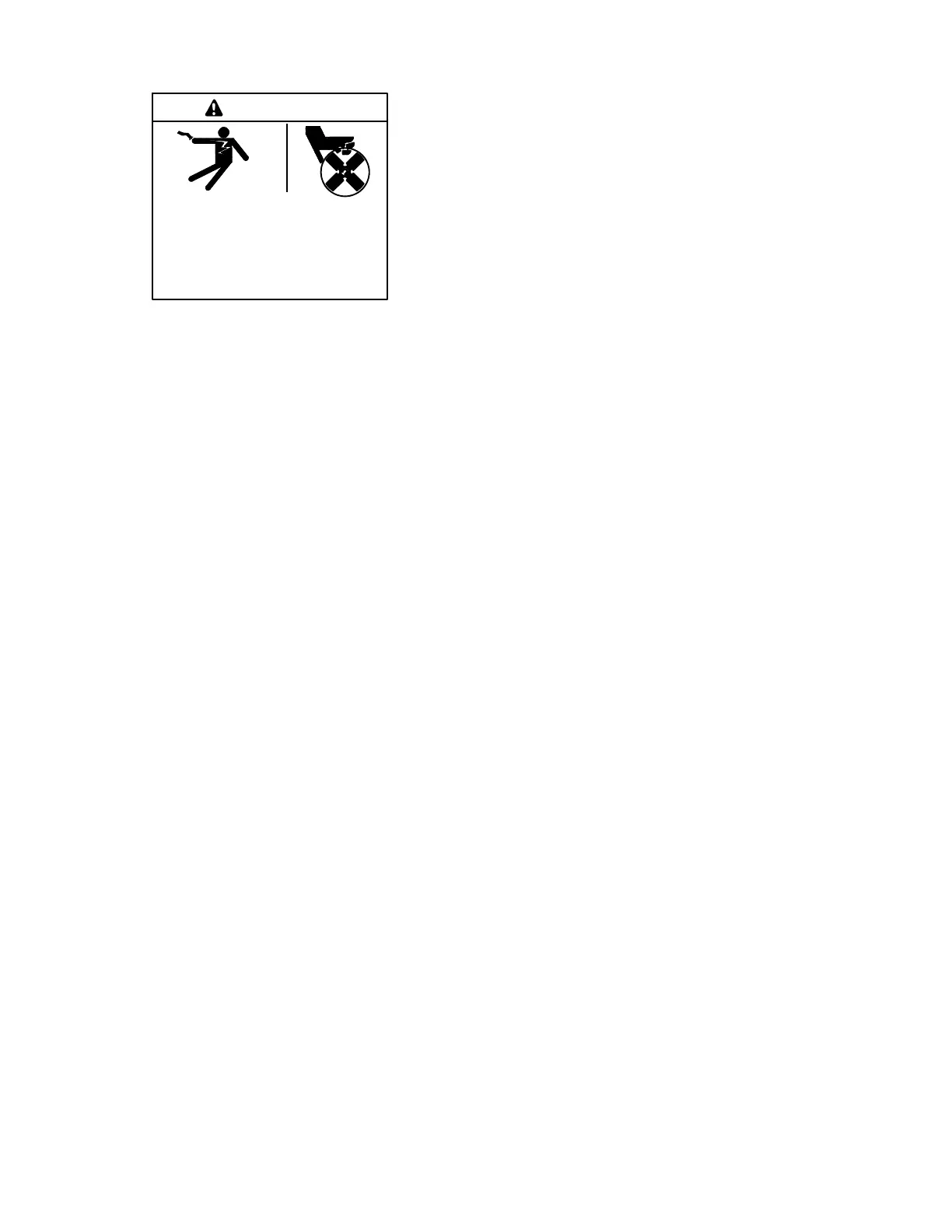

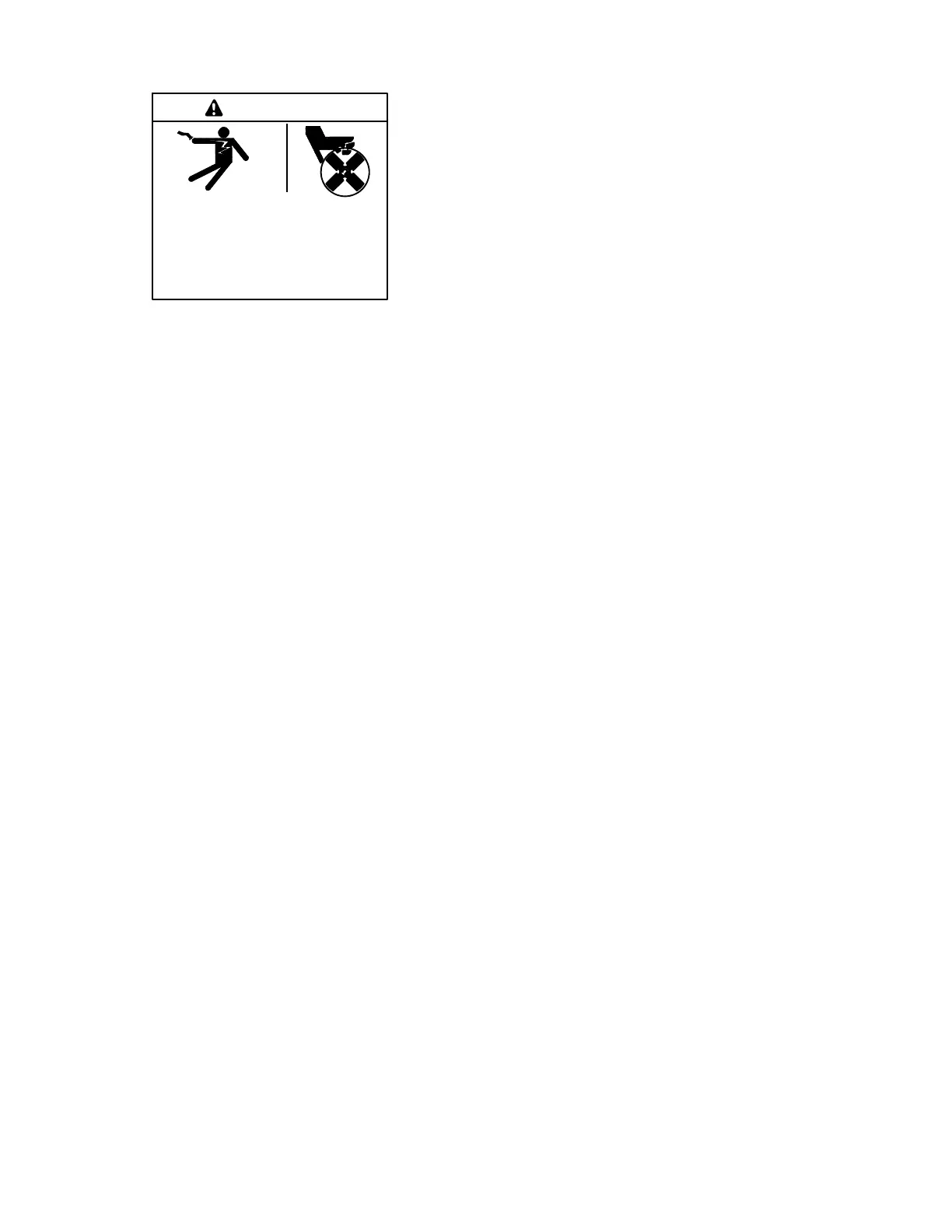

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving parts.

WARNING

Testing live electrical circuits. Hazardous voltage or

current can cause severe injury or death. Have trained and

qualified personnel take diagnostic measurements of live

circuits. Use adequately rated test equipment with electrically

insulated probes and follow the instructions of the test

equipment manufacturer when performing voltage tests.

Observe the following precautions when performing voltage

tests: (1) Remove all jewelry. (2) Stand on a dry, approved

electrically insulated mat. (3) Do not touch the enclosure or

components inside the enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

6.2.1 No to Low Voltage Operation

This section covers the operation of the alternator

excitation and troubleshooting information for low or no

voltage output.

Before beginning the test procedures, read all safety

precautions at the beginning of this manual. Many of the

test procedures include additional safety precautions.

After crank disconnect, controller will disengage the

flash relay when the AC output of the generator reaches

1/4 of the output voltage. At this level, the output on the

auxiliary windings should have reached a level sufficient

to self-excite the alternator rotor field. If the output

voltage does not exceed 1/3 of rated voltage, the

generator is only producing voltage using the flash relay.

To further isolate the cause of this failure:

1. Check the condition of the alternator circuit

breaker. The circuit breaker is located in the service

access area on the controller. If this breaker is

open, the auxiliary winding current will not be able

to reach the field and the field will only be supplied

by the flash relay. If the breaker is tripped, stop the

generator, disconnect P2 and verify no continuity

between ground and each of 55, 66, FP, FN.

2. Verify the connections for 55, 55F and 66 per

Figure 6-1.

3. Reconnect P2, start the generator and check for

voltage between 55 and 66. This voltage should

exceed 30 Volts AC when the AC output voltage is

above 60 Volts AC. If the voltage does not exceed

30 VAC, stop the generator and complete the rotor

and stator checks in Sections 6.3 and 6.4.

4. Check DC voltage between FP and FN. If this

voltage is above 20 VDC, stop the generator and

complete the rotor and stator checks in Sections

6.3 and 6.4.

5. If the auxiliary winding voltage exceeds 30 VAC

and the field voltage does not exceed 20 VDC,

replace the generator controller.

6.2.2 Erratic Voltage Regulation

Dramatic variations in the alternator voltage (more than

5 VAC) while the generator is operating at a steady load

may cause flicker. Connect a flicker lamp to the

generator output to determine if the generator is

producing flicker. If flicker is observed, it can be caused

by any of the following:

D Engine speed fluctuation. Refer to Sections 6.8 and

6.9 for troubleshooting.

D Alternator fault. Refer to Sections 6.3 and 6.4 for

troubleshooting.

D Outer loop gain too high. Refer to Section 6.7.

D Internal controller stability circuit failure, indicated by

excessive throttle movement, excessive voltage

fluctuation, and dramatic flicker.

6.2.3 Separate Excitation

Use the following procedure to separately excite the

generator using an external voltage source (a 12-volt

automotive battery).

Separately exciting the generator can identify faulty

voltage regulation by the controller or reveal a running

fault in the rotor and/or stator. An external power source

duplicates the role o f the voltage regulator and excites

the generator field (rotor). A generator component that

appears to be in good condition while stationary may

exhibit a running fault (open or short circuit) while

moving. Centrifugal forces acting on the windings

during rotation may cause a broken circuit to open.

Increasing temperatures can cause the insulation to

break down, resulting in a running fault. If this test

shows that the rotor and stator are in good condition, test

the voltage regulation using the tests in Section 6.7.

Loading...

Loading...