TP-6519 8/1768 Section 5 Component Testing and Adjustment

Remove the LOP switch and install an oil pressure

gauge to verify that the engine oil pressure is within the

range specified in Section 1, Specifications, before

testing or replacing the LOP switch. To test the LOP

switch, reinstall the switch and start the generator set. If

the unit shuts down, disconnect lead 13 from the LOP

switch and reset the controller. Restart the generator

set and verify that it does not shut down. A successful

restart indicates a faulty LOP switch. Replace switch.

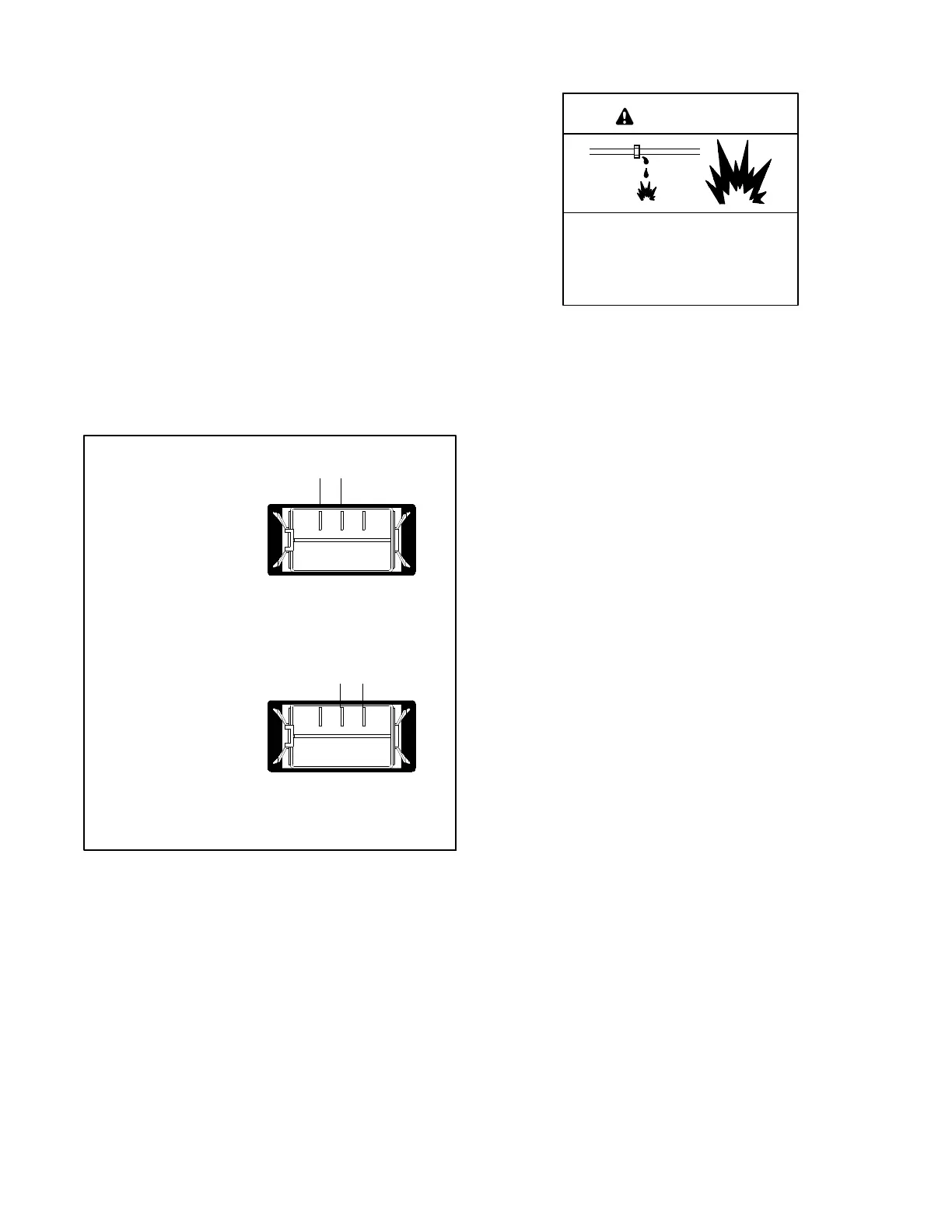

5.11 Generator Set Master Switch

The generator set master switch is a three-position

(RUN\OFF/RESET\AUTO) rocker switch. The leads

connecting to the master switch are labeled RUN,

VBAT, and AUTO. Check that the three connectors are

connected to the terminals on the back of the switch as

shown in Figure 5-31. Be careful not to reverse the

RUN and AUTO leads.

tp6196

Master Switch in

RUN Position

Master Switch in

AUTO Position

Zero ohms (continuity) across

RUN and VBAT terminals

Zero ohms (continuity) across

VBAT and AUTO terminals

AUTO

RUN

VBAT

AUTO

RUN

VBAT

(back view)

Figure 5-31 Generator Set Master Switch Continuity

Checks

5.12 Fuel Systems

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

WARNING

The fuel supplier provides and maintains manual

shut-off valves and the primary regulator. See the

generator set installation manual for fuel pipe size

recommendations. Verify that the fuel system capacity

is adequate to supply the generator set plus all other gas

appliances.

A factory-installed secondary regulator and 12 VDC

solenoid valve are located in the front inlet air

compartment. The controller energizes the fuel

solenoid valve to open at startup and deenergizes the

valve to close at shutdown. The secondary fuel

regulator reduces fuel pressure for delivery to the fuel

block. The fuel flows from the fuel block to the

carburetor in a gaseous state. The carburetor mixes the

fuel with intake air for consumption by the engine.

Refer to the troubleshooting instructions in Section 3,

Troubleshooting, to identify generator set operation

problems that may be caused by an inadequate fuel

supply, incorrect adjustments, or damaged fuel system

components. Then use the instructions in this section to

check fuel system components.

5.12.1 Fuel Solenoid Valve

A solenoid valve upstream of the regulator and the

flexible fuel connector provides automatic fuel on/off

control. The engine starting battery powers the solenoid

valve and the engine starting controls open the valve

when the engine cranks or runs.

Gas Valve Operation Test Procedure

1. Disconnect the positive ( +) battery lead from the

gas valve terminal.

2. Apply 12 VDC to the gas valve terminal and listen

for an audible click, indicating that the valve

actuates.

3. Replace the gas valve if it does not actuate in

step 2.

Loading...

Loading...