184 Section 9 Gas Fuel Systems TP-6356 4/12

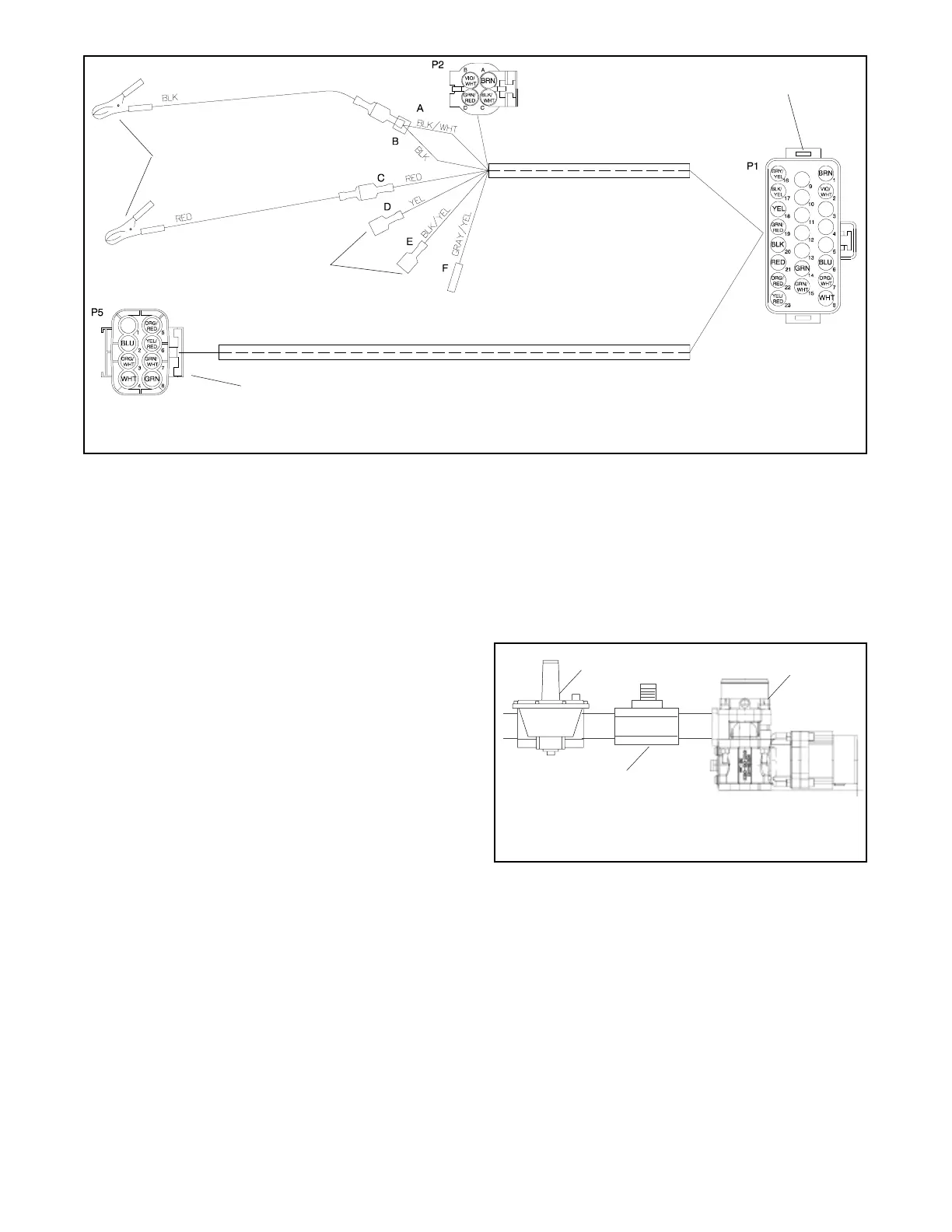

1. Battery power supply connection

2. Digital voltmeter (DVM) connection

3. Air/fuel control module connection

4. Oxygen sensor connection

GM28981-A

1

2

3

4

Figure 9-47 Sensor Interface Harness GM28981 Electrical Connections

c. Place the controller master switch in the RUN

position to start generator set.

d. Allow the generator set to run until the

generator set reaches normal operating

temperature. The time required to reach

normal operating temperature depends

primarily on the ambient temperature and the

size of the engine.

e. With the generator set at normal operating

temperature, apply 90%--100% of rated load. If

a load bank is not available, apply a load at

least comparable to what is generally

connected to the generator set.

f. Verify that the fuel pressure is within

7--11 inches of water at full load. Adjust the

primary fuel regulator as necessary to achieve

the fuel pressure of 7--11 inches of water as

measured at the inlet side of the generator set

fuel solenoid valve.

g. Remove the load and allow the generator set to

run unloaded to cool for at least 5--10 minutes.

h. Place the controller master switch in the OFF

position to stop generator set.

8. Adjust the fuel mixture.

Choose the procedure based on the type of gas

mixer on the generator set.

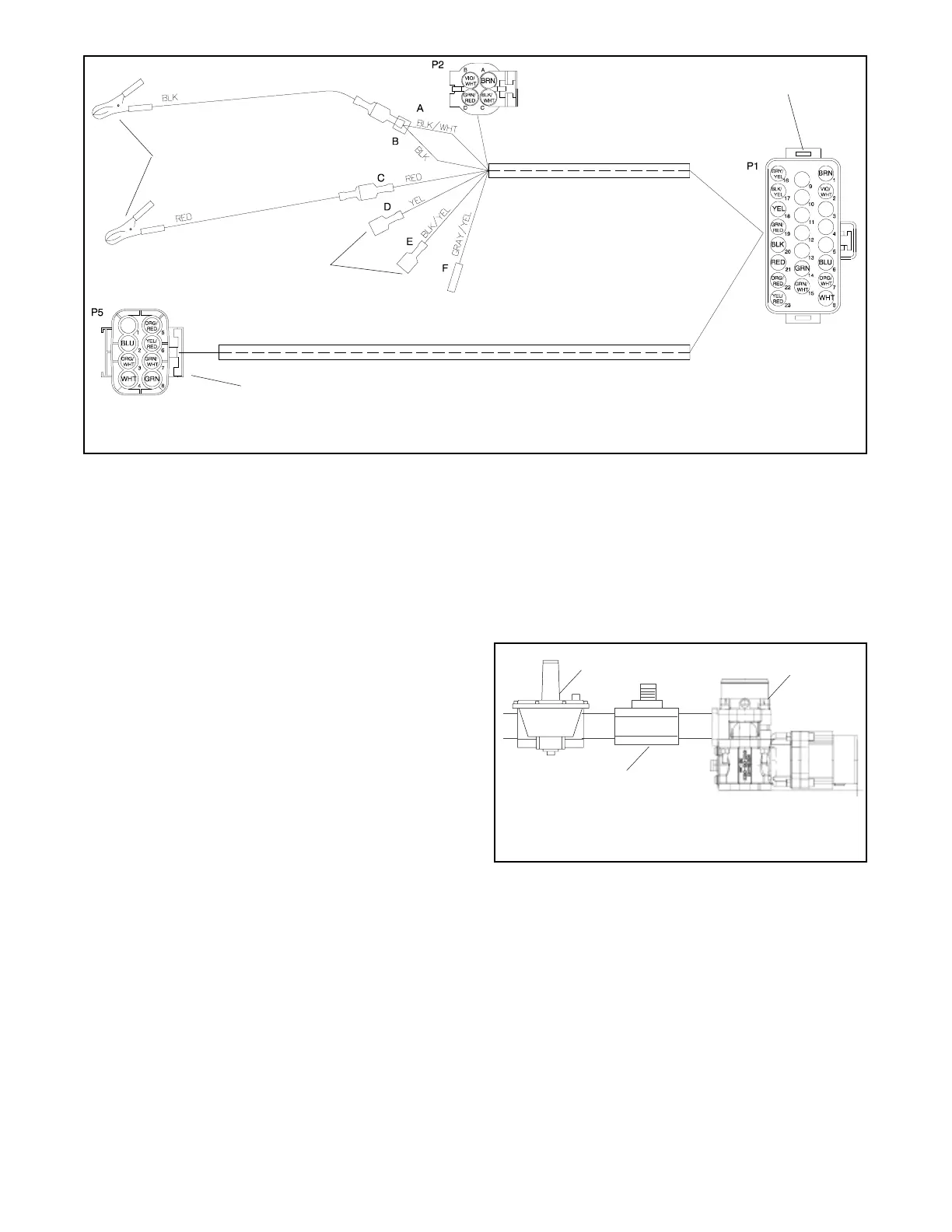

a. 30--60 kW generator sets. Venturi style gas

mixer used with an integrated throttle body

governor on 4.3 L, 5.0 L, and 5.7 L GM engines.

Also similar to the IMPCO model 100 used on

the 30 kW with 3.0 L GM engine. See

Figure 9-48.

1. Zero pressure fuel regulator

2. Fuel mixture adjustment

3. Venturi style gas mixer

3267

1

2

3

Figure 9-48 30--60 kW with Venturi Style Fuel Mixer

D Placethecontrollermasterswitchinthe

RUN position to start generator set.

D Allow generator set to run until the generator

set reaches normal operating temperature.

D Apply 90%--100% of full rated load.

Loading...

Loading...