185Section 9 Gas Fuel SystemsTP-6356 4/12

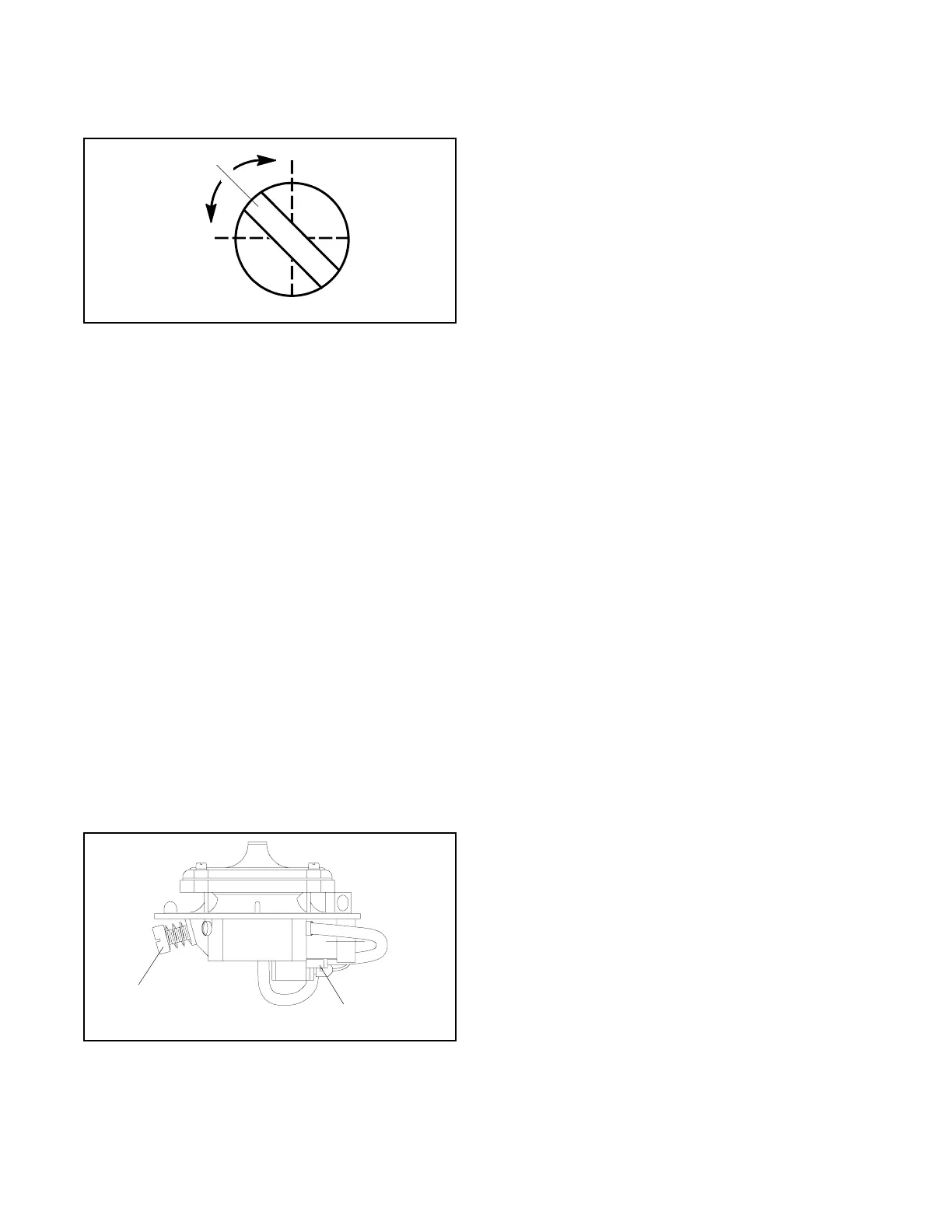

D Adjust the fuel mixture adjustment (see

Figure 9-48 and Figure 9-49) to obtain a full

load oxygen sensor voltage reading in the

range specified in Figure 9-44.

1

2

3

TP-5750-3

1. Fuel adjusting screw

2. Lean

3. Rich

Figure 9-49 Fuel Mixture Adjustment, Typical

D Disconnect the load.

D Adjust the zero pressure regulator (see

Figure 9-48 and Figure 9-49) to obtain a no

load oxygen sensor voltage reading in the

range specified in Figure 9-44.

D Repeat the steps from applying load through

adjusting the zero pressure regulator until

the oxygen sensor voltage reading is in the

specified range for both no-load and full-load

conditions.

D Remove load and allow generator set to run

unloaded to cool for at least 5--10 minutes.

D Place the controller master switch in the OFF

position to stop generator set.

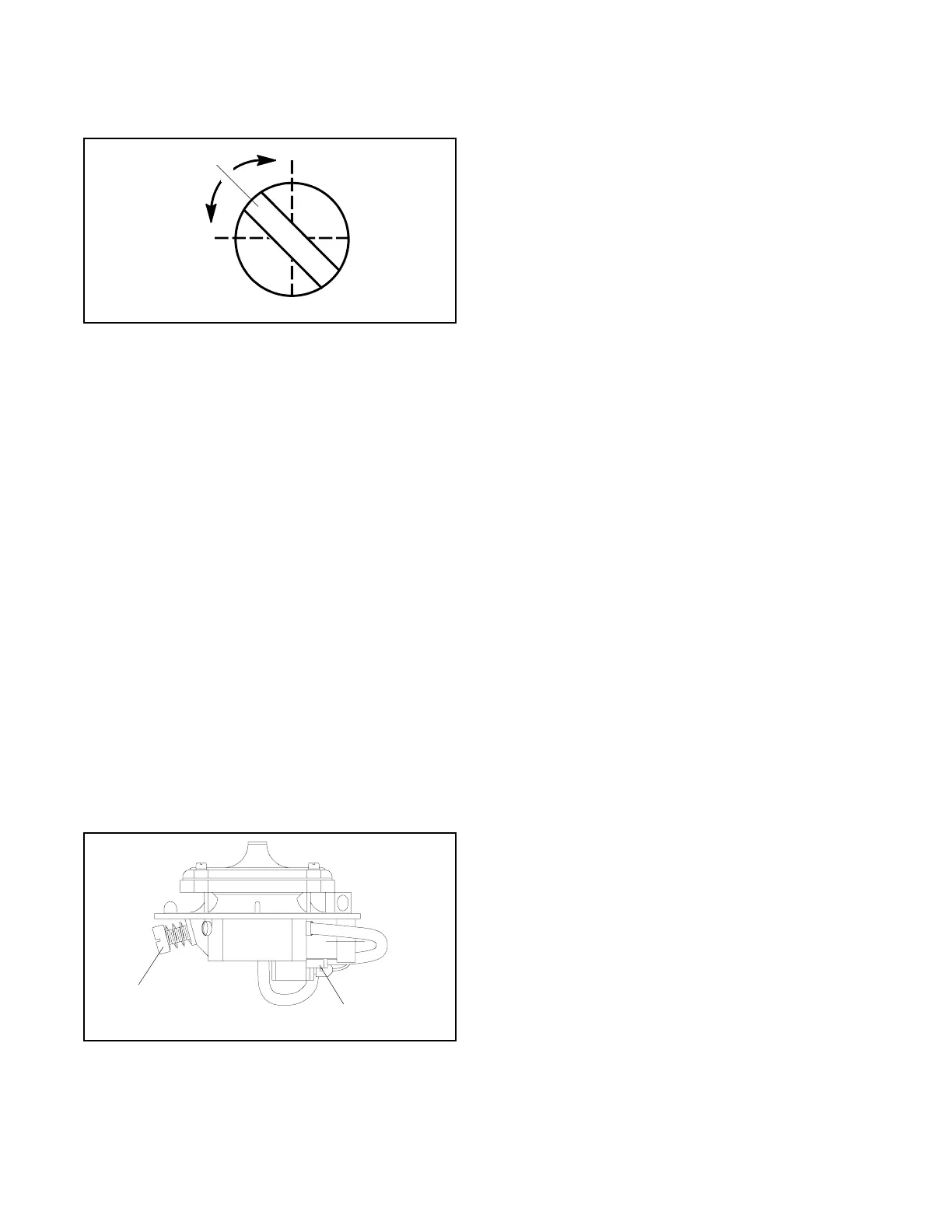

b. 30--80 kW generator sets. Nolff NCA-225M

and NCA-125M style gas mixers used on early

versions of 30--60 kW 4.3 L and 5.7 L GM

engines, 30--60 kW LP liquid withdrawal

systems, and 80 kW 8.1 L GM engines. See

Figure 9-50.

1. Fuel mixture adjustment 2. Power adjustment

324742

1

2

Figure 9-50 30--80 kW with Nolff NCA-225M and

NCA-125M Style Fuel Mixers

D Adjust the fuel regulator adjustment screw to

the approximate midpoint of its adjustment

range. See Figure 9-49.

D Placethecontrollermasterswitchinthe

RUN position to start generator set.

Note: If the generator set fails to start, turn

the fuel regulator adjustment screw

slightly in or out while the engine

cranks.

D Allow the generator set to run until the

generator set reaches normal operating

temperature.

D Apply 90%--100% of full rated load.

D Adjust the fuel mixture adjustment

(Figure 9-50) to obtain a full load oxygen

sensor voltage reading in the range specified

in Figure 9-44.

If the oxygen sensor voltage reading is

too low with the fuel mixture adjustment in

the richest position (turned in CW), turn the

fuel regulator adjustment screw CW to

richen the fuel mixture. Readjust the fuel

mixture adjustment as needed to obtain an

oxygen sensor voltage reading within

specifications.

If the oxygen sensor voltage reading is

too high with the fuel mixture adjustment in

the leanest position (turned out CCW), turn

the fuel regulator adjustment screw CCW to

lean the fuel mixture. Readjust the fuel

mixture adjustment as needed to obtain an

oxygen sensor voltage reading within

specifications.

D Disconnect the load.

D Adjust the fuel mixture adjustment to obtain

a no load oxygen sensor voltage reading

within the specifications shown in

Figure 9-44.

If the oxygen sensor specification cannot be

met at no load, turn the idle mixture screw in

to the richest possible setting.

D Repeat steps from applying full rated load

through adjusting the fuel mixture to obtain a

no load oxygen sensor voltage reading with

specifications to verify the settings.

D Place the controller master switch in the OFF

position to stop generator set.

Loading...

Loading...