OM4056 7/11 Lubrication and Service - Section 40

Page 40-13

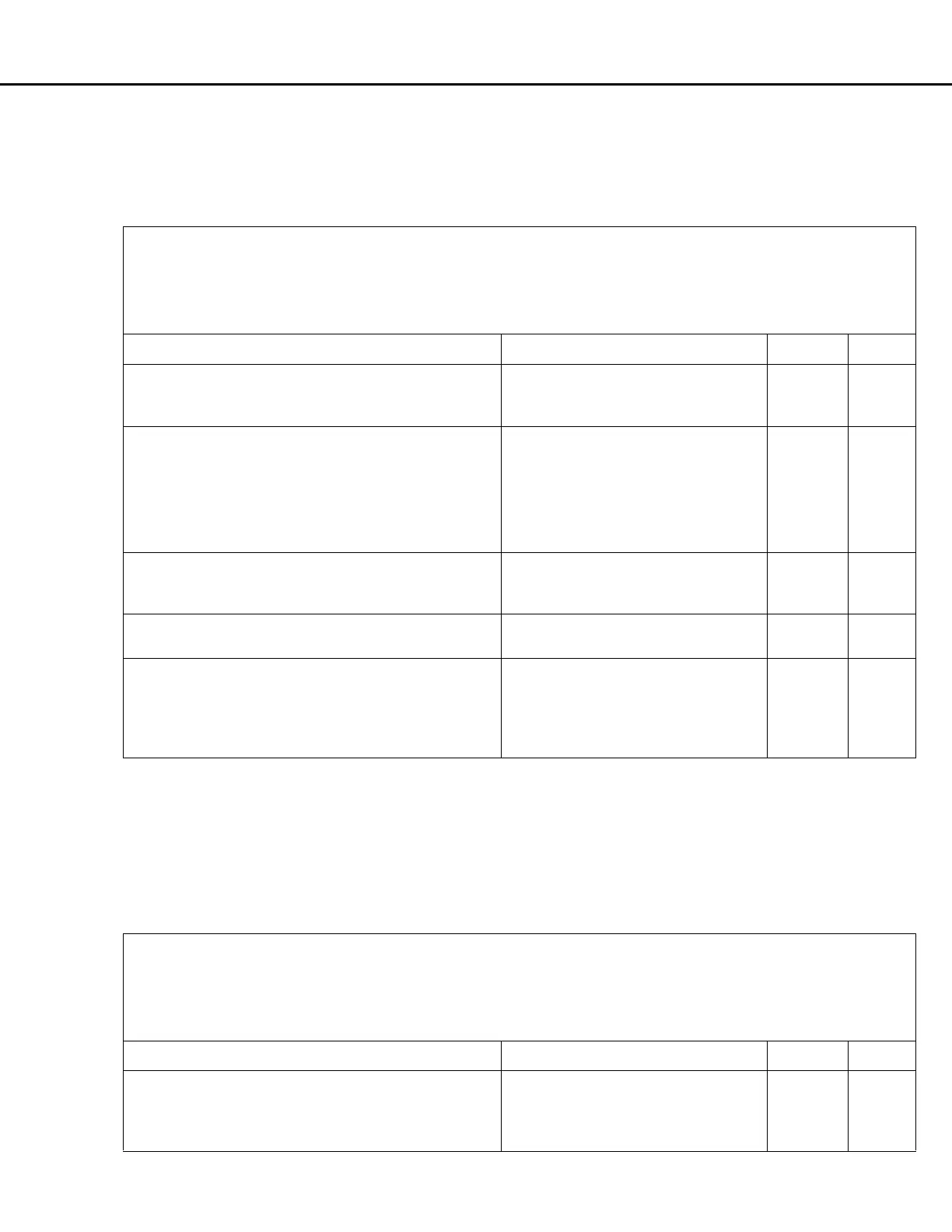

1000 HOUR LUBRICATION AND MAINTENANCE CHECKS

All 10 Hour (Daily) Inspections, 250 Hour Lubrication and Maintenance Checks, and 500 Hour Lubrication and

Maintenance Checks should also be performed at this time.

NOTE: “Lube Key” references are to the Lubrication Chart on page 40-5.

5000 HOUR MAINTENANCE CHECKS

All 10 Hour (Daily) Inspections, 250 Hour Lubrication and Maintenance Checks, 500 Hour Lubrication and

Maintenance Checks, and 1000 Hour Lubrication and Maintenance Checks should also be performed at this time.

NOTE: “Lube Key” references are to the Lubrication Chart on page 40-5.

Truck Serial Number______________________ Site Unit Number_______________ Date_______________

Hourmeter_____________ Name of Service Technician___________________________________

TASK COMMENTS CHECKED INITIALS

1. HYDRAULIC TANK - Drain the hydraulic tank and

clean the inlet strainers. Refer to Section L3 in the

shop manual. Refill the hydraulic tank. (Lube Key “B”)

2. RADIATOR - Clean the cooling system with a good

quality cleaning compound. Flush with water.

Fill the radiator with the proper coolant mixture

according to Coolant Specifications on page 40-2.

Refer to the engine service manual for additional

coolant recommendations.

3. FUEL TANK - Remove the fuel tank breather and

clean it in solvent. Dry the breather with pressurized

air and install it on the tank.

4. OPERATOR'S SEAT - Apply grease to the slide rails.

(Lube Key “D”)

5. AUTOMATIC BRAKE APPLICATION - Make sure that

the brakes are automatically applied when the brake

pressure decreases below the specified limit. Refer to

Section J, Brake Circuit Check-Out Procedure, in the

shop manual.

Truck Serial Number______________________ Site Unit Number_______________ Date_______________

Hourmeter_____________ Name of Service Technician___________________________________

TASK COMMENTS CHECKED INITIALS

1. AIR CLEANERS - Clean the Donaclone tubes in the

precleaner section of the air filter. Use low pressure

cold water or low pressure air to clean the tubes.

Refer to Section C5 in the shop manual.