Automatic Lubrication System - Section 42 7/11 OM4213

Page 42-12

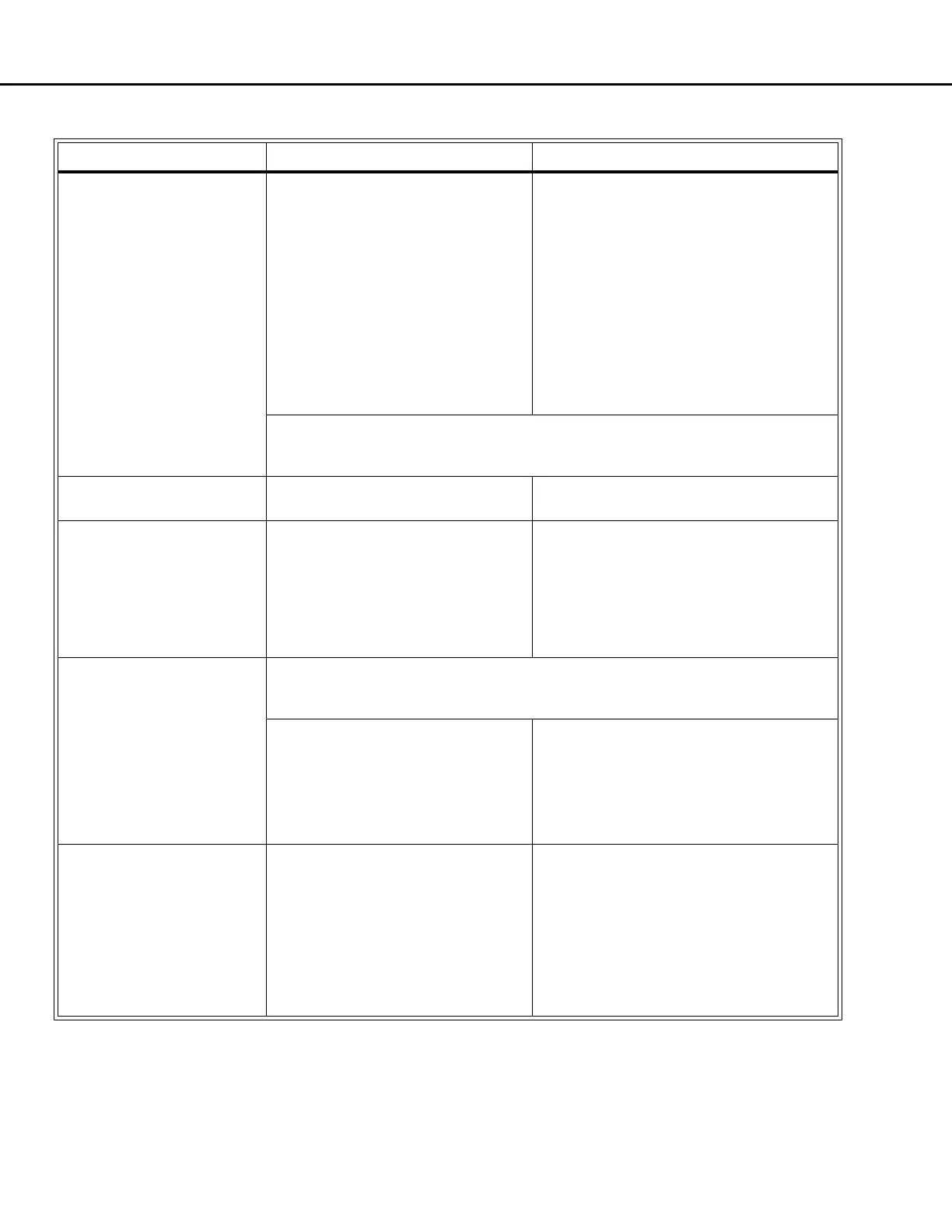

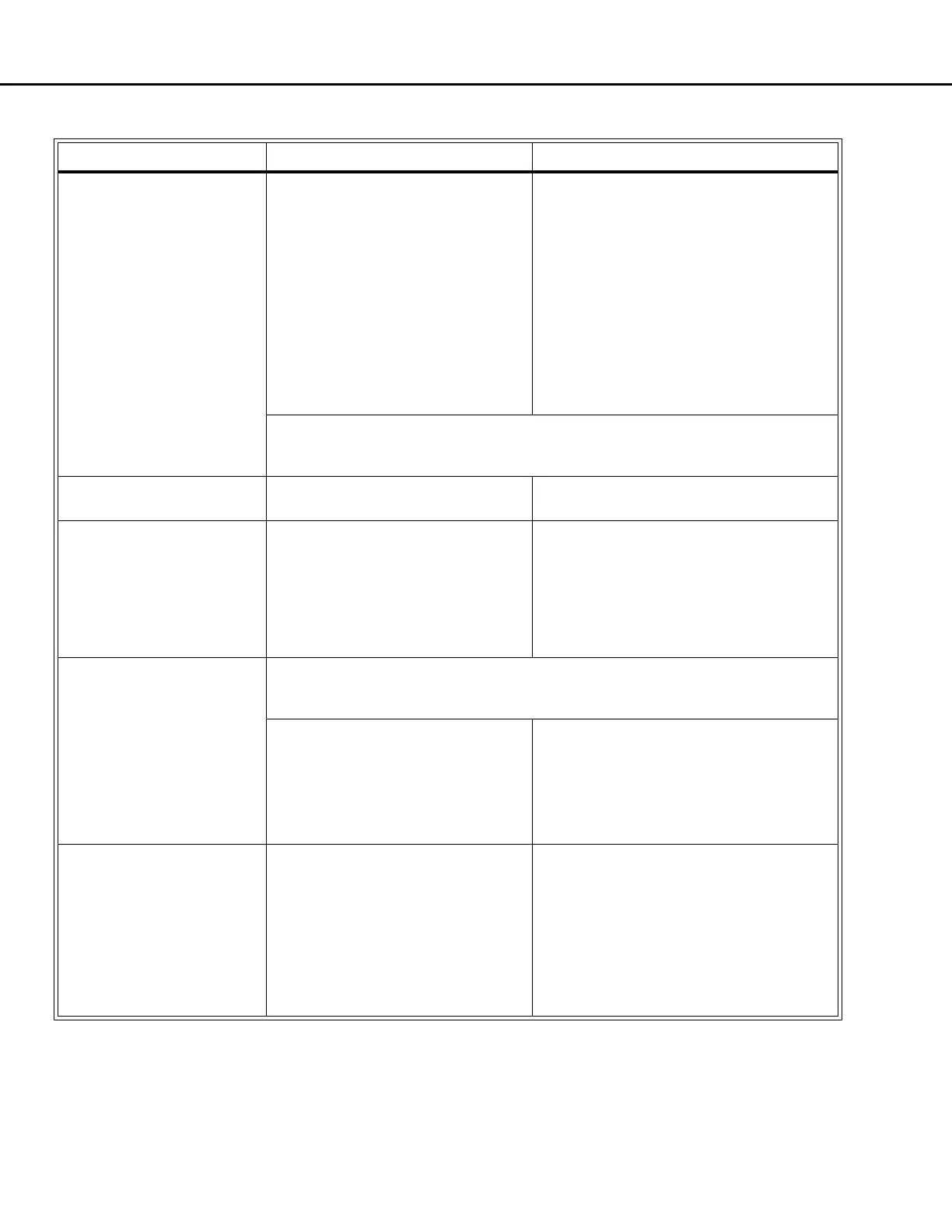

SYSTEM TROUBLESHOOTING CHART

NOTE: If the following procedures do not correct the problem, contact a factory authorized service center.

TROUBLE POSSIBLE CAUSES SUGGESTED CORRECTIVE ACTION

Pump Does Not Operate

Lube system not grounded.

Electrical power loss.

Timer malfunction.

Solenoid valve malfunctioning.

Relay malfunctioning.

Motor or pump malfunction.

Correct grounding connections to pump

assembly and truck chassis.

Locate cause of power loss and repair.

24 VDC power required. Ensure key

switch is ON.

Replace timer assembly.

Replace the solenoid valve assembly.

Replace relay.

Repair or replace motor and/or pump

assembly. (Refer to shop manual for

rebuild instructions.)

NOTE: On initial startup of the lube system, the timing capacitor will not contain a

charge, therefore the first timing cycle will be about double in length compared to

the normal interval. Subsequent timer cycles should be as specified.

Pump Will Not Prime

Low lubricant supply. Dirt in reservoir, pump inlet clogged, filter

clogged.

Pump Will Not Build

Pressure

Air trapped in lubricant supply line.

Lubricant supply line leaking.

Vent valve leaking.

Pump is worn or scored.

Prime system to remove trapped air.

Check lines and connections to repair

leakage.

Clean or replace vent valve.

Repair or replace pump assembly. (Refer

to shop manual for rebuild instructions.)

Injector Indicator Stem

Does Not Operate

NOTE: Normally, during operation, the injector indicator stem will move into the

body of the injector when pressure builds properly. When the system vents

(pressure release) the indicator stem will again move out into the adjusting yoke.

Malfunctioning injector - usually

indicated by the pump building

pressure and then venting.

All injectors inoperative - pump

build up not sufficient to cycle

injectors.

Replace individual injector assembly.

Service and/or replace pump assembly.

(Refer to shop manual for rebuild

instructions.)

Pressure Gauge Does Not

Register Pressure

(pressure gauge not

included with pump)

No system pressure to the pump

motor.

No 24 VDC signal at pump

solenoid.

Pressure reducing valve set too low.

24V Relay (RB7K8 or RB7K5) may

be defective.

Check hydraulic hose from steering

system.

Determine problem in 24 VDC electric

system.

Refer to “Pressure Control Valve

Adjustment”.

Replace relay.

Loading...

Loading...