Checking and adjusting track

shoe tension 1

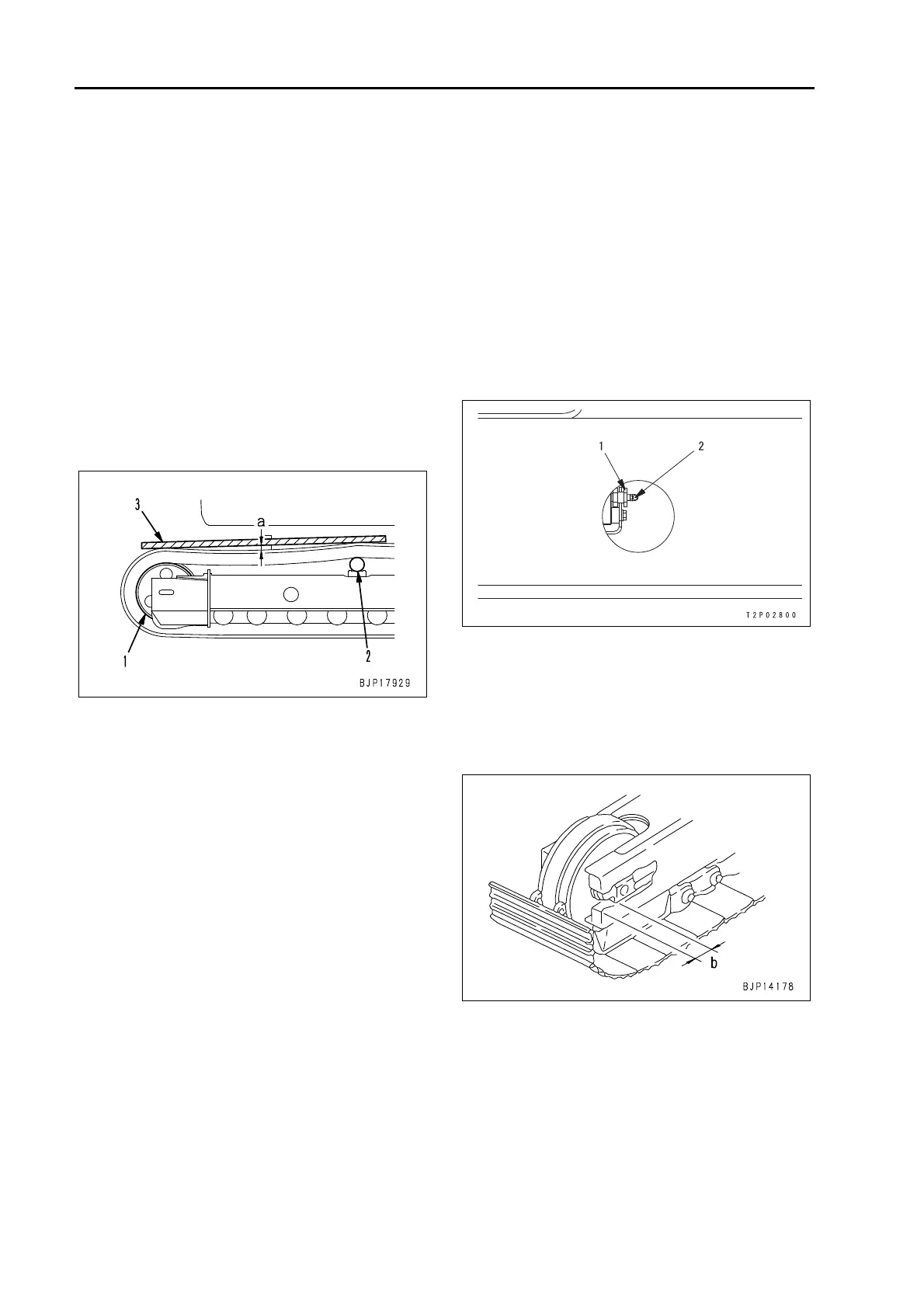

Checking

1. Run the engine at low idle and drive the

machine forward by the length of track on

ground, and then stop slowly.

2. Place square bar [3] longer than the distance

between idler (1) and carrier roller (2) on the

track shoe.

a As the steel bar, use an angle steel, etc.

which will be deflected less.

3. Test maximum clearance (a) between steel bar

[3] and track shoe.

q Standard maximum clearance (a):

10 30 mm

Adjusting

a If the track shoe tension is abnormal, adjust it

according to the following procedure.

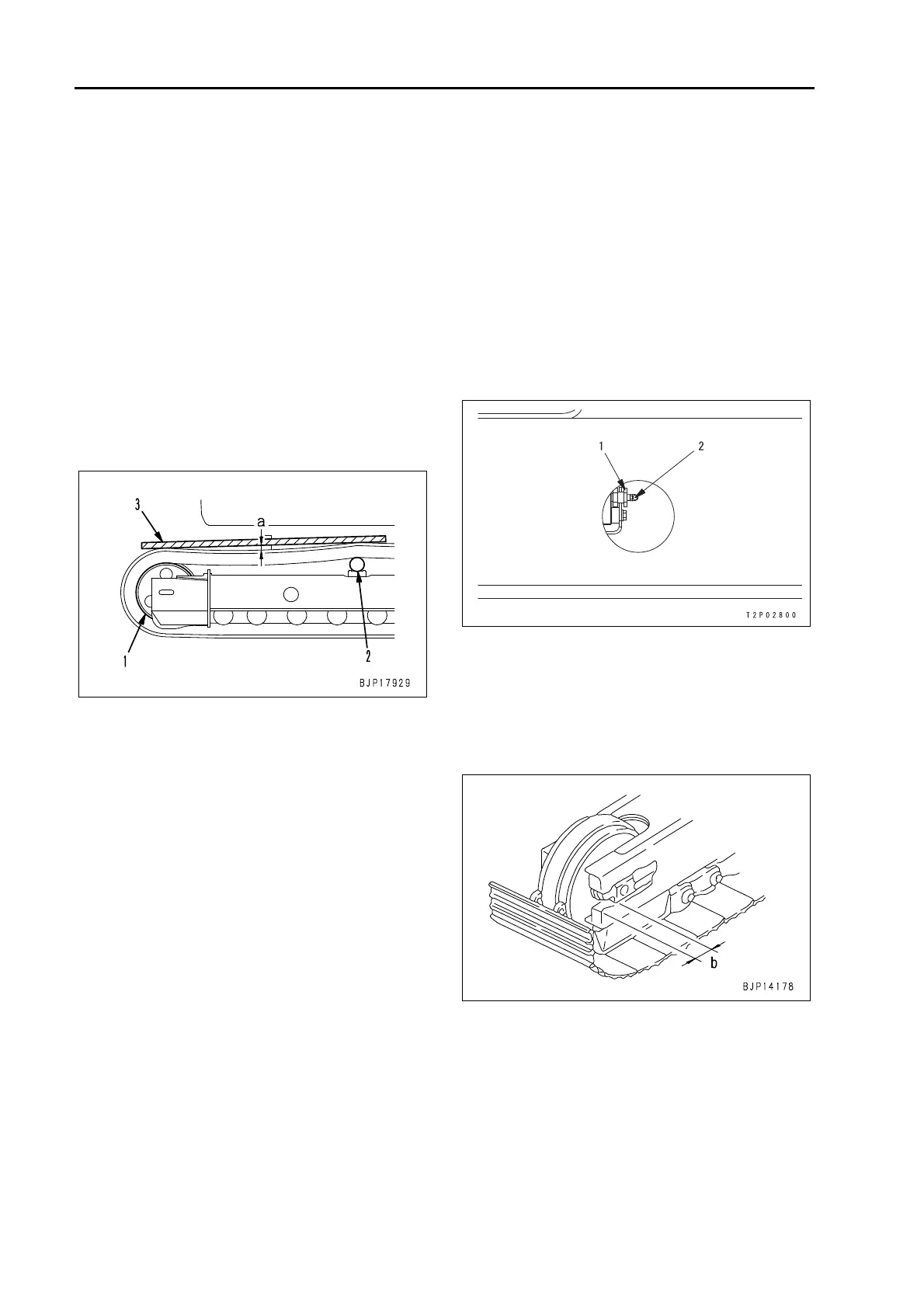

1. Increasing tension

1) Add grease through grease fitting (2) with

a grease gun.

2) To check that the tension is normal, run

the engine at low idle and move the

machine forward by the length of track on

ground, then stop slowly.

3) After adjusting, check the track shoe ten-

sion again according to the above proce-

dure.

a You may add grease until dimension (b)

between the idler guide and track frame

end becomes 0 mm. If the tension is still

low, the pins and bushings are worn

much. In this case, reverse or replace the

pins and bushings.

Loading...

Loading...