Testing oil leakage 1

a Testing tools for oil leakage

a Test the oil leakage under the following condi-

tion.

q Hydraulic oil temperature: Within operating

range

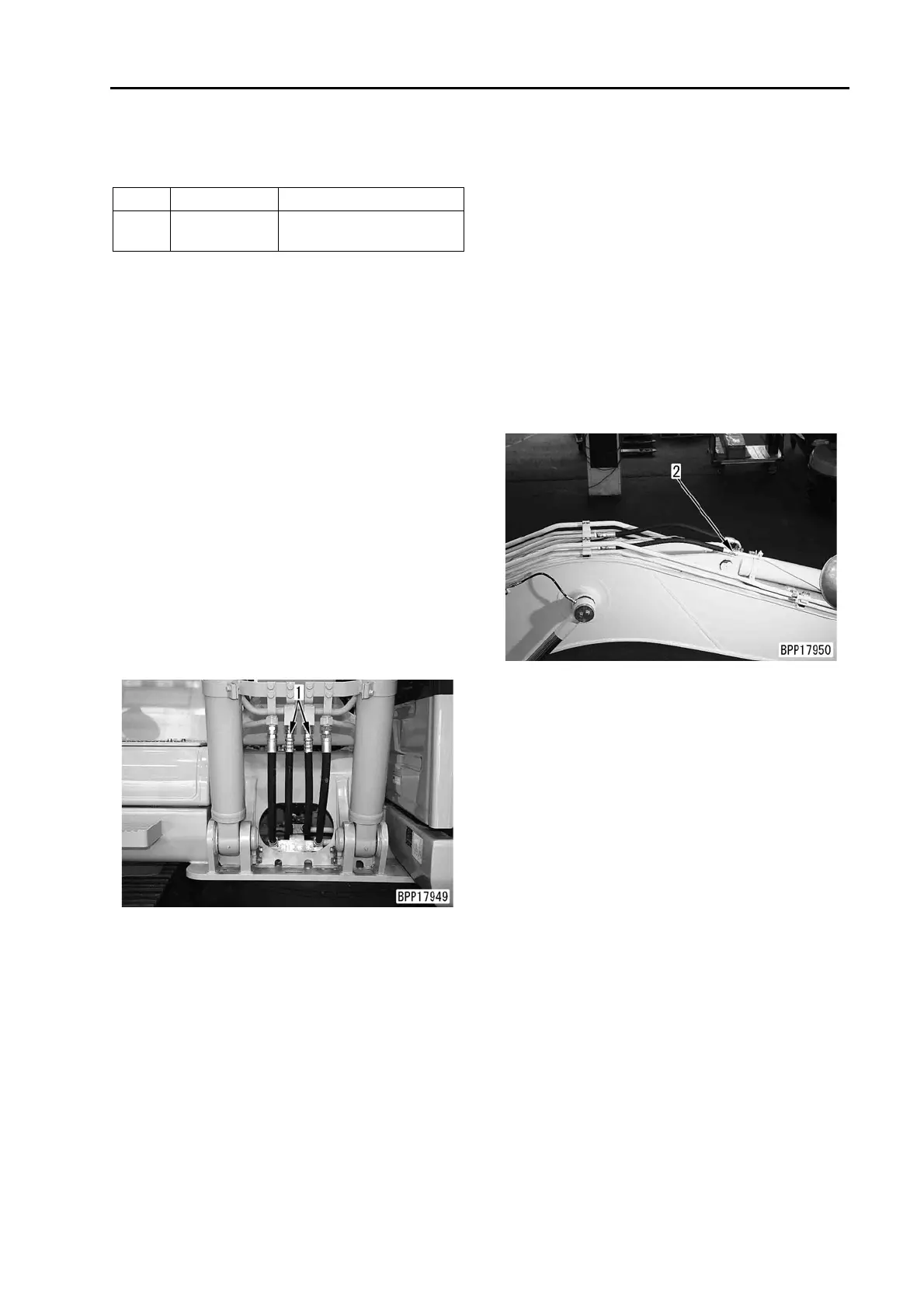

1. Testing oil leakage from boom cylinder

1) Move the boom cylinder to the RAISE

stroke end and stop the engine.

k Release the residual pressure from

the piping on the boom cylinder

head side. For details, see "Releas-

ing residual pressure from hydrau-

lic circuit" (Operate the lever in the

boom RAISE direction only, how-

ever).

2) Disconnect hose (1) on the cylinder head

side and block it with a plug.

k Take care not to disconnect the

hose on the cylinder bottom side.

a Use the following part to block the

hose side.

07379-00640 (Flange #06)

3) Run the engine at high idle and relieve the

boom circuit by raising the boom.

k Take care not to "lower the boom".

4) Start testing the oil leakage 30 seconds

after relieving is started and test for 1 min-

ute.

5) After finishing test, return the removed

parts.

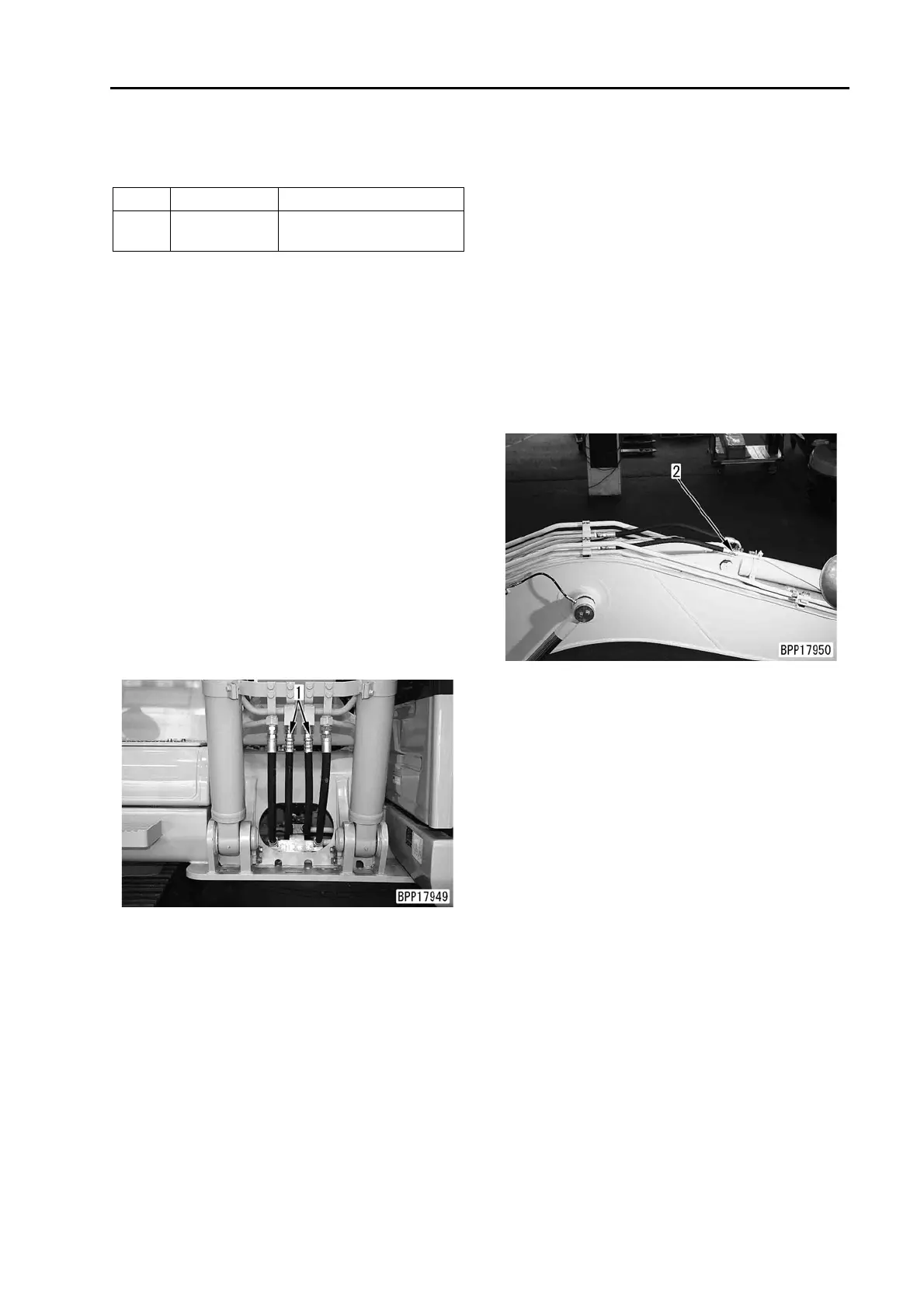

2. Testing oil leakage from arm cylinder

1) Move the arm cylinder to the IN stroke end

and stop the engine.

k Release the residual pressure from

the piping on the arm cylinder

head side. For details, see Releas-

ing residual pressure from hydrau-

lic circuit (Operate the lever in the

arm IN direction only, however).

2) Disconnect hose (2) on the cylinder head

side and block it with a plug.

k Take care not to disconnect the

hose on the cylinder bottom side.

a Use the following part to block the

hose side.

07376-70522 (Plug #05)

3) Run the engine at high idle and relieve the

arm circuit by moving the arm IN.

k Take care not to "move the arm

OUT".

4) Start testing the oil leakage 30 seconds

after relieving is started and test for 1 min-

ute.

5) After finishing test, return the removed

parts.

Symbol Part No. Part name

Q

Commercially

available

Measuring cylinder

Loading...

Loading...