SEN04130-01 50 Disassembly and assembly

16 PC130-8

Disassembly and assembly of

control valve assembly 1

Assembly

a In this section, only precautions for assembling

the control valve assembly are explained.

a The

port Nos. in the drawings refer to the port

Nos. of the hoses that are specified to be dis-

connected in "Removal and installation of con-

trol valve assembly".

a The

number in ( ) attached to each tightening

torque shown in the drawings indicates the

number of bolts, plugs, etc.

q Coat the sliding surfaces of the parts with

engine oil before assembling.

2 Mating face:

Gasket sealant (SEALEND 242 or equivalent)

q The tightening torque and precautions for each

part are as follows. (Random order)

q Installation of cover (1):

Tighten nuts (17) in the order of [1] – [4] in 3

tim

es.

3 1st time: 58.8 – 68.6 Nm {6 – 7 kgm}

2nd time:7

8.5 – 88.3 Nm {8 – 9 kgm}

3rd time: 9

8.1 – 113 Nm {10 – 11.5 kgm}

a Pro

jection of stud end from nut end: 0.5 – 3

mm

q Assembly of block (10)

Tighten bolts (18) in the order of [1] – [4] in 3

tim

es.

3 1st time: 19.6 – 29.4 Nm {2 – 3 kgm}

2nd time:3

9.2 – 49.0 Nm {4 – 5 kgm}

3rd time: 5

8.8 – 73.5 Nm {6 – 7.5 kgm}

[*1]

q When tightening or loosening a plug shown in

sections G-G, M-M, N-N and AA-AA, be sure to

keep the spool in the valve body.

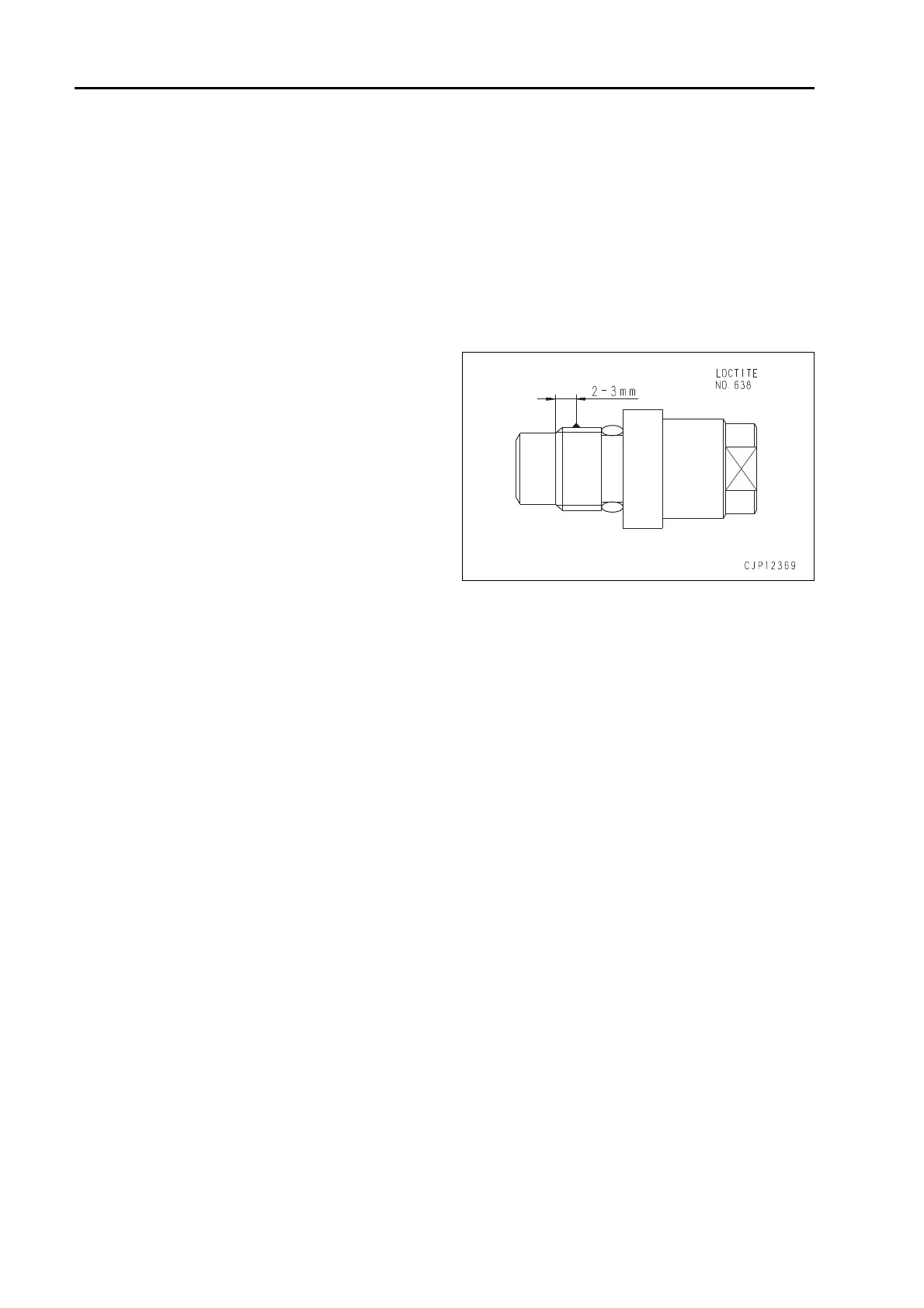

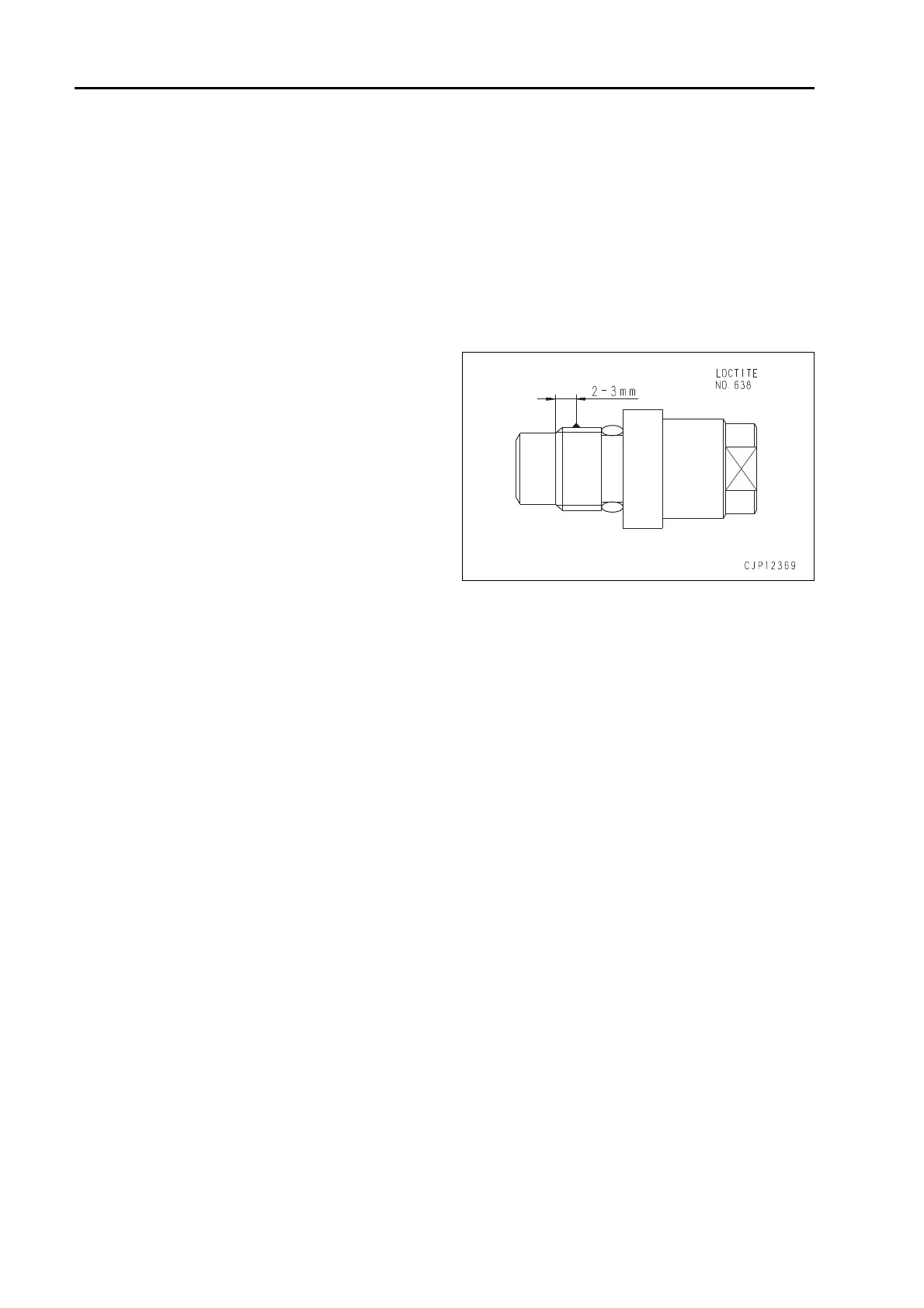

q When tightening each plug, apply a drop of

(approx. 0.02 g) LOCTITE (No. 638) to it.

a Tho

roughly degrease each plug and

female threaded part with denatured alco-

hol etc. and then dry them before tighten-

ing them. Do not apply pressure to them

for 2 hours after tightening them.

(Part to drop LOCTITE)

Loading...

Loading...