Testing and adjusting oil pressure

in pump LS control circuit 1

a Testing and adjusting tools for oil pressure in

pump LS control circuit

k Stop the machine on a level ground and

lower the work equipment to the ground.

Then, release the residual pressure from

the hydraulic circuit. For details, see

"Releasing residual pressure from hydrau-

lic circuit".

Testing

a Before testing the oil pressure in the LS control

circuit, check that the oil pressure in the work

equipment, swing, and travel circuits and the

basic pressure of the control circuit are normal.

a Test the oil pressure in the pump LS control cir-

cuit under the following condition.

q Hydraulic oil temperature: Within operating

range

1. Testing LS valve output pressure (servo

piston inlet pressure)

a Test the LS valve output pressure (servo

piston inlet pressure) and pump discharge

pressure simultaneously and compare

them.

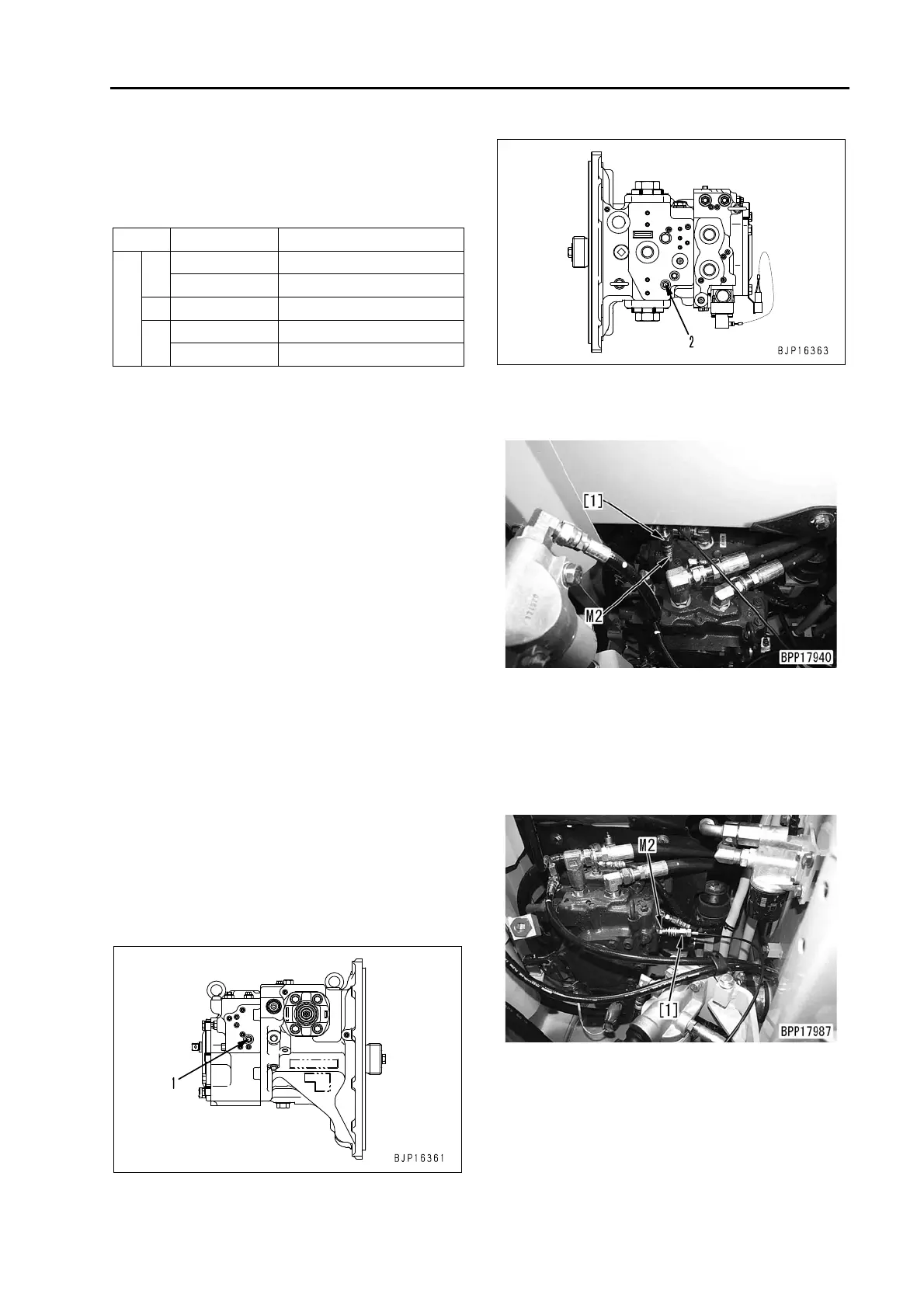

1) Open the side cover of the pump room

and remove oil pressure pickup plugs (1)

and (2).

q (1): Pump discharge pressure pickup

plug

q (2): LS valve output pressure pickup

plug

2) Install nipple M3 and connect it to oil pres-

sure gauge [1] of hydraulic tester M1.

a Install nipple M3 to the inspection part

of plug (2) and connect it to oil pres-

sure gauge [1] by hose [2] of hydrau-

lic tester M1.

a Use the oil pressure gauges of 58.8

MPa {600 kg/cm

2

}.

3) Start the engine and push up the track

shoe on the side to be tested with the

work equipment and prepare for running

the track shoe idle.

k Since the raised track shoe will be

run idle during test, secure a suffi-

cient working area.

Symbol Part No. Part name

M

1

799-101-5002 Hydraulic tester

790-261-1204 Digital hydraulic tester

2 799-401-2701 Differential pressure gauge

3

799-101-5220 Nipple (10 × 1.25 mm)

07002-11023 O-ring