2.

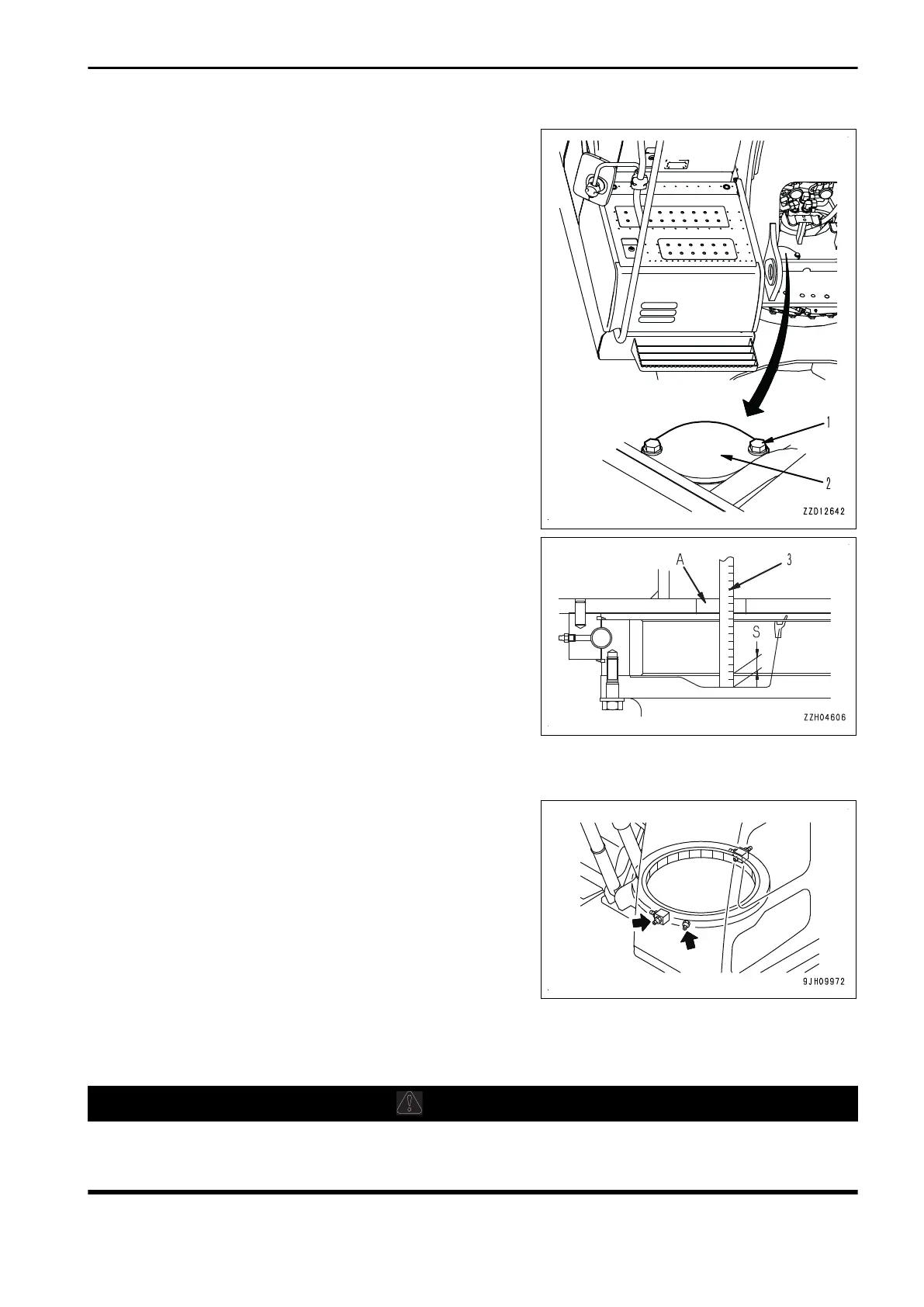

Remove bolts (1) (2 pieces) on the top of the revolving

frame, and remove cover (2).

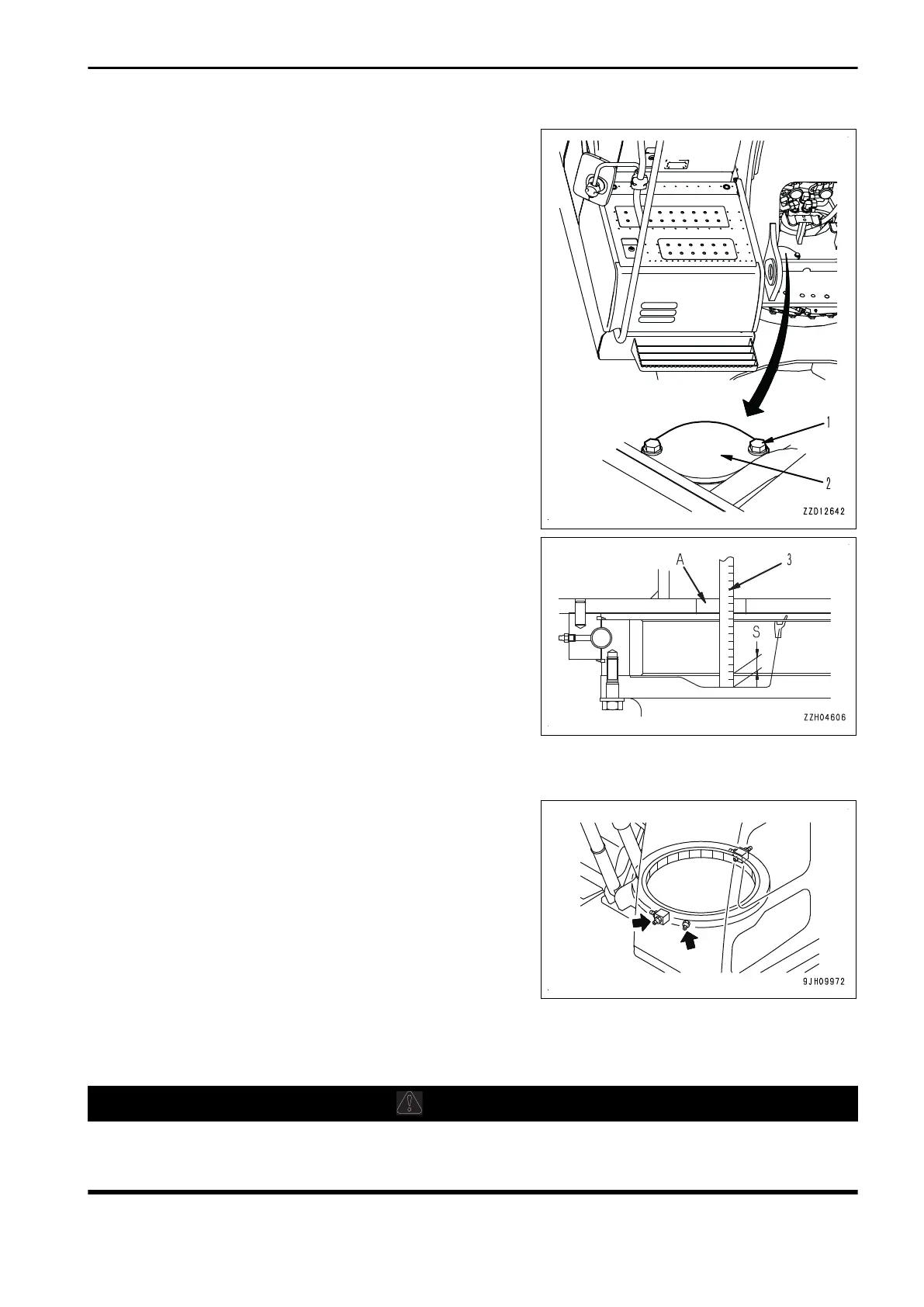

3.

Insert ruler (3) into the grease through inspection and ad-

justment hole (A). Check that the height of grease (S) in

the area where the pinion passes is at least 9 mm.

Add grease if the grease amount (S) is less than 9 mm.

4.

Check that the grease is not milky white.

Total amount of grease: 14.6 ℓ.

If the grease is milky white, it needs to be replaced. Ask

your Komatsu distributor to replace it.

5.

Install cover (2) with bolt (1).

METHOD FOR LUBRICATING SWING CIRCLE

Lower the work equipment to the ground.

1.

By using a grease pump, pump in grease through the

grease fittings shown by arrows. (2 places)

2.

After greasing, wipe off any old grease that is pushed out.

METHOD FOR CHECKING AND CLEANING RADIATOR FINS, OIL COOLER FINS,

AFTERCOOLER FINS, FUEL COOLER FINS, AND AIR CONDITIONER CONDENS-

ER FINS

WARNING

If compressed air, high-pressure water, or steam hits your body directly or dirt is scattered by the com-

pressed air, high-pressure water, or steam, there is a danger of personal injury. Always wear protective

equipment such as protective eyeglasses and dust mask.

MAINTENANCE MAINTENANCE PROCEDURE

4-51

Loading...

Loading...