Omega

14

7.5 Instructions for Replacing Subassemblies

7.5.1 Replacing the Shaft Seal

Proceed as described in section 8.1 and 8.2.

7.5.2 Replacing Casing Wear Rings and / or Impeller

Wear Rings

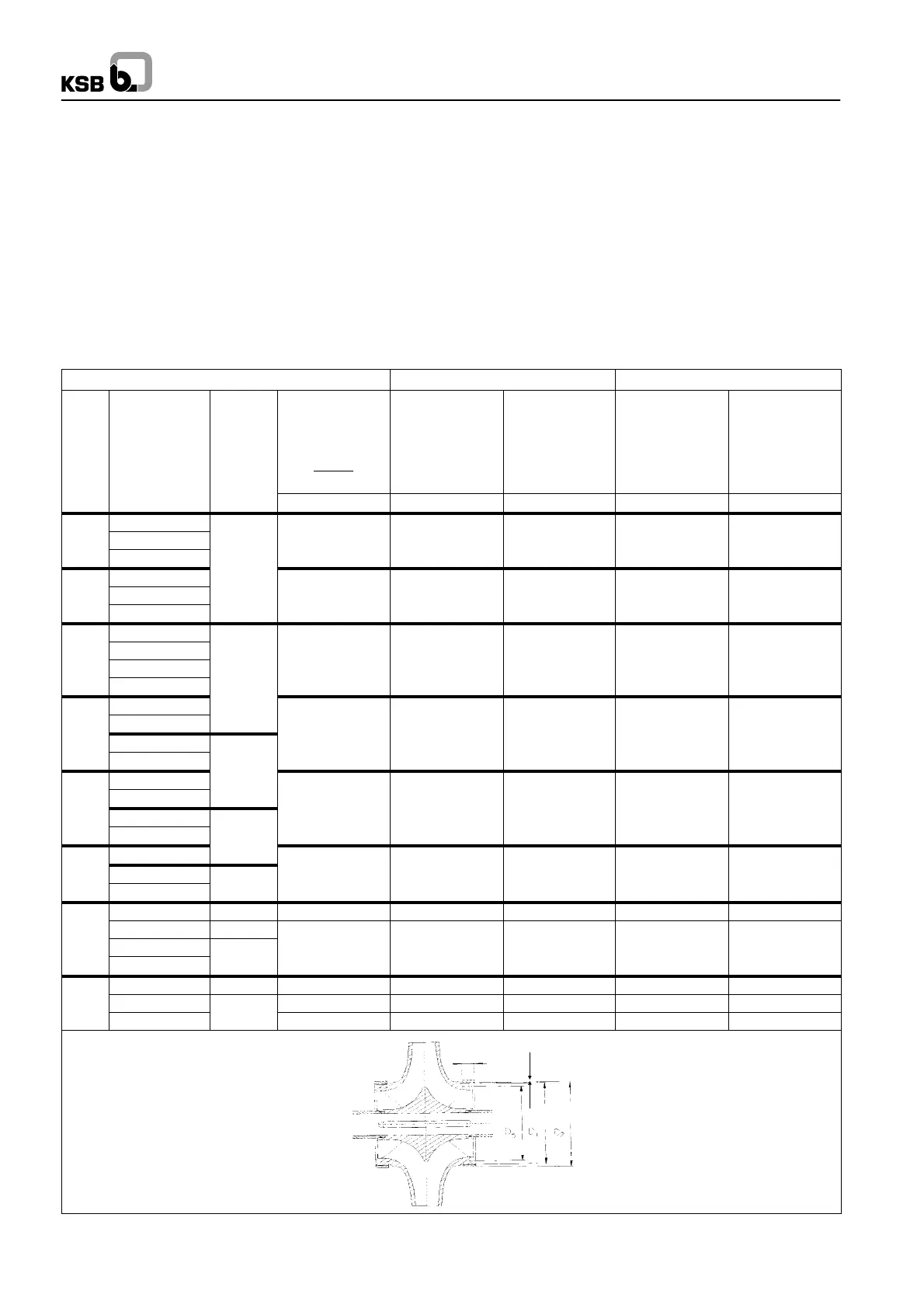

The impeller clearance

1)

clearance between impeller 234 and

casing wear ring 502 is given in the table below.

For impeller removal proceed as described in section 7.3,

”Dismantling”.

Impeller clearances and trim dimensions for impeller wear rings

After dismantling as described in section 7.3.2, the casing wear

rings (502) can be removed. When fitting the rings, ensure that

their bezels are on the outside (towards the bearing). The pins

(561.01) must be positioned as shown in the diagram below.

If the impeller has not been fitted with a wear ring at the factory,

and changing the casing wear ring alone does not achieve an-

ything close to the required impeller clearance (the impeller

neck is badly worn by clearance flows), the impeller neck must

be turned off on a lathe (contact KSB before doing so) and an

impeller wear ring fitted in addition (available as spare part).

Alternatively, a new impeller can be supplied at short notice.

Clearance (as--new) Dimensions of impeller wear ring

No. Pump

size

Shaft

unit

Nominal clea-

rance

(max. perm.)

D

2

-D

1

Min.

clearance

Smin

Max.

clearance

Smax

DW 2 D5 b

[mm] [mm] [mm] [mm] [mm]

1 80-210 0,3 0,15 0,2 134 r6 18

2 80-270 0,3 0,15 0,2 134 r6 18

3 80-370

0,3 0,15 0,2 134 r6 18

4 100-250

40

0,35 0,17 0,2 163 r6 22

5 100-310 0,35 0,17 0,2 163 r6 22

6 100-375 0,35 0,17 0,2 163 r6 22

7 125-230 0,35 0,18 0,23 178 r6 22

8 125-290 0,35 0,18 0,23 178 r6 22

9 125-365

0,35 0,18 0,23 178 r6 22

10 125-500

50

0,35 0,18 0,23 178 r6 22

11 150-290 0,45 0,22 0,26 210 r6 30

12 150-360 0,45 0,22 0,26 210 r6 30

13 150-460 0,45 0,22 0,26 210 r6 30

14 150-605

0,45 0,22 0,26 210 r6 30

15 200-320

60

0,5 0,24 0,28 243 r6 30

16 200-420 0,5 0,24 0,28 243 r6 30

17 200-520 0,5 0,24 0,28 243 r6 30

18 200-670

70

0,5 0,24 0,28 243 r6 30

19 250-370

0,5 0,24 0,28 276 r6 30

20 250-480

0,5 0,24 0,28 276 r6 30

21 250-600

80

0,5 0,24 0,28 276 r6 30

22 300-300 70 0,5 0,24 0,28 259 r6 30

23 300-435 80 0,6 0,29 0,35 313 r6 35

24 300-560

0,6 0,29 0,35 313 r6 35

25 300-700

90

0,6 0,29 0,35 313 r6 35

26 350-360 80 0,5 0,24 0,28 294 r6 35

27 350-430

0,6 0,32 0,37 333 r6 35

28 350-510

90

0,6 0,32 0,37 353 r6 35

b

S (min - max)

Loading...

Loading...