Omega

40

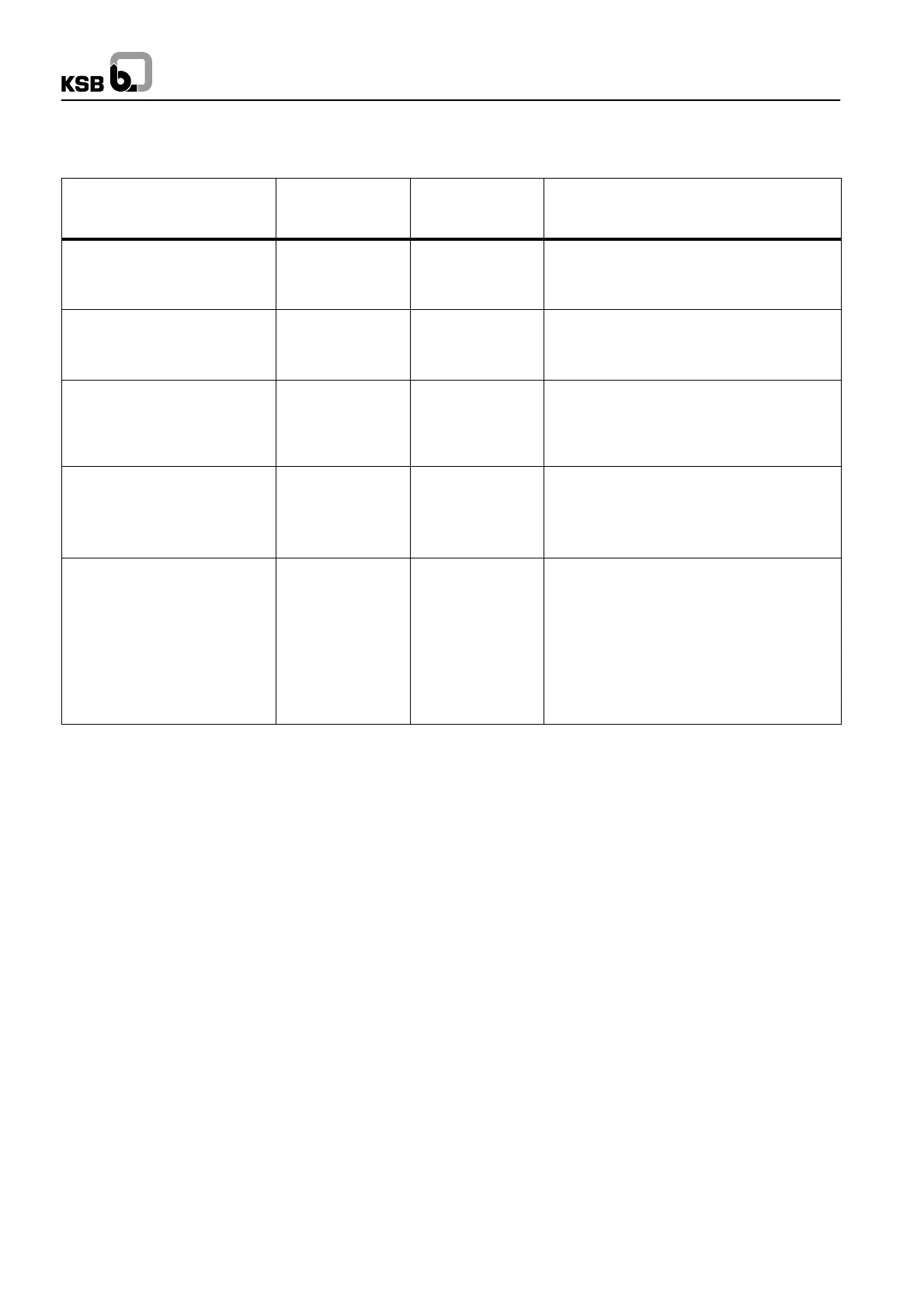

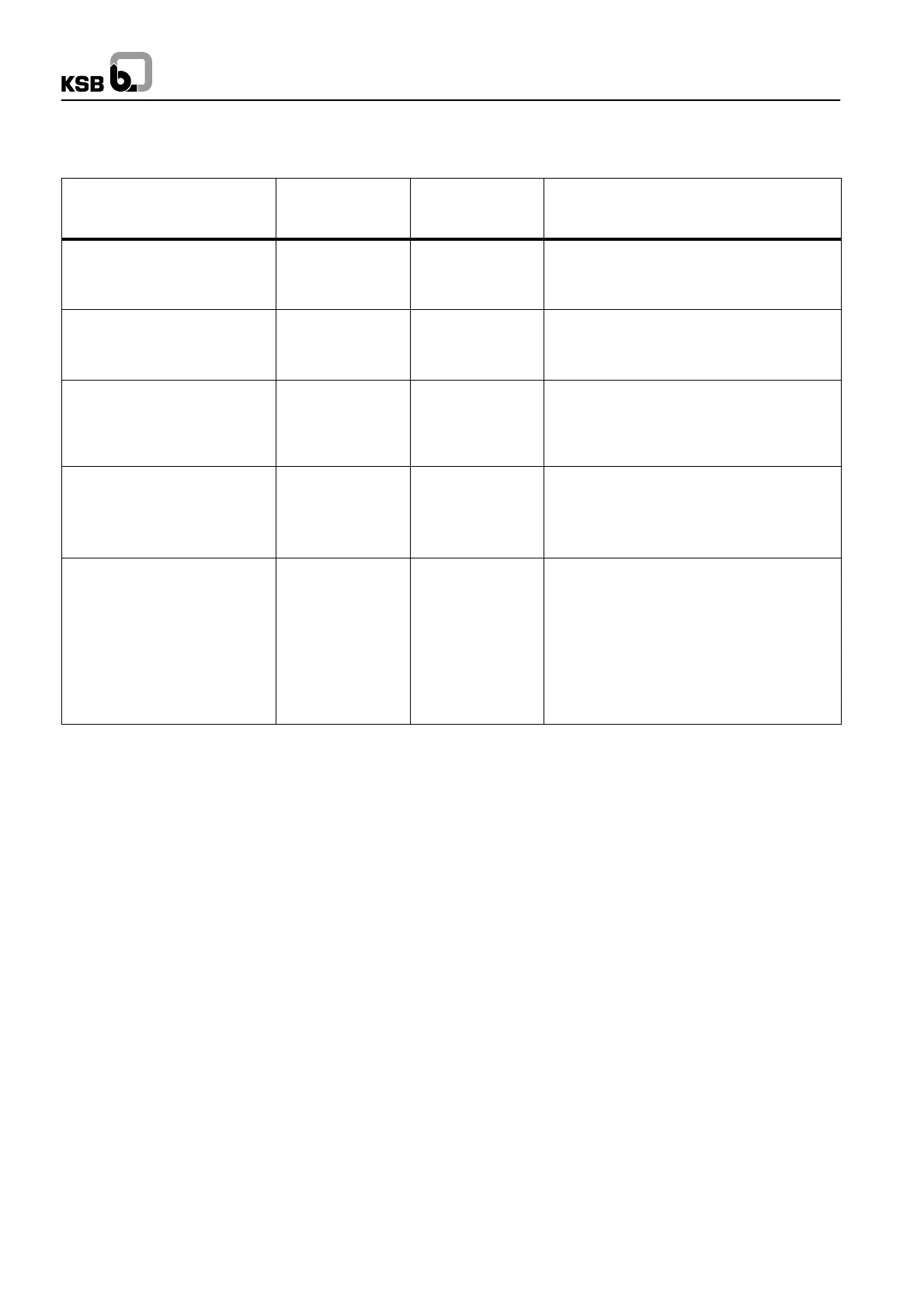

12 Routine Maintenance and Inspection Intervals

Interval Number of per -

sonnel required

Time

[h]

Maintenance job

Daily 1 1/10

Check leakage on mechanical seal or lea-

kage of packed gland

(see section 8.1 ”Gland packing”).

Weekly 1 1/4

Check pump operation (positive suction pres-

sure, total head, bearing temperature, noises

and vibrations)

Monthly

1

1

1/4

1/4

Check torsional play of coupling

(see section ”Coupling”),

If available, switch to stand--by pump or carry

out a test run (for 5 min.)

every 20.000

operating hours

2 3

Replace deep--groove ball bearings

(see section 7.3 ”Dismantling” and

7.4 ”Reassembly”).

every 4 years or if total

head of pump drops

2 6

General inspection and overhaul of pump in

accordance with the operating instructions.

Check and renew, if required:

-- wear parts such as: bearings, casing wear

ring (impeller wear ring, if any), shaft

protecting sleeve

-- impeller and shaft

-- Replace sealing elements

Loading...

Loading...