MAINTENANCE WORK ON CHASSIS AND ENGINE 44

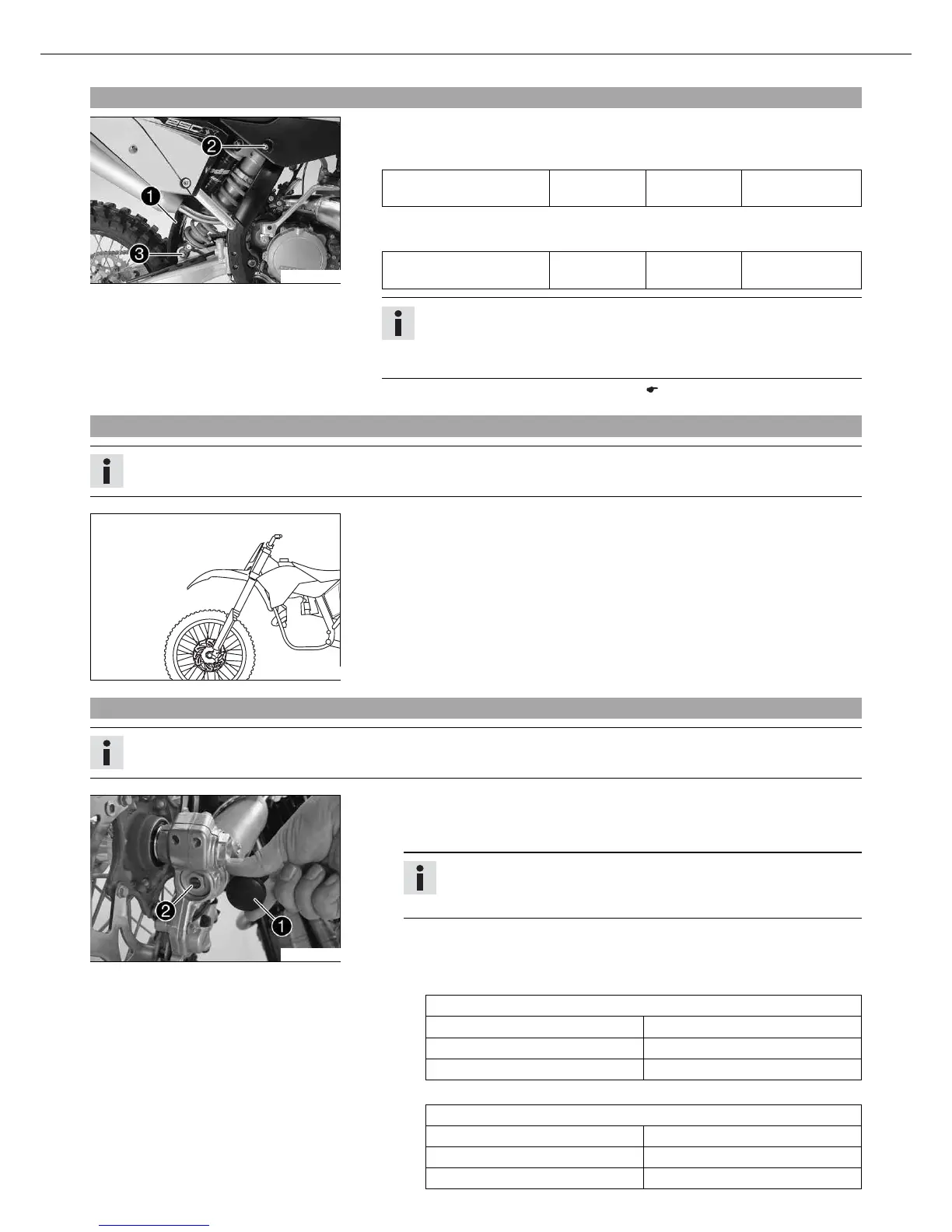

11.14Installing the shock absorber x

B00012-11

– Push splash protector to the side and position the shock absorber. Mount and

tighten screw .

Guideline

Screw, top shock absorber M12 80 Nm

(59 lbf ft)

Loctite

®

243™

– Mount and tighten screw .

Guideline

Screw, bottom shock

absorber

M12 80 Nm

(59 lbf ft)

Loctite

®

243™

Info

The heim joint for the shock absorber at the swing arm is Teflon coated. It

must not be greased with grease or with other lubricants. Lubricants dis-

solve the Teflon coating, thereby drastically reducing the service life.

– Remove the motorcycle from the work stand. ( p. 38)

11.15Checking the basic setting of the fork

Info

For various reasons, no exact riding sag can be determined for the forks.

400189-01

– As with the shock absorber, smaller weight differences can be compensated by the

spring preload.

– However, if your fork often bottoms out (hard end stop on compression), you must

fit harder springs to avoid damage to the fork and frame.

11.16Adjusting the compression damping of the fork

Info

The hydraulic compression damping determines the fork suspension behavior.

100020-10

(EXC, EXC SIX DAYS, XC-W)

– Remove protection covers .

– Turn adjusting screws clockwise all the way.

Info

Adjusting screws are located at the bottom end of the fork legs.

Make the same adjustment on both fork legs.

– Turn back counterclockwise by the number of clicks corresponding to the fork

type.

Guideline

(All 125/200 models)

Compression damping

Comfort 26 clicks

Standard 22 clicks

Sport 18 clicks

(All 250/300 EXC/XC-W models)

Compression damping

Comfort 26 clicks

Standard 22 clicks

Sport 18 clicks

Loading...

Loading...